Professional Premium Aluminum Oxide Products Supplier

1 Key Physical and Technical Specifications

Standard alumina tubes feature wall thicknesses from 0.5mm to 20mm, with diameters ranging from 1mm to 300mm. Their density typically falls between 3.6-3.9 g/cm³ depending on purity, correlating with mechanical strength. Technical specifications include thermal expansion coefficients of 7-8.5 × 10⁻⁶/K (25-800°C) and thermal conductivity of 18-30 W/(m·K). Surface finishes range from as-fired to precision-polished (Ra ≤ 0.2μm), with dimensional tolerances as tight as ±0.1% for high-grade tubes. These parameters determine suitability for specific industrial applications.

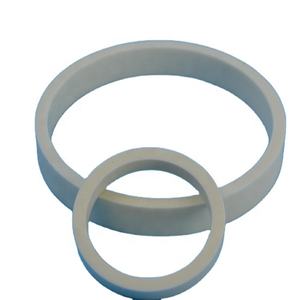

(Alumina Ceramic Tube)

1.2 Superior Mechanical Strength and Wear Resistance

With a Vickers hardness rating of 15-20 GPa, alumina ceramic tubes demonstrate remarkable resistance to abrasion and mechanical wear. Their fine-grained microstructure minimizes surface defects that could initiate cracks, while high compressive strength (2,000-4,000 MPa) withstands significant loads. This durability reduces maintenance frequency in high-friction applications like material conveying systems. The material’s stiffness (Young’s modulus 300-400 GPa) also prevents deformation under stress, maintaining dimensional stability in precision instruments and industrial machinery components.

1.3 Excellent Electrical Insulation Properties

Alumina ceramic tubes serve as exceptional electrical insulators with volume resistivity exceeding 10^14 Ω·cm even at elevated temperatures. This dielectric strength prevents current leakage in high-voltage applications like spark plugs, insulators, and semiconductor manufacturing equipment. Unlike polymers, alumina maintains insulation properties up to 1000°C, making it indispensable in high-temperature electrical systems. The material’s low dielectric loss tangent ensures minimal energy dissipation in radiofrequency applications, while its thermal conductivity facilitates heat dissipation from enclosed electrical components.

2 What Is Alumina Ceramic Tube

2.1 Composition and Material Structure

Alumina ceramic tubes consist primarily of aluminum oxide (Al₂O₃), typically containing 92-99.9% purity. Higher purity grades exhibit enhanced properties but require more complex manufacturing. The crystalline α-alumina phase forms a hexagonal close-packed structure through sintering, creating dense, pore-free tubes. Trace elements like silica or magnesia may be added to control grain growth during firing. This polycrystalline structure provides isotropic properties, meaning the tubes maintain consistent performance characteristics regardless of orientation, which is crucial for precision engineering applications.

2.2 Key Physical and Technical Specifications

Standard alumina tubes feature wall thicknesses from 0.5mm to 20mm, with diameters ranging from 1mm to 300mm. Their density typically falls between 3.6-3.9 g/cm³ depending on purity, correlating with mechanical strength. Technical specifications include thermal expansion coefficients of 7-8.5 × 10⁻⁶/K (25-800°C) and thermal conductivity of 18-30 W/(m·K). Surface finishes range from as-fired to precision-polished (Ra ≤ 0.2μm), with dimensional tolerances as tight as ±0.1% for high-grade tubes. These parameters determine suitability for specific industrial applications.

3 How Alumina Ceramic Tube Was Produced?

3.1 Powder Processing and Forming Techniques

Manufacturing begins with high-purity alumina powder milling to achieve submicron particle size distribution. Binders and plasticizers are added to create a moldable compound. Tubes are formed through extrusion (for complex profiles), isostatic pressing (for uniform density), or slip casting (for large diameters). Extrusion forces material through shaped dies under high pressure, while isostatic pressing applies uniform hydraulic pressure to powder in elastomeric molds. Slip casting involves pouring liquid slurry into porous plaster molds. Each method affects final microstructure and requires precise control of parameters like moisture content and pressure.

3.2 Sintering and Finishing Processes

Green-formed tubes undergo binder burnout at 400-600°C before high-temperature sintering between 1600-1800°C. This diffusion-driven process densifies the material, reducing porosity to less than 1%. Temperature profiles and dwell times critically influence grain growth and final properties. Post-sintering, precision grinding achieves tight tolerances using diamond tools. Optional processes include laser drilling for micro-holes, metallization for brazing, or surface polishing. Quality verification involves dimensional checks, density measurements, and non-destructive testing like ultrasonic inspection for internal flaws.

