Professional Premium Aluminum Oxide Products Supplier

(Alumina Ceramic Balls)

1. Why Alumina Ceramic Balls Have Good Characteristics

1.1. High Hardness and Wear Resistance

Alumina ceramic balls are renowned for their exceptional hardness, typically ranging from 9 to on the Mohs scale. This high hardness translates directly into excellent wear resistance, making them ideal for applications involving abrasive materials or high-friction environments. The strong atomic bonds within the alumina structure resist deformation and erosion, ensuring a long service life and minimizing the need for frequent replacements. This characteristic is particularly crucial in industries like grinding, polishing, and bearing manufacturing, where components are subjected to continuous wear and tear. The superior wear resistance of alumina ceramic balls contributes significantly to reduced downtime and maintenance costs in these applications.

1.2. Excellent Chemical Inertness

Alumina (Al2O3) is chemically inert in most environments, exhibiting high resistance to corrosion and degradation from acids, alkalis, and organic solvents. This inertness makes alumina ceramic balls suitable for applications in the chemical, pharmaceutical, and food processing industries, where contamination must be avoided. Unlike metallic materials that can corrode and leach into the surrounding medium, alumina ceramic balls maintain their integrity and purity. This prevents unwanted reactions or alterations to the materials they come into contact with. The chemical stability of alumina ensures the reliability and safety of processes involving corrosive or sensitive substances.

1.3. High-Temperature Stability

Alumina ceramic balls possess remarkable high-temperature stability, maintaining their mechanical properties and structural integrity even at elevated temperatures. They can withstand temperatures up to 1000°C (1832°F) or higher, depending on the specific grade of alumina. This characteristic makes them suitable for high-temperature applications, such as furnace rollers, kiln furniture, and thermal insulation components. The ability to retain their shape and strength at high temperatures prevents deformation and ensures consistent performance in demanding thermal environments. The high-temperature stability of alumina ceramic balls is essential for maintaining the efficiency and reliability of high-temperature industrial processes.

2. What Are Alumina Ceramic Balls

2.1. Composition and Purity

Alumina ceramic balls are spheres made from aluminum oxide (Al2O3), commonly known as alumina. The purity of the alumina used in their manufacture significantly affects their properties and performance. High-purity alumina (99% or higher) results in balls with superior hardness, wear resistance, and chemical inertness. Lower-purity alumina may contain impurities that can compromise these characteristics. The manufacturing process is carefully controlled to ensure uniform composition and density throughout each ball. This uniformity is critical for consistent performance in applications where precise and predictable behavior is required. Alumina ceramic balls are available in various grades, each tailored to specific application requirements.

2.2. Key Properties

Alumina ceramic balls exhibit a unique combination of properties that make them valuable in various applications. Their key properties include high hardness, excellent wear resistance, chemical inertness, high-temperature stability, electrical insulation, and low density compared to steel. These properties make them suitable for use in demanding environments where other materials may fail. For example, their electrical insulation properties make them useful in electronic components, while their low density can reduce the weight of machinery. The specific properties of alumina ceramic balls can be further tailored by adjusting the composition and manufacturing process to meet the needs of different applications.

2.3. Types and Grades

Alumina ceramic balls are available in various types and grades, each designed for specific applications. Common types include high-alumina balls (90% Al2O3 or higher), medium-alumina balls (70-90% Al2O3), and low-alumina balls (less than 70% Al2O3). High-alumina balls offer superior performance in terms of hardness, wear resistance, and chemical inertness, while lower-alumina balls may be more cost-effective for less demanding applications. Different grades of alumina ceramic balls are also available, based on factors such as grain size, porosity, and surface finish. These variations allow engineers and designers to select the most appropriate type and grade of alumina ceramic balls for their specific needs, optimizing performance and cost-effectiveness.

