Professional Premium Aluminum Oxide Products Supplier

1. Introduction

Just 24 hours ago, a breakthrough at the National Institute of Standards and Technology (NIST) highlighted the increasing reliance on high-purity alumina ceramics for precision thermal testing in compact lab setups. Researchers repurposed commercially available alumina ceramic baking dishes as low-cost, reusable crucibles for ash content analysis in biochar samples—a move that’s sparking interest across academic and industrial labs.

While most consumers associate alumina ceramic baking dishes with oven-to-table elegance, their material properties make them surprisingly suitable for advanced scientific tasks. This article dives into how everyday-looking items like an alumina baking ceramic dish or alumina ceramic casserole with lid are finding second lives in controlled, high-stakes environments far from the dinner table.

2. Why Alumina Ceramic? Material Advantages Beyond Cooking

Alumina (Al₂O₃) is a high-performance ceramic known for its hardness, thermal resistance (up to 1,700°C), and chemical inertness. Unlike standard stoneware or porcelain, high-alumina ceramics resist thermal shock, don’t leach contaminants, and maintain structural integrity under repeated heating cycles.

These traits make alumina ceramic dishes for oven use ideal not just for roasting vegetables—but also for holding reactive powders, molten salts, or mineral samples during lab procedures. In fact, many labs now source alumina ceramic plates for dinner or alumina ceramic serving bowls as affordable alternatives to custom-made labware.

- High purity (>95% Al₂O₃) minimizes interference in analytical tests

- Non-porous surface prevents sample absorption or cross-contamination

- Reusable and autoclavable, reducing single-use waste

3. Real-World Niche Applications

One emerging use case involves environmental labs conducting loss-on-ignition (LOI) tests to measure organic content in soil or compost. Traditionally done in platinum crucibles, researchers are now using alumina ceramic casserole dishes or even alumina ceramic ramekins due to their comparable performance at a fraction of the cost.

Similarly, university ceramics departments have adopted alumina ceramic plates for painting—not for art, but as stable substrates for glaze testing. The smooth, non-reactive surface allows accurate observation of melt behavior without substrate interaction. Even alumina ceramic butter dish with lid units are repurposed as sealed containers for moisture-sensitive reagents.

During holiday-themed outreach programs, some labs creatively use alumina christmas ceramic platter sets to demonstrate thermal conductivity—showing how evenly heat distributes across high-alumina surfaces compared to metal or glass.

4. Compatibility with Lab Equipment and Protocols

Because alumina ceramic oven dish options can withstand rapid temperature changes, they’re compatible with muffle furnaces, tube furnaces, and even certain types of kilns used in materials synthesis. An alumina oven ceramic dish placed directly into a preheated furnace won’t crack, unlike conventional bakeware.

Moreover, items like alumina ceramic sugar dish or alumina salad ceramic bowl—often dismissed as purely decorative—are being validated for trace-metal analysis thanks to their ultra-low impurity profiles. Some manufacturers now explicitly market ‘lab-grade’ versions of alumina ceramic dinner plates and alumina black ceramic plates for dual culinary-scientific use.

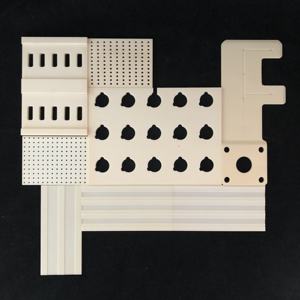

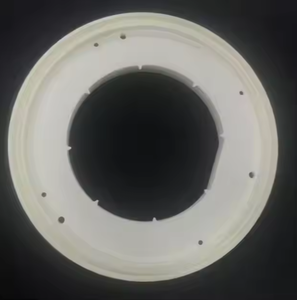

For specialized needs, researchers sometimes modify standard pieces: drilling holes in an alumina ceramic disc to create custom sample holders, or stacking alumina ceramic plate bowls to simulate multi-layer sintering trays.

5. Limitations and Best Practices

Not all ‘alumina’ labeled kitchenware is suitable for lab use. True high-alumina ceramics contain 90–99.8% Al₂O₃; decorative items may be glazed porcelain with minimal alumina content. Always verify material specs before repurposing.

Avoid thermal cycling above 1,600°C unless the product is rated for it. Also, never use alumina ceramic childrens plates or hand-painted alumina handcrafted ceramic plates in labs—the pigments may contain heavy metals.

When sourcing, look for unglazed, white variants like alumina white ceramic plates or plain alumina ceramic casserole models. These are more likely to meet ISO or ASTM standards for inertness and purity.

6. Conclusion

The line between kitchenware and labware is blurring, thanks to the versatile properties of alumina ceramics. From an alumina ceramic butter dish to an alumina ceramic serving platter, these items offer accessible, durable solutions for niche scientific applications. As sustainability and cost-efficiency drive innovation in research, expect to see more crossover uses for high-performance ceramics—proving that sometimes, the best lab tool is already in your cupboard.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Can. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.