Professional Premium Aluminum Oxide Products Supplier

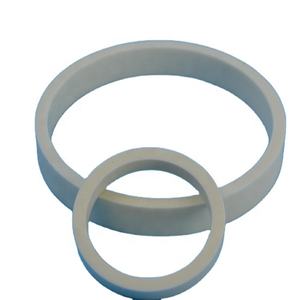

(Customized Size High Temperature Resistant 99% 96% 95% Al2o3 Alumina Ceramic Furnace Part Component Tiles Block Plate)

1. Why Customized Size High Temperature Resistant 99% 96% 95% Al2O3 Alumina Ceramic Furnace Part Component Tiles Block Plate Has Good Characteristics

1.1 Exceptional High-Temperature Resistance

Alumina ceramic (Al2O3) offers outstanding high-temperature resistance, making it ideal for furnace applications. The customizable size and varying purity levels (99%, 96%, 95%) allow for tailoring the material’s properties to specific thermal requirements. Higher purity grades, like 99% Al2O3, provide the best thermal stability and resistance to deformation at elevated temperatures. The ability to withstand extreme heat without degrading or losing structural integrity is a key advantage, ensuring long-term performance and reliability in demanding furnace environments. This inherent thermal stability minimizes the risk of component failure and downtime, enhancing overall operational efficiency.

1.2 Superior Chemical Inertness

Alumina ceramic exhibits excellent chemical inertness, resisting corrosion and chemical attack from harsh environments within furnaces. This characteristic is crucial when dealing with reactive gases or molten materials. The inert nature of Al2O3 prevents reactions that could weaken or degrade the ceramic, thereby prolonging its lifespan. Whether it’s a highly oxidizing or reducing atmosphere, alumina ceramics maintain their integrity. Customizable sizes ensure a precise fit within the furnace, further minimizing exposure and potential points of failure. This robust chemical resistance translates to lower maintenance costs and increased operational safety.

1.3 High Mechanical Strength and Wear Resistance

Alumina ceramic boasts high mechanical strength and exceptional wear resistance, essential for parts subjected to physical stress and abrasion within furnaces. The robust nature of Al2O3 ensures that components can withstand the mechanical loads associated with furnace operation, including thermal cycling and physical contact with other materials. Customizable size options allow for optimizing the structural design to maximize load-bearing capacity. This is particularly important for tiles, blocks, and plates that support heavy loads or are exposed to abrasive conditions. The combination of strength and wear resistance results in prolonged component life and reduced replacement frequency, contributing to cost savings and improved operational uptime.

2. What Is Customized Size High Temperature Resistant 99% 96% 95% Al2O3 Alumina Ceramic Furnace Part Component Tiles Block Plate

2.1 Definition and Composition

A customized size high-temperature resistant alumina ceramic part is a component specifically designed and manufactured to meet the unique dimensional and thermal requirements of a furnace. These parts are composed primarily of alumina (Al2O3), available in varying purity levels such as 99%, 96%, or 95%. The selection of purity level influences the material’s properties, with higher purity grades offering superior high-temperature performance, chemical resistance, and mechanical strength. These ceramic components are commonly produced as tiles, blocks, or plates, and are essential for lining furnace interiors, supporting heating elements, or serving as process-specific fixtures. The customization aspect ensures that the part perfectly fits the furnace geometry, optimizing its performance and lifespan.

2.2 Key Characteristics

The key characteristics of these alumina ceramic components include exceptional high-temperature resistance, enabling them to withstand extreme heat without deformation or degradation. They exhibit superior chemical inertness, resisting corrosion and chemical attack from aggressive furnace environments. The materials also possess high mechanical strength and wear resistance, crucial for parts subjected to physical stress and abrasion. Furthermore, the customizable size and shape allow for precise integration within the furnace, maximizing efficiency and performance. The varying purity levels (99%, 96%, 95% Al2O3) provide options to tailor the material properties to specific application requirements, balancing cost and performance effectively. These characteristics collectively contribute to the reliability and longevity of the furnace system.

2.3 Importance in Furnace Applications

Customized alumina ceramic components are vital in furnace applications due to their ability to withstand extreme operating conditions. Furnaces often operate at temperatures exceeding 1000°C, and alumina ceramics are capable of maintaining their structural integrity and performance at these levels. Their resistance to thermal shock minimizes the risk of cracking or failure during rapid temperature changes. Moreover, the chemical inertness of alumina prevents reactions with process materials, ensuring the purity of the final product. By providing a stable and reliable lining or structural element, these ceramic parts contribute significantly to the efficiency, safety, and longevity of the furnace. Custom sizes ensure optimal fit and performance, preventing hotspots and maximizing energy efficiency.

3. How Customized Size High Temperature Resistant 99% 96% 95% Al2O3 Alumina Ceramic Furnace Part Component Tiles Block Plate Was Produced?

