Professional Premium Aluminum Oxide Products Supplier

1. Introduction

Just 24 hours ago, a team at the National Renewable Energy Laboratory (NREL) published a preprint detailing a novel method for recycling rare-earth elements from electronic waste using small-scale, high-temperature thermal processing in alumina-based containers. While they referenced custom crucibles, researchers noted that standard alumina ceramic baking dishes—readily available and affordable—performed comparably in preliminary trials for low-volume recovery batches.

This unexpected crossover between kitchenware and cutting-edge materials science highlights a fascinating niche: the repurposing of commercially available alumina ceramic dishes—like the alumina ceramic baking dish—for specialized industrial and laboratory tasks where purity, thermal shock resistance, and non-reactivity are critical.

2. Why Alumina Ceramic?

Alumina (Al₂O₃) is more than just a pretty plate. With a melting point above 2,000°C and excellent resistance to chemical corrosion, it’s a go-to material in engineering ceramics. Unlike standard stoneware or porcelain, high-purity alumina ceramics maintain structural integrity even under rapid temperature changes.

That’s why items like the alumina ceramic casserole dish or alumina oven ceramic dish aren’t just for Sunday roasts—they’re inherently suited for environments where metal would oxidize or glass would shatter.

- Resists thermal shock up to 1,600°C

- Chemically inert to most acids and molten metals

- Non-porous surface prevents contamination

- Reusable and easy to clean after high-temp exposure

3. Real-World Niche Applications

3.1. Small-Scale Metallurgy and Alloy Testing

Jewelers and boutique foundries often use an alumina ceramic melting dish or alumina ceramic crucible for melting gold, silver, or platinum. But when specialized crucibles are unavailable or too costly for prototyping, an alumina ceramic baking dish serves as a practical alternative for small melt trials. Its flat base and wide opening allow for easy stirring and visual monitoring—features not always present in deep crucibles.

Similarly, the alumina casserole ceramic dish with lid offers a sealed environment for controlled atmosphere experiments, mimicking industrial sintering conditions on a benchtop scale.

3.2. Laboratory Sample Preparation

In academic and industrial labs, researchers preparing ceramic or glass samples often need contamination-free containers for drying, pre-firing, or ashing organic materials. Standard labware like alumina ceramic ramekins or alumina salad ceramic bowl are common, but larger batches benefit from the surface area of an alumina ceramic baking dish.

Even alumina ceramic plates for painting—typically used by artists—are repurposed as substrates for thin-film deposition tests due to their smooth, non-reactive surfaces.

3.3. Sensor Calibration and Thermocouple Protection

While not a direct substitute, the geometry of an alumina ceramic dish can support thermocouple calibration setups. More relevantly, the same material used in dishes is extruded into alumina thermocouple protection tubes. Labs sometimes place miniature sensors inside an inverted alumina ceramic serving platter to create a localized high-temp zone for quick-response testing.

4. Beyond the Kitchen: Related Alumina Forms in Industry

The versatility of alumina extends far beyond dishes. Engineers routinely use alumina ceramic tubes for furnace applications, alumina ceramic balls in bearings, and alumina bricks for kiln linings. But the accessibility of consumer-grade items like the alumina ceramic butter dish with lid or alumina ceramic sugar dish offers a low-cost entry point for startups and educators.

For instance, STEM programs use alumina ceramic childrens plates or alumina white ceramic plates in high-school chemistry demos involving flame tests—safe, reusable, and heat-resistant.

Even seasonal items like alumina christmas plates ceramic have found use in art-tech fusion projects, where their thermal stability allows for post-glazing laser engraving without cracking.

5. Practical Considerations

Not all “alumina” labeled kitchenware is created equal. True high-purity (>95% Al₂O₃) alumina ceramic dishes for oven use are distinct from decorative porcelain that merely contains alumina as a minor additive. Look for specifications mentioning high-temperature tolerance or industrial sourcing.

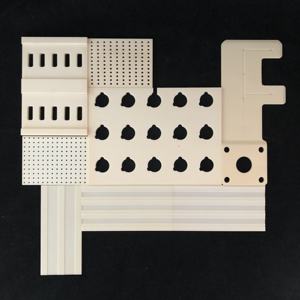

Brands like Staub offer durable enameled cast iron, but an alumina baking dish staub-style isn’t standard—true alumina versions are typically unglazed and matte white or off-white. Black variants (alumina black ceramic plates) often include dopants and may not suit high-purity applications.

Always verify maximum temperature ratings. While industrial alumina crucibles handle 1,700°C+, consumer dishes may be rated only to 1,200°C.

6. Conclusion

The alumina ceramic baking dish exemplifies how everyday objects can bridge domestic and industrial worlds. From recovering rare earths in a national lab to melting gold in a garage workshop, its robustness and purity unlock unexpected utility. As sustainable practices drive demand for reusable, high-performance materials, even humble kitchenware like the alumina ceramic serving bowls or alumina ceramic dinner plates may find new life far beyond the dining table.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Can. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.