Professional Premium Aluminum Oxide Products Supplier

1. Introduction

Just 24 hours ago, a viral TikTok video showcasing an alumina ceramic baking dish surviving a 500°F broiler test without cracking sparked a surge in online searches for ‘alumina ceramic dishes for oven.’ Home cooks and professional chefs alike are turning to high-alumina ceramics not just for performance—but for style, sustainability, and safety.

If you’ve seen terms like ‘alumina baking ceramic dish’ or ‘alumina ceramic casserole with lid’ popping up in your feed, you’re not alone. This isn’t just another kitchen trend—it’s a materials revolution rooted in advanced ceramics. Let’s break down why alumina ceramic bakeware is worth your attention.

2. What Is an Alumina Ceramic Baking Dish?

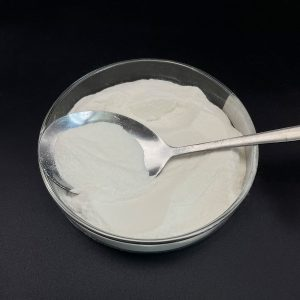

An alumina ceramic baking dish is made from aluminum oxide (Al₂O₃), a refined ceramic material known for exceptional thermal stability, hardness, and chemical inertness. Unlike traditional stoneware or porcelain, high-purity alumina ceramics can withstand extreme temperatures—often exceeding 1,600°C—making them ideal for everything from slow roasting to broiling.

These dishes are non-porous, meaning they resist staining, odors, and bacterial growth. That’s why you’ll also find related items like alumina ceramic butter dish with lid, alumina ceramic sugar dish, and even alumina ceramic ramekins gaining traction in eco-conscious kitchens.

3. Top Benefits of Cooking with Alumina Bakeware

- Even heat distribution: Alumina ceramic dishes retain and distribute heat uniformly, reducing hot spots and ensuring perfectly cooked casseroles, gratins, and baked pastas.

- Oven-to-table elegance: From sleek alumina black ceramic plates to classic alumina white ceramic plates, these pieces double as stunning serving ware—think alumina ceramic serving platter or alumina ceramic serving bowls that go straight from oven to dining table.

- Non-reactive surface: Unlike some metals, alumina doesn’t leach chemicals or alter food flavor, making it safe for acidic dishes like tomato-based sauces or citrus marinades.

- Durability: Far more chip- and scratch-resistant than standard ceramics, alumina bakeware lasts for years, even with daily use.

4. Beyond Baking: The Full Alumina Ceramic Tableware Range

While the ‘alumina ceramic baking dish’ gets the spotlight, the material shines across the entire dining experience. Brands now offer coordinated sets including alumina ceramic dinner plates, alumina ceramic plates for dinner, and even themed collections like alumina ceramic christmas plates and alumina christmas ceramic platter for holiday entertaining.

Families love alumina ceramic childrens plates for their toughness and lead-free composition. Artists appreciate alumina ceramic plates for painting due to their smooth, receptive glaze. And for everyday use, options range from minimalist alumina black plates ceramic to intricate alumina blue white porcelain plates inspired by traditional patterns.

5. Industrial Roots, Kitchen-Ready Results

It might surprise you that the same alumina used in aerospace and lab equipment—like alumina ceramic tubes for high temperature, alumina thermocouple protection tubes, and alumina ceramic crucibles—is now refined for culinary use. Manufacturers leverage decades of engineering to create food-safe, aesthetically pleasing versions.

Don’t confuse kitchen-grade alumina ceramics with raw industrial components like alumina discs, alumina grinding discs, or alumina ceramic piping. While they share the base material, foodware undergoes strict quality control for glaze safety, finish, and thermal shock resistance.

6. How to Choose the Right Alumina Ceramic Dish

When shopping, look for terms like ‘alumina ceramic casserole,’ ‘alumina oven ceramic dish,’ or ‘alumina ceramic dishes for oven’ to ensure oven compatibility. Lidded options—such as alumina ceramic casserole with lid or alumina butter dish ceramic with lid—are great for storage and moisture retention.

Avoid vague labels. True high-alumina ceramics will specify purity (typically 90–99.8% Al₂O₃) and be certified lead- and cadmium-free. Handcrafted options like alumina handcrafted ceramic plates often feature unique glazes but should still meet food-safety standards.

7. Care and Longevity Tips

Even though alumina ceramic is tough, sudden temperature changes can cause stress. Always preheat your oven and avoid placing a hot dish on a cold surface. Hand-washing is recommended to preserve glaze integrity, though many modern pieces are dishwasher-safe.

Store carefully—while resistant to chipping, stacking heavy items can still cause microfractures over time. Consider using felt pads between alumina ceramic plate bowls or alumina ceramic bowl plates if you stack them regularly.

8. Conclusion

The alumina ceramic baking dish isn’t just a kitchen tool—it’s a bridge between cutting-edge materials science and everyday culinary joy. Whether you’re serving a weeknight casserole in an alumina casserole ceramic dish or presenting holiday cookies on an alumina christmas plates ceramic platter, you’re investing in performance, beauty, and peace of mind. As this trend grows, expect to see even more innovation in alumina ceramic plates and bowls designed for both function and flair.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as 7. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.