Professional Premium Aluminum Oxide Products Supplier

1. Introduction

In the past 48 hours, a surge in online searches for non-toxic, oven-safe bakeware has spotlighted alumina ceramic baking dishes as a top choice among health-conscious home cooks. Platforms like Amazon and specialty kitchenware retailers report increased traffic for terms like ‘alumina ceramic dishes for oven’ and ‘alumina baking dish staub,’ reflecting a broader trend toward durable, chemical-free cookware.

Alumina ceramic—made primarily from aluminum oxide (Al₂O₃)—is prized not just in industrial applications but increasingly in culinary settings. Unlike standard porcelain or stoneware, high-alumina ceramics offer superior thermal shock resistance, even heating, and exceptional durability. This deep dive unpacks what makes alumina ceramic baking dishes stand out and how to choose the right type for your needs.

2. What Makes Alumina Ceramic Unique?

Alumina ceramic is a high-performance engineered material containing 90–99.8% aluminum oxide. This composition gives it remarkable hardness, chemical inertness, and thermal stability—properties that translate beautifully to kitchen use.

Compared to traditional ceramic bakeware, alumina-based dishes handle rapid temperature changes without cracking. They’re also non-porous, preventing odor absorption and bacterial growth. That’s why products like the alumina ceramic butter dish with lid or alumina ceramic casserole with lid maintain freshness and hygiene better than porous alternatives.

3. Types of Alumina Ceramic Bakeware

The versatility of alumina ceramic extends across a wide range of kitchenware. Here’s how different forms serve distinct culinary purposes:

- Alumina ceramic baking dish and alumina oven ceramic dish: Ideal for roasting, baking casseroles, or broiling due to even heat distribution and high-temperature tolerance (often exceeding 1,600°C in industrial grades, though kitchenware is rated for typical oven use up to 260–300°C).

- Alumina ceramic casserole dish and alumina casserole ceramic dish: Often come with tight-fitting lids, perfect for slow-cooked meals or oven-to-table serving.

- Alumina ceramic serving bowls and alumina ceramic serving platter: Used for both hot and cold dishes, thanks to thermal stability and elegant finishes like alumina white ceramic plates or alumina black ceramic plates.

- Alumina ceramic ramekins and alumina ramekin ceramic: Small, precise vessels for custards, soufflés, or individual portions—retaining heat without scorching edges.

- Alumina ceramic plates for dinner, including alumina dinner ceramic plates and alumina ceramic plates black: Offer scratch resistance and a refined aesthetic, whether matte black or classic white.

- Seasonal items like alumina ceramic christmas plates and alumina christmas ceramic platter: Combine festive design with functional durability.

4. Alumina vs. Standard Ceramic: A Practical Comparison

While all ceramics share some traits, alumina stands apart in performance. Standard earthenware or porcelain may chip easily or crack under thermal stress. Alumina ceramic dishes for oven use, by contrast, resist warping and maintain structural integrity over years of use.

Another key difference: alumina’s non-reactive surface won’t leach metals or alter food flavor—critical for acidic dishes like tomato-based casseroles. This makes alumina ceramic bowl plates and alumina ceramic plate bowls safer for daily use than glazed alternatives that may contain lead or cadmium.

Design-wise, brands like Staub have begun incorporating high-alumina formulations into premium lines, leading to products such as the alumina baking dish staub—a hybrid of European craftsmanship and advanced materials science.

5. Beyond Baking: Other Alumina Ceramic Kitchen Items

The utility of alumina extends beyond the oven. Consider these complementary pieces:

- Alumina ceramic sugar dish and alumina ceramic butter dish: Keep dry and moist ingredients fresh with airtight lids.

- Alumina ceramic childrens plates: Durable enough to survive drops, yet smooth and non-toxic.

- Alumina handcrafted ceramic plates and alumina ceramic plates for painting: Popular among artisans for their smooth, consistent surface.

- Alumina blue white porcelain plates: Blend traditional aesthetics with modern material benefits.

Even niche items like alumina ceramic plates and bowls for microwave or freezer use benefit from the material’s stability across temperature extremes.

6. What to Look For When Buying

Not all ‘alumina’ labeled products contain high-purity aluminum oxide. Check for:

- Minimum 85% alumina content (higher = better thermal performance)

- Oven-safe certification up to at least 260°C (500°F)

- Glaze-free or food-safe glaze (to avoid hidden toxins)

- Reputable brands offering alumina ceramic serving dishes with consistent quality control

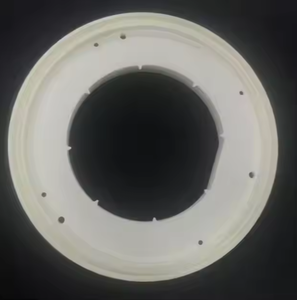

Avoid confusing alumina ceramic kitchenware with industrial alumina components like alumina discs, alumina ceramic tubes, or alumina crucibles—these serve entirely different purposes in engineering and manufacturing.

7. Conclusion

An alumina ceramic baking dish isn’t just another piece of cookware—it’s a long-term investment in safety, performance, and style. Whether you’re choosing an alumina oven dish ceramic for weeknight dinners or an alumina ceramic casserole for holiday feasts, the material’s resilience and purity make it a standout in today’s kitchen. As consumer demand for non-toxic, high-performance bakeware grows, alumina ceramic is poised to move from niche favorite to kitchen essential.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Choose. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.