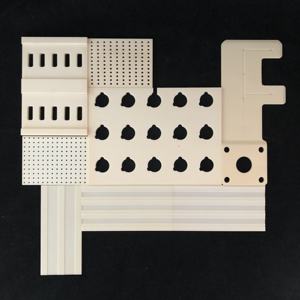

Professional Premium Aluminum Oxide Products Supplier

1. Introduction

In the past 48 hours, a viral TikTok video showcasing an ‘indestructible’ white baking dish surviving a 1,000°F oven test sparked renewed interest in high-alumina ceramics for kitchen use. While many assumed it was standard porcelain, experts confirmed it was likely an alumina ceramic baking dish—a niche but growing category in premium cookware.

Unlike everyday ceramic dishes, alumina ceramic baking dishes are engineered with high-purity aluminum oxide (Al₂O₃), offering exceptional heat resistance, non-reactivity, and durability. But how do they really stack up against traditional options? Let’s break it down.

2. What Makes Alumina Ceramic Unique?

Alumina (aluminum oxide) is a technical ceramic, not your typical pottery clay. When fired at extreme temperatures (often above 1,600°C), it becomes dense, nonporous, and incredibly stable.

This is why you’ll see the same base material used in industrial contexts—like alumina ceramic tubes for furnaces or alumina crucibles for melting metals—but when shaped into kitchenware, it transforms into safe, elegant, and ultra-durable tableware.

3. Alumina Ceramic Baking Dish vs. Standard Ceramic Bakeware

3.1. Thermal Shock Resistance

Standard ceramic baking dishes (like earthenware or low-fired stoneware) can crack under rapid temperature changes. In contrast, an alumina ceramic baking dish handles thermal shock far better due to its low coefficient of thermal expansion.

- An alumina oven ceramic dish can go straight from freezer to broiler without cracking.

- Regular ceramic casseroles often require preheating to avoid breakage.

3.2. Heat Retention and Distribution

Alumina ceramic dishes distribute heat evenly and retain it longer—ideal for slow-roasting or keeping food warm on the table. This makes items like the alumina ceramic casserole with lid perfect for lasagnas or gratins.

Meanwhile, metal pans heat quickly but cool just as fast, and porous ceramics may create hot spots.

4. Comparing Alumina Dinnerware Variants

The versatility of alumina extends beyond baking. You’ll find everything from alumina white ceramic plates to alumina black ceramic plates, all sharing the same core benefits.

Alumina ceramic plates for dinner are prized for their chip resistance and glossy finish that doesn’t degrade over time. Unlike painted porcelain, the color in alumina black plates ceramic is often integral to the material, not just a surface glaze.

Specialty items like the alumina ceramic butter dish with lid or alumina ceramic sugar dish maintain freshness thanks to their nonporous nature—no absorption of odors or moisture.

5. The Staub Confusion: Is ‘Alumina Baking Dish Staub’ Real?

Some shoppers search for ‘alumina baking dish staub,’ assuming the famous French brand uses alumina. In reality, Staub uses enameled cast iron—not alumina ceramic.

True alumina ceramic baking dishes are typically unglazed or feature food-safe, high-temperature glazes fused during sintering. They’re lighter than cast iron but offer comparable even heating—without rust or seasoning requirements.

6. Beyond the Kitchen: Why Alumina Appears in Industrial Lists

You might notice odd keyword overlaps—like ‘alumina ceramic disc taps’ or ‘alumina thermocouple protection tubes.’ These share the same raw material (high-purity Al₂O₃) but are engineered for completely different uses.

For example:

- Alumina ceramic grinding discs are used in pottery workshops to shape greenware.

- Alumina ceramic pipes handle corrosive fluids in chemical plants.

- Alumina crucibles melt gold at 1,100°C+.

These industrial forms are denser, harder, and often contain 95–99.8% alumina—far more than typical tableware (which may be 60–85%). So while your alumina ceramic serving platter and an alumina tube furnace both start as Al₂O₃ powder, their final properties diverge significantly.

7. Practical Considerations for Home Use

Are alumina ceramic dishes for oven worth the investment? For serious bakers and entertainers, yes.

Pros:

- Oven-, microwave-, and dishwasher-safe

- Non-reactive (won’t leach metals or alter flavors)

- Available as alumina ceramic ramekins, salad bowls, and even childrens plates with vibrant, fade-resistant colors

Cons:

- Higher upfront cost than standard ceramic

- Heavier than glass or thin porcelain

- Limited decorative variety compared to hand-painted options like alumina blue white porcelain plates

Still, for those seeking heirloom-quality, functional elegance—from an alumina ceramic Christmas platter to everyday alumina ceramic plates and bowls—the performance speaks for itself.

8. Conclusion

An alumina ceramic baking dish isn’t just another pretty plate—it’s a fusion of advanced materials science and culinary design. While keywords like ‘alumina ceramic disc’ or ‘alumina bricks’ point to industrial cousins, the kitchen-ready versions offer unmatched durability, safety, and thermal performance. Whether you’re roasting, serving, or storing, alumina-based ceramics deliver where ordinary tableware falls short.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as 7. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.