3. How Alumina Ceramic Balls Are Produced

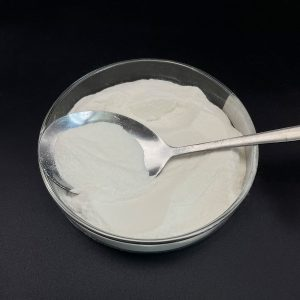

3.1. Raw Material Preparation

The production of alumina ceramic balls begins with the selection and preparation of high-quality alumina powder as the raw material. The alumina powder must have a controlled particle size distribution and a high level of purity to ensure the desired properties in the final product. Impurities can negatively impact the mechanical strength and chemical resistance of the ceramic balls. The raw material preparation process typically involves milling and blending the alumina powder with binders and additives to form a homogeneous mixture. These binders and additives help to improve the workability of the powder during the subsequent forming process. Careful control of the raw material preparation stage is crucial for achieving consistent and reliable results in the finished alumina ceramic balls.

3.2. Forming Process

The prepared alumina powder mixture is then formed into spherical shapes using various techniques, including extrusion, pressing, or slip casting. Extrusion involves forcing the mixture through a die to create cylindrical shapes, which are then cut into pellets and rounded into balls. Pressing involves compacting the powder in a mold under high pressure to form the desired shape. Slip casting involves pouring a slurry of the powder into a porous mold, allowing the water to be absorbed, leaving a solid layer of alumina on the mold walls. Each forming technique has its advantages and disadvantages in terms of production rate, dimensional accuracy, and cost. The choice of forming process depends on the specific requirements of the application and the desired characteristics of the alumina ceramic balls.

3.3. Sintering and Finishing

After forming, the green alumina ceramic balls undergo a sintering process to consolidate the particles and increase their density and strength. Sintering involves heating the balls to a high temperature (typically between 1500°C and 1700°C) in a controlled atmosphere. This process causes the alumina particles to fuse together, reducing porosity and increasing the overall strength of the material. After sintering, the alumina ceramic balls may undergo a finishing process to improve their surface finish and dimensional accuracy. This can involve grinding, polishing, or lapping to achieve the desired smoothness and precision. The sintering and finishing processes are critical for achieving the final properties and performance characteristics of the alumina ceramic balls.

4. What Are The Application Fields of Alumina Ceramic Balls

4.1. Grinding and Milling

Alumina ceramic balls are extensively used as grinding media in various milling processes. Their high hardness and wear resistance make them ideal for grinding and dispersing materials in industries such as ceramics, paints, pharmaceuticals, and electronics. In ball mills, the alumina balls collide with the material being ground, breaking it down into smaller particles. Their chemical inertness prevents contamination of the milled material, ensuring product purity. The controlled size and density of the alumina balls allow for precise control over the grinding process, achieving consistent particle size distribution. Alumina grinding media provides a cost-effective and efficient solution for a wide range of milling applications, from laboratory-scale experiments to large-scale industrial production.

4.2. Bearings and Valves

Alumina ceramic balls find applications in bearings and valves, particularly in demanding environments where traditional materials may fail. Their high hardness, wear resistance, and chemical inertness make them suitable for use in corrosive, high-temperature, or high-speed applications. In bearings, alumina balls provide smooth and low-friction rolling surfaces, reducing wear and extending the lifespan of the bearing. In valves, they serve as sealing elements, providing a tight and reliable seal even in the presence of abrasive or corrosive fluids. Alumina ceramic balls offer superior performance compared to steel balls in these applications, reducing maintenance costs and improving operational efficiency. Examples include use in chemical pumps and high-precision instruments.

4.3. Polishing and Surface Treatment

Alumina ceramic balls are also used as polishing media in surface treatment processes. Their controlled size and hardness allow for precise and uniform polishing of various materials, including metals, ceramics, and plastics. In vibratory finishing or tumbling processes, the alumina balls gently abrade the surface of the workpiece, removing imperfections and creating a smooth, polished finish. Their chemical inertness prevents contamination of the workpiece, maintaining its integrity and appearance. Alumina ceramic balls offer a cost-effective and environmentally friendly alternative to traditional polishing compounds, reducing waste and improving the quality of the finished product. These are often used for polishing jewelry, lenses, and electronic components.