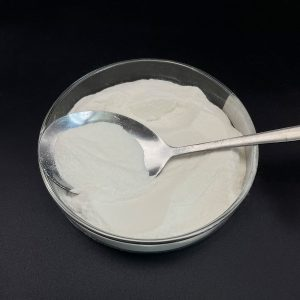

3.1 Material Selection and Preparation

The production of customized alumina ceramic parts begins with careful selection of the raw material. High-purity alumina powder (Al2O3) is chosen, with purity levels of 99%, 96%, or 95% depending on the desired properties of the final product. The alumina powder is then mixed with additives, such as binders and plasticizers, to improve its workability and green strength. Precise control of the mixing process ensures a homogenous mixture, which is essential for achieving uniform density and consistent properties in the finished ceramic part. The prepared mixture, often referred to as a “ceramic slurry” or “ceramic paste,” is then ready for shaping into the desired form. This initial step is critical for ensuring the quality and performance of the final alumina ceramic product.

3.2 Shaping and Forming Techniques

Various shaping and forming techniques are employed to create the desired size and shape of the alumina ceramic components. Common methods include dry pressing, isostatic pressing, slip casting, and extrusion. Dry pressing involves compacting the alumina powder mixture in a mold under high pressure. Isostatic pressing applies uniform pressure from all directions, resulting in higher density and improved homogeneity. Slip casting involves pouring a ceramic slurry into a porous mold, allowing water to be absorbed and leaving a solid ceramic layer. Extrusion forces the ceramic paste through a die to create long, continuous shapes that can be cut to the desired length. The choice of shaping method depends on the complexity of the component’s geometry, the required dimensional tolerances, and the desired production volume.

3.3 Sintering and Finishing

Following the shaping process, the “green” ceramic part undergoes sintering, a high-temperature heat treatment that densifies the material and strengthens the bonds between the alumina particles. Sintering is typically performed at temperatures between 1500°C and 1700°C in a controlled atmosphere. During sintering, the alumina particles fuse together, reducing porosity and increasing density, resulting in a strong and durable ceramic component. After sintering, the parts may undergo finishing processes such as grinding, lapping, or polishing to achieve the required dimensional accuracy and surface finish. Final inspection ensures that the parts meet the specified quality standards before being shipped to the customer. The sintering and finishing stages are critical for achieving the desired mechanical and thermal properties of the alumina ceramic parts.

4. What Are The Application Fields of Customized Size High Temperature Resistant 99% 96% 95% Al2O3 Alumina Ceramic Furnace Part Component Tiles Block Plate

4.1 Industrial Furnaces and Kilns

Customized alumina ceramic components are widely used in industrial furnaces and kilns across various industries. They serve as furnace linings, muffles, hearth tiles, and support structures due to their excellent high-temperature resistance, chemical inertness, and mechanical strength. In heat treatment furnaces, alumina tiles and blocks provide thermal insulation and protect the furnace structure from extreme temperatures. In ceramic kilns, alumina components support the firing of ceramic products, ensuring uniform heating and preventing contamination. The customizable sizes and shapes allow for precise integration within the furnace or kiln, optimizing performance and extending the lifespan of the equipment. Their ability to withstand harsh conditions makes them essential for efficient and reliable operation.

4.2 Semiconductor Manufacturing

In semiconductor manufacturing, customized alumina ceramic parts play a critical role in high-temperature processing equipment. Alumina is used in diffusion furnaces, annealing furnaces, and chemical vapor deposition (CVD) reactors due to its purity, thermal stability, and resistance to chemical attack. Alumina components serve as wafer carriers, susceptors, and insulators, providing a clean and stable environment for semiconductor processing. The customizable sizes and shapes allow for precise control of temperature gradients and gas flow within the processing chamber, ensuring uniform and high-quality film deposition or diffusion. The high purity of alumina minimizes the risk of contamination, which is crucial in semiconductor manufacturing where even trace impurities can affect device performance.

4.3 Thermal Processing of Metals

The thermal processing of metals, including sintering, annealing, and heat treatment, relies heavily on customized alumina ceramic components. Alumina is used to construct furnace linings, crucibles, and setters due to its ability to withstand high temperatures and corrosive environments. In sintering furnaces, alumina setters support metal powders during the consolidation process, preventing deformation and ensuring uniform shrinkage. In annealing furnaces, alumina linings provide thermal insulation and protect the furnace structure from oxidation and scaling. The chemical inertness of alumina prevents reactions with the metals being processed, maintaining their purity and integrity. Customizable sizes and shapes allow for optimized furnace design and efficient thermal processing of various metal alloys.

