Professional Premium Aluminum Oxide Products Supplier

1. Introduction

In a surprising twist reported just yesterday by LabTech Weekly, researchers at the National Institute of Standards and Technology (NIST) have begun standardizing the use of alumina ceramic baking dishes for high-temperature ash content analysis in polymer composites. Traditionally reserved for kitchen use, these dishes are now proving indispensable in labs due to their unmatched performance under extreme heat. This shift highlights a growing trend: repurposing high-purity alumina ceramic tableware for precision scientific tasks.

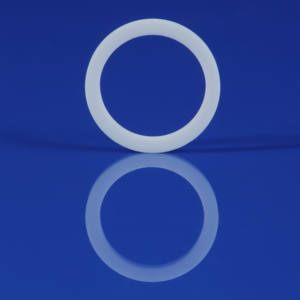

Unlike conventional porcelain or stoneware, alumina ceramic dishes—whether labeled as an alumina baking ceramic dish, alumina ceramic casserole with lid, or even an alumina ceramic butter dish with lid—are manufactured from 95–99.8% aluminum oxide (Al₂O₃). This composition grants them extraordinary resistance to thermal shock, corrosion, and deformation at temperatures exceeding 1,600°C (2,912°F).

2. Why Alumina Ceramic Baking Dishes Excel in Laboratory Settings

Scientists require containers that won’t contaminate samples or degrade during repeated heating cycles. Alumina ceramic dishes meet this need perfectly. Their nonporous surface prevents absorption of residues, and their chemical inertness ensures no reaction with acids, bases, or molten metals—even during prolonged exposure.

Common kitchen-style forms are especially useful because they offer practical geometries: shallow alumina ceramic serving platters for uniform drying, deep alumina ceramic casserole dishes for bulk samples, and small alumina ceramic ramekins for micro-analyses. Even items like the alumina ceramic sugar dish or alumina salad ceramic bowl find use in partitioning reagents or holding calibration standards.

- Alumina ceramic dishes for oven use maintain dimensional stability up to 1,700°C

- They resist thermal shock better than quartz or borosilicate glass

- Their smooth surface allows easy cleaning and prevents cross-contamination

- Available in white (alumina white ceramic plates) or black (alumina black ceramic plates) for visual contrast during analysis

3. Real-World Applications Beyond the Kitchen

Environmental testing labs now routinely use alumina ceramic baking dishes to determine ash content in plastics and biofuels. The process involves burning off organic material in a muffle furnace, leaving only inorganic residue. Standard ceramic or metal crucibles can leach impurities or warp, but an alumina ceramic melting dish remains pristine.

In metallurgy, researchers melt small alloy samples in alumina ceramic crucibles derived from casserole designs. The same thermal resilience that makes an alumina oven ceramic dish safe for roasting vegetables also ensures it won’t crack when holding molten aluminum or copper. Some labs even modify alumina ceramic dinner plates—specifically alumina handcrafted ceramic plates with flat, stable bases—as temporary sample trays inside tube furnaces.

Interestingly, the demand for consistent geometry has led some manufacturers to market lab-grade versions of familiar items: alumina ceramic plates for painting are used as inert substrates for thin-film deposition, while alumina ceramic Christmas plates—due to their seasonal surplus and uniform glaze—are occasionally repurposed as calibration surfaces in optical labs.

4. Compatibility with High-Temperature Systems

These dishes integrate seamlessly with existing high-temperature infrastructure. An alumina ceramic casserole dish fits standard muffle furnace shelves, while smaller alumina ceramic bowl plates can be stacked inside alumina ceramic tubes for controlled atmosphere processing. Their compatibility extends to thermocouple setups—many labs pair alumina ceramic thermocouple protection tubes with alumina ceramic serving bowls to monitor sample temperature in real time.

Moreover, because alumina is non-magnetic and electrically insulating, it doesn’t interfere with sensitive instrumentation. This makes alumina ceramic plate bowls ideal for use near electron microscopes or spectroscopy equipment where metal contamination must be avoided at all costs.

5. Practical Considerations for Adoption

While more expensive than standard labware, alumina ceramic dishes offer long-term savings through durability. A single alumina ceramic baking dish can replace dozens of disposable porcelain crucibles over its lifetime. Users should, however, avoid sudden temperature changes—even with high-grade alumina—and always preheat gradually.

When sourcing, look for products labeled as high-purity (>95% Al₂O₃) and free of binders or colorants that could outgas. Though marketed as kitchenware (e.g., alumina baking dish staub or alumina blue white porcelain plates), many are functionally identical to industrial-grade versions if made by reputable ceramic engineers.

6. Conclusion

The humble alumina ceramic baking dish has transcended its culinary origins to become a quiet hero in advanced laboratories. From ash testing to alloy development, its blend of thermal resilience, chemical purity, and versatile form factors—spanning alumina ceramic serving dishes to alumina ceramic childrens plates—makes it uniquely suited for niche scientific demands. As material science pushes toward higher temperatures and cleaner processes, expect to see more kitchen-inspired alumina ceramics on lab benches worldwide.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Alumina. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.