Professional Premium Aluminum Oxide Products Supplier

1. Introduction

If you’ve ever searched for durable, heat-resistant, and elegant kitchenware, you’ve likely come across the term ‘alumina ceramic baking dish.’ But alumina ceramics go far beyond just baking—they’re used in everything from dinner plates and butter dishes to industrial tubes and crucibles. Thanks to their exceptional hardness, thermal stability, and chemical inertness, alumina-based ceramics are a top choice for both home chefs and engineers alike.

In this guide, we’ll walk you through what makes alumina ceramic dishes special, highlight popular types like the alumina ceramic casserole dish or alumina butter ceramic dish, and even touch on industrial-grade alumina components such as tubes, bricks, and bearings. Whether you’re outfitting your kitchen or sourcing materials for high-temp applications, there’s something here for everyone.

2. What Is Alumina Ceramic?

Alumina ceramic is made primarily from aluminum oxide (Al₂O₃), typically containing 90–99.9% purity. This material is sintered at extremely high temperatures, resulting in a dense, non-porous structure that resists heat, corrosion, and wear. Unlike traditional earthenware or stoneware, alumina ceramics maintain structural integrity even under intense thermal cycling—making them ideal for oven-to-table use.

Because of these properties, you’ll find alumina ceramic dishes for oven use labeled as ‘alumina oven ceramic dish’ or ‘alumina ceramic dishes for oven.’ They won’t crack under sudden temperature changes and are safe for broiling, baking, and even freezing.

3. Kitchen Uses: From Baking to Serving

Alumina ceramic baking dishes are prized not just for performance but also for their clean, modern look. The classic ‘alumina white ceramic plates’ offer a minimalist backdrop for any meal, while ‘alumina black ceramic plates’ or ‘alumina ceramic black plates’ add dramatic flair. Families love ‘alumina ceramic childrens plates’ for their chip resistance and non-toxic finish.

Beyond everyday dining, specialty items include:

- Alumina ceramic butter dish with lid (also called alumina butter dish ceramic with lid)

- Alumina ceramic sugar dish for elegant tabletop presentation

- Alumina salad ceramic bowl and alumina ceramic serving bowls for fresh, vibrant meals

- Alumina ceramic casserole with lid—perfect for slow-cooked dishes

- Alumina ramekin ceramic for individual desserts or soufflés

- Alumina ceramic Christmas plates and alumina Christmas ceramic platter for festive gatherings

Artists even use ‘alumina ceramic plates for painting’ thanks to their smooth, consistent surface. And brands like Staub sometimes incorporate alumina-enhanced glazes, leading to searches like ‘alumina baking dish staub.’

4. Industrial & Technical Applications

While kitchenware gets the spotlight, alumina’s real superpowers shine in industrial contexts. High-purity alumina is used to manufacture components that must endure extreme environments:

- Alumina ceramic tubes (including alumina thermocouple protection tubes and alumina high temperature ceramic tube) are essential in furnaces and sensors

- Alumina crucible and alumina ceramic crucible with lid can withstand temperatures over 1,700°C—ideal for melting metals like gold or steel

- Alumina bricks, such as alumina fire brick and alumina ceramic refractory bricks, line kilns and industrial ovens

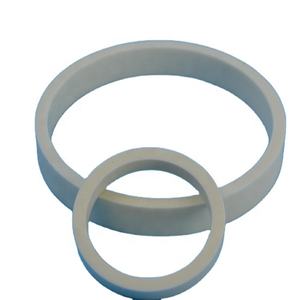

- Alumina ceramic balls and alumina zirconia balls serve as precision bearings in corrosive or high-speed settings

You’ll also find niche items like alumina ceramic disc taps, alumina grinding discs, and even alumina piezo ceramic disc used in electronics and fluid control systems.

5. Why Choose Alumina Over Other Ceramics?

Compared to standard porcelain or stoneware, alumina ceramic offers superior strength, lower porosity, and better thermal shock resistance. An ‘alumina ceramic plate bowls’ combo won’t absorb odors or stains, and ‘alumina handcrafted ceramic plates’ retain their luster after years of use.

For industrial users, the consistency and purity of alumina mean predictable performance under stress. Whether you need ‘alumina ceramic pipes’ for corrosive fluid handling or ‘alumina silicon carbide grinding disc for pottery,’ the material delivers reliability where others fail.

6. Care and Maintenance Tips

Despite their toughness, alumina ceramic items benefit from gentle care. Avoid sudden temperature swings (e.g., placing a hot dish directly on a cold countertop). Hand-washing is recommended for painted or decorative pieces like ‘alumina blue white porcelain plates’ to preserve designs.

Most alumina ceramic dinner plates and serving platters are dishwasher-safe, but always check manufacturer guidelines—especially for vintage or artisanal ‘alumina ceramic plates and bowls.’

7. Conclusion

From the kitchen to the lab, alumina ceramic proves its worth across countless applications. Whether you’re shopping for an ‘alumina ceramic baking dish’ to roast vegetables or sourcing ‘alumina ceramic tubes for sale’ for a high-temp project, this versatile material combines beauty, function, and resilience. As awareness grows, expect to see even more innovative uses of alumina—from smart home fixtures to aerospace components—solidifying its place as a modern ceramic cornerstone.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Discover. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.