Professional Premium Aluminum Oxide Products Supplier

1. Introduction

In the past 48 hours, a viral post on Reddit’s r/chemistry sparked debate when a researcher shared photos of using a repurposed alumina ceramic baking dish as a makeshift high-temperature container for ashing organic samples at 1,100°C. While unconventional, the post highlighted a little-known crossover between domestic ceramics and industrial-grade alumina applications. Though most consumers associate ‘alumina ceramic baking dish’ with oven-to-table dinnerware, its material properties—rooted in over 95% aluminum oxide (Al₂O₃)—align closely with those of technical ceramics used in labs and manufacturing.

This raises an intriguing question: Can kitchen-grade alumina ceramic dishes truly serve in advanced scientific contexts? The answer isn’t a simple yes or no—but understanding the nuances reveals surprising utility in specific, controlled scenarios.

2. Why Alumina? Material Properties That Matter

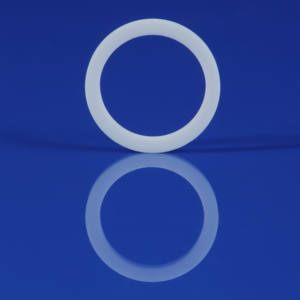

Alumina (Al₂O₃) is prized in engineering for its hardness, electrical insulation, and resistance to thermal shock and corrosion. High-purity alumina ceramics can withstand temperatures up to 1,700°C, far exceeding standard stoneware or porcelain. When manufacturers produce an ‘alumina ceramic casserole with lid’ or ‘alumina oven dish ceramic’ using dense, high-alumina formulations, they inadvertently create vessels that mimic lab crucibles in performance—though not always in certification or dimensional precision.

Unlike typical ceramic dinnerware, which may contain fluxes and colorants that degrade under extreme heat, true alumina-based kitchen items—especially those marketed as ‘alumina ceramic dishes for oven’ use—often avoid such additives. This makes them chemically inert enough for non-critical lab tasks like drying salts, pre-firing powders, or holding reference materials during calibration.

3. Real-World Niche Application: Sample Preparation in Academic Labs

One emerging niche use is in university teaching labs where budget constraints limit access to expensive platinum or zirconia crucibles. Instructors have begun sourcing ‘alumina ceramic ramekins’ or ‘alumina ceramic melting dish’ variants from specialty kitchen suppliers for student experiments involving low-risk thermal decomposition.

For instance, an alumina ceramic butter dish with lid—when verified to be pure white and unglazed on the interior—can double as a covered container for moisture-sensitive reagents during gentle heating. Similarly, an ‘alumina ceramic serving platter’ with thick walls provides a stable, flat surface for annealing thin films or drying filter papers without warping.

Crucially, these applications rely on verifying the product’s composition. Not all ‘alumina’ labeled kitchenware contains high-purity alumina; some merely use alumina as a minor component in glazes. True utility comes only from dense, unglazed, high-alumina-content pieces—often identifiable by their stark white color and weight.

4. Limitations and Safety Considerations

Despite their promise, alumina ceramic baking dishes are not certified for analytical or industrial processes. They lack traceability, standardized porosity control, and may contain microscopic impurities that contaminate sensitive reactions. For example, using an ‘alumina ceramic salad bowl’ to melt gold would risk introducing sodium or iron residues, skewing assay results.

- Never use decorated or colored versions (e.g., ‘alumina blue white porcelain plates’ or ‘alumina black ceramic plates’) in lab settings—the pigments often contain metals that volatilize at high temps.

- Avoid thermal cycling beyond manufacturer specs; even high-alumina ceramics can crack if heated too rapidly.

- Always confirm with the vendor whether the item is made from ≥90% Al₂O₃ and is fully vitrified (nonporous).

For critical applications like thermocouple sheathing or furnace linings, purpose-built components like ‘alumina thermocouple protection tubes’ or ‘alumina ceramic pipes’ remain essential. But for educational demos or preliminary trials, repurposed alumina kitchenware offers a cost-effective stopgap.

5. Beyond the Lab: Unexpected Cross-Industry Utility

The versatility extends further. Art conservators have used ‘alumina ceramic plates for painting’ as inert palettes for mixing archival-quality pigments, leveraging the material’s non-reactivity. Meanwhile, small-batch ceramic studios employ ‘alumina ceramic grinding disc’ tools alongside ‘alumina diamond grinding disc for pottery’ to shape their own high-alumina creations—sometimes even crafting custom ‘alumina ceramic Christmas plates’ that double as test tiles for glaze compatibility at elevated temperatures.

Even plumbing innovations borrow from this synergy: ‘alumina ceramic disc taps’ and ‘alumina quarter turn taps’ rely on the same wear-resistant alumina discs found in industrial valves—proving that the line between household and high-tech alumina ceramics is thinner than it appears.

6. Conclusion

While you won’t find ‘alumina ceramic dinner plates’ listed in a lab supply catalog anytime soon, their underlying material science opens doors to creative, low-stakes applications in education, art, and prototyping. The key lies in discernment: choosing unglazed, high-purity, undecorated pieces like a plain ‘alumina white ceramic plate’ or ‘alumina ceramic casserole dish’ ensures safety and functionality. So next time you see an ‘alumina baking dish Staub’-style vessel, remember—it might just belong in more than your kitchen.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Can. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.