4 What Are The Application Fields of Alumina Ceramic Tube

4.1 High-Temperature Industrial Systems

Alumina tubes serve as essential components in thermal processing equipment, functioning as thermocouple protection sheaths in furnaces operating up to 1800°C. Their thermal shock resistance allows rapid temperature cycling in heat treatment applications. In semiconductor manufacturing, ultra-high-purity tubes transport reactive gases during chemical vapor deposition. The ceramics industry utilizes them as kiln furniture supports for firing advanced materials. Their non-reactivity makes them ideal for molten metal handling, particularly in aluminum smelting where they function as transfer tubes and degassing rotors.

4.2 Electronics and Advanced Technology

In electronics, alumina tubes provide hermetic enclosures for high-power vacuum tubes and insulators for high-voltage equipment. Their dielectric properties enable use in plasma etching systems for wafer fabrication. Medical applications include X-ray tube housings and insulators in diagnostic imaging equipment. Research laboratories employ transparent alumina tubes for high-pressure sodium lamp envelopes and laser containment. Emerging applications include protective sheaths for fiber optic sensors in harsh environments and substrates for thin-film deposition in renewable energy technologies.

5 How To Choose A Good Alumina Ceramic Tube

5.1 Material Grade Selection Criteria

Select alumina purity based on application requirements: 95-97% alumina offers cost-effectiveness for general industrial use, while 99.5-99.9% grades provide superior corrosion resistance for semiconductor or pharmaceutical applications. Verify density (>3.7 g/cm³) through manufacturer certificates, as higher density correlates with improved mechanical properties. For thermal cycling applications, prioritize tubes with controlled grain size (typically 3-10μm) to enhance thermal shock resistance. Consider specialized formulations like zirconia-toughened alumina if impact resistance is critical.

5.2 Performance Validation and Compliance

Require documentation of mechanical testing including flexural strength (>300 MPa), hardness (>80 HRA), and Weibull modulus data indicating reliability consistency. For high-voltage applications, confirm dielectric strength (>15 kV/mm) and volume resistivity specifications. Validate dimensional tolerances against ISO 286 or ASME standards. Check for industry-specific certifications like ISO 9001 for quality management or USP Class VI for medical applications. Conduct on-site verification of surface finish using profilometers and inspect for microcracks using dye-penetrant testing methods.

6 What Does People Also Ask About Alumina Ceramic Tube

6.1 Performance and Durability Concerns

Common questions focus on thermal shock limits: alumina tubes typically withstand ΔT of 200-250°C depending on wall thickness and grain structure. Users inquire about maximum continuous operating temperatures (1600-1750°C for high-purity grades). Impact resistance is frequently questioned – alumina’s brittleness requires careful handling, though fracture toughness can reach 4-5 MPa·m½. Concerns about chemical compatibility arise; high-purity alumina resists all acids except hydrofluoric and strong caustics above 100°C. Longevity expectations vary, but properly specified tubes can last 5-10 years in continuous industrial service.

6.2 Installation and Handling Best Practices

Installation queries emphasize proper mounting techniques to avoid point stresses: use compliant gaskets and allow thermal expansion (0.8% at 1000°C). Frequently asked questions address cleaning methods – recommend ultrasonic cleaning with neutral pH solutions rather than abrasive techniques. Users seek guidance on joining methods; metallized tubes allow brazing, while mechanical clamping suits non-hermetic applications. Handling precautions include using protective coatings during transport to prevent surface damage and avoiding thermal gradients exceeding 200°C/minute during startup/shutdown cycles to prevent thermal fracture.

(Alumina Ceramic Tube)

Tags: alumina ceramic tube, alumina tube properties, ceramic tube manufacturing, high temperature ceramic tubes, industrial ceramic tubes, alumina tube applications, ceramic tube selection, alumina 99.7% tube, technical ceramic tubing

Supplier

Alumina Technology Co., Ltd focus on the research and development, production and sales of aluminum oxide powder, aluminum oxide products, aluminum oxide crucible, etc., serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services. If you are looking for high quality Alumina Ceramic Products , please feel free to contact us. (nanotrun@yahoo.com)