5. How To Choose A Good Alumina Ceramic Balls

5.1. Material Purity and Composition

When selecting alumina ceramic balls, the material purity and composition are crucial factors to consider. High-purity alumina (99% or higher) is generally preferred for demanding applications requiring superior hardness, wear resistance, and chemical inertness. Lower-purity alumina may contain impurities that can compromise these characteristics, leading to reduced performance and lifespan. The specific composition of the alumina ceramic balls can also affect their properties. For example, the addition of certain dopants can improve their thermal conductivity or electrical insulation. Therefore, it is essential to carefully review the material specifications and choose alumina ceramic balls with the appropriate purity and composition for the intended application.

5.2. Size and Tolerance

The size and tolerance of alumina ceramic balls are critical parameters that must be considered based on the application requirements. The size of the balls directly affects their performance in grinding, polishing, and bearing applications. The tolerance, or the allowable variation in size, determines the precision and consistency of the application. For example, in high-precision bearings, it is essential to use alumina ceramic balls with tight tolerances to ensure smooth and reliable operation. In grinding applications, the size of the balls affects the grinding efficiency and the particle size distribution of the milled material. Therefore, it is important to specify the appropriate size and tolerance for the alumina ceramic balls to achieve the desired performance and accuracy.

5.3. Supplier Reputation and Quality Control

Choosing a reputable supplier with robust quality control procedures is essential when selecting alumina ceramic balls. A reliable supplier will have a track record of providing high-quality products that meet the specified requirements. They will also have in-house testing facilities and quality control processes to ensure the consistency and reliability of their products. Look for suppliers who can provide certificates of analysis (COA) or other documentation to verify the material purity, composition, and dimensional accuracy of their alumina ceramic balls. By selecting a reputable supplier, you can minimize the risk of receiving substandard products that could compromise the performance and reliability of your application.

6. What Does People Also Ask About Alumina Ceramic Balls

6.1. What is the lifespan of alumina ceramic balls?

The lifespan of alumina ceramic balls varies depending on the application, operating conditions, and the quality of the balls. In general, alumina ceramic balls are known for their excellent wear resistance and long service life compared to other materials. In abrasive grinding applications, the lifespan may be shorter due to the constant friction and impact forces. However, in less demanding applications such as bearings or valves, they can last for many years with minimal degradation. Factors that can affect the lifespan include the operating temperature, the presence of corrosive substances, and the load applied to the balls. Regular inspection and maintenance can help to extend the lifespan of alumina ceramic balls and ensure optimal performance.

6.2. Are alumina ceramic balls electrically conductive?

Alumina (Al2O3) in its pure form is an excellent electrical insulator. Therefore, alumina ceramic balls are typically used in applications where electrical insulation is required. However, the electrical conductivity can be affected by the presence of impurities or dopants in the alumina. Some grades of alumina ceramic balls may have slightly higher conductivity due to the addition of specific additives. However, even in these cases, the conductivity is still relatively low compared to metals or semiconductors. Therefore, alumina ceramic balls are generally considered to be electrically non-conductive and suitable for applications where electrical isolation is important. This property is particularly useful in electronic components and high-voltage applications.

6.3. How do alumina ceramic balls compare to steel balls?

Alumina ceramic balls offer several advantages over steel balls in certain applications. Alumina ceramic balls have higher hardness, wear resistance, and chemical inertness than steel balls. They are also lighter in weight and can withstand higher temperatures. However, steel balls typically have higher tensile strength and impact resistance than alumina ceramic balls. Therefore, the choice between alumina ceramic balls and steel balls depends on the specific requirements of the application. Alumina ceramic balls are preferred for applications where wear resistance, chemical inertness, and electrical insulation are critical, while steel balls are preferred for applications where high strength and impact resistance are required.

Tags: alumina ceramic balls, ceramic balls, alumina, grinding media, bearings, valves, polishing, technical ceramics, high alumina, material properties

(Alumina Ceramic Balls)

Supplier

Alumina Technology Co., Ltd focus on the research and development, production and sales of aluminum oxide powder, aluminum oxide products, aluminum oxide crucible, etc., serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services. If you are looking for high quality Alumina Ceramic Products , please feel free to contact us. (nanotrun@yahoo.com)