5. How To Choose A Good Customized Size High Temperature Resistant 99% 96% 95% Al2O3 Alumina Ceramic Furnace Part Component Tiles Block Plate

5.1 Consider the Operating Temperature

When selecting alumina ceramic components, the first consideration should be the operating temperature of the furnace or application. Alumina ceramics are available in varying purity levels (99%, 96%, 95%), and higher purity grades generally offer better high-temperature performance. Determine the maximum temperature the component will be exposed to and choose a purity level that exceeds this temperature rating. For applications exceeding 1600°C, 99% alumina is typically recommended. Ensure that the selected alumina grade maintains its mechanical strength and chemical resistance at the operating temperature to prevent deformation or degradation. Consulting with a materials engineer or ceramic supplier can provide valuable guidance in selecting the appropriate alumina grade for your specific temperature requirements.

5.2 Evaluate the Chemical Environment

The chemical environment within the furnace or application is another critical factor to consider. Alumina ceramics are generally chemically inert, but certain chemicals or gases can still react with the material at high temperatures. Identify the potential corrosive agents present in the environment and choose an alumina grade that is resistant to these chemicals. For example, if the environment contains strong acids or bases, a higher purity alumina grade may be necessary. Additionally, consider the atmosphere (oxidizing, reducing, or inert) and ensure that the alumina ceramic is stable under these conditions. Verify that the selected alumina grade will not react with the process materials or gases, which could lead to contamination or component failure. Consulting chemical compatibility charts or seeking expert advice can help determine the appropriate alumina grade for your specific chemical environment.

5.3 Assess Mechanical Stress and Wear

Assess the mechanical stress and wear conditions that the alumina ceramic component will be subjected to. Consider the load-bearing requirements, thermal cycling frequency, and potential for abrasion or impact. If the component will be supporting heavy loads or exposed to frequent thermal cycling, choose an alumina grade with high mechanical strength and thermal shock resistance. If abrasion or impact is a concern, select an alumina grade with high hardness and wear resistance. Customizable sizes and shapes can also play a role in optimizing the mechanical performance of the component. For example, thicker tiles or blocks may be necessary to withstand higher loads. Working with a ceramic manufacturer to design the component to withstand the specific mechanical stresses and wear conditions is crucial for ensuring its long-term reliability.

6. What Does People Also Ask About Customized Size High Temperature Resistant 99% 96% 95% Al2O3 Alumina Ceramic Furnace Part Component Tiles Block Plate

6.1 What is the difference between 99%, 96%, and 95% alumina ceramic?

The primary difference between 99%, 96%, and 95% alumina ceramic lies in their alumina (Al2O3) content and the corresponding impact on their properties. 99% alumina ceramic contains the highest purity, resulting in superior high-temperature performance, chemical resistance, and mechanical strength. It’s ideal for demanding applications requiring maximum thermal stability and minimal impurities. 96% alumina ceramic offers a balance between performance and cost, providing good high-temperature resistance and mechanical properties, making it suitable for a wide range of applications. 95% alumina ceramic has the lowest alumina content, offering a more cost-effective solution for less demanding applications where high-temperature performance and chemical resistance are not as critical. The choice depends on the specific requirements of the application and the desired trade-off between performance and cost.

6.2 How long do alumina ceramic furnace parts last?

The lifespan of alumina ceramic furnace parts depends on several factors, including the operating temperature, chemical environment, mechanical stress, and quality of the material. Under normal operating conditions, high-quality alumina ceramic parts can last for several years. However, extreme temperatures, corrosive environments, or high mechanical stress can significantly reduce their lifespan. Regular inspection and maintenance can help identify early signs of wear or degradation, allowing for timely replacement and preventing catastrophic failures. Following the manufacturer’s recommendations for operating conditions and maintenance procedures is crucial for maximizing the lifespan of alumina ceramic furnace parts. Proper handling and storage can also contribute to their longevity.

6.3 Can alumina ceramic furnace parts be repaired?

In general, alumina ceramic furnace parts are not easily repaired due to the brittle nature of the material and the high temperatures involved in their application. Minor cracks or chips may be repairable using specialized ceramic adhesives or fillers, but the repaired part may not have the same strength or performance as the original. Significant damage or failure typically requires replacement of the entire component. Attempting to repair severely damaged alumina ceramic parts can be risky, as the repaired part may fail unexpectedly, leading to further damage or safety hazards. Consulting with a ceramic expert or the manufacturer is recommended to assess the feasibility of repair and determine the best course of action.

Tags: Alumina Ceramic, High Temperature, Furnace Parts, Ceramic Tiles, Al2O3

(Customized Size High Temperature Resistant 99% 96% 95% Al2o3 Alumina Ceramic Furnace Part Component Tiles Block Plate)

Supplier

Alumina Technology Co., Ltd focus on the research and development, production and sales of aluminum oxide powder, aluminum oxide products, aluminum oxide crucible, etc., serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services. If you are looking for high quality Alumina Ceramic Products , please feel free to contact us. (nanotrun@yahoo.com)