Professional Premium Aluminum Oxide Products Supplier

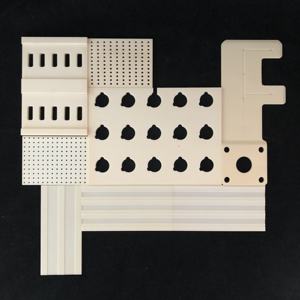

(Best Hardness Machinable Hot Pressed 99 Alumina Ceramic Block Al2o3 Brick)

1. Why Best Hardness Machinable Hot Pressed 99 Alumina Ceramic Block Al2O3 Brick Has Good Characteristics

1.1 Exceptional Material Density

The hot pressing manufacturing method creates alumina ceramic blocks with near-theoretical density (>99% of theoretical), eliminating porosity that weakens conventional ceramics. This dense microstructure directly translates to superior Vickers hardness (16-18 GPa) and exceptional wear resistance, making it ideal for abrasive environments. The absence of voids also enhances chemical inertness, preventing corrosive penetration even in aggressive chemical processing.

1.2 Optimized Mechanical Properties

Hot pressed 99% alumina achieves a unique balance between extreme hardness and controlled machinability. While maintaining impressive compressive strength (over 2,500 MPa), specialized formulations allow precision machining of complex geometries impossible with standard alumina. This combination stems from controlled grain growth during sintering and minimized impurity content, resulting in consistent mechanical performance across operating temperatures up to 1,600°C.

1.3 Thermal and Electrical Advantages

With thermal conductivity of 30 W/mK and low thermal expansion coefficient (8.5×10⁻⁶/K), these blocks withstand severe thermal cycling without cracking. The high purity alumina composition delivers excellent electrical insulation (10¹⁴-10¹⁵ Ω·cm volume resistivity), crucial for semiconductor processing equipment. These properties ensure dimensional stability in high-temperature applications like furnace linings and plasma containment, as demonstrated in high-temperature laboratory sample preparation environments.

2. What Is Best Hardness Machinable Hot Pressed 99 Alumina Ceramic Block Al2O3 Brick

2.1 Material Composition

This advanced technical ceramic comprises 99% minimum aluminum oxide (Al₂O₃) with precisely controlled sintering additives (typically MgO or SiO₂). The “99 alumina” designation indicates superior purity compared to standard 95% grades, directly enhancing mechanical and thermal properties. The material’s crystalline structure features fine, uniform α-alumina grains (1-5μm) with strong intergranular bonding, achieved through optimized hot pressing parameters.

2.2 Key Property Specifications

Characterized by density ≥3.92 g/cm³, flexural strength >400 MPa, and Rockwell hardness HRA 88-90, this material outperforms most engineering ceramics. Unlike traditional alumina, specialized formulations maintain machinability in pre-sintered states while achieving final hardness post-firing. This enables fabrication of complex components like precision valves or custom laboratory baking dishes with tight dimensional tolerances (±0.1%).

3. How Best Hardness Machinable Hot Pressed 99 Alumina Ceramic Block Al2O3 Brick Was Produced?

3.1 Powder Processing and Forming

Production begins with high-purity α-alumina powder milled to submicron particle sizes. Organic binders and sintering aids are introduced through colloidal processing for uniform distribution. The mixture is pre-formed using cold isostatic pressing (CIP) at 100-200 MPa, creating “green” blocks with sufficient strength for machining operations. This stage allows cost-effective shaping of complex geometries before final densification.

3.2 Hot Pressing Sintering

Machined green bodies undergo hot pressing in graphite dies at 1,400-1,600°C under simultaneous uniaxial pressure (10-40 MPa). This dual-action process achieves full densification in 1-4 hours, significantly faster than pressureless sintering. The applied pressure suppresses pore formation and limits grain growth, creating the fine-grained microstructure responsible for the material’s exceptional hardness and strength. Controlled cooling prevents thermal stress cracking.

4. What Are The Application Fields of Best Hardness Machinable Hot Pressed 99 Alumina Ceramic Block Al2O3 Brick

4.1 Industrial Wear Components

In mining and mineral processing, these blocks serve as abrasion-resistant liners for chutes, cyclones, and pump housings, outperforming steel in slurry transport applications. The material’s combination of hardness and impact resistance makes it ideal for shot blast nozzles, sandblasting injectors, and valve seats in high-pressure systems, extending component lifespan 3-5× over conventional materials.

4.2 High-Temperature Systems

The ceramic’s thermal stability enables use in furnace hearth plates, kiln furniture, and thermocouple protection tubes in environments exceeding 1,500°C. Semiconductor manufacturers utilize these blocks for diffusion furnace components and wafer handling paddles where metallic contamination must be avoided. Its electrical insulation properties suit plasma etching electrodes and ion implant fixtures.

4.3 Precision Laboratory Equipment

In research settings, the material facilitates high-temperature sample preparation as crucibles, combustion boats, and specialized alumina ceramic baking dishes that maintain integrity during repeated thermal cycling. Its chemical inertness allows safe processing of aggressive reagents, while machinability supports custom instrument components requiring dimensional stability at temperature extremes.

5. How To Choose A Good Best Hardness Machinable Hot Pressed 99 Alumina Ceramic Block Al2O3 Brick

5.1 Material Certification

Verify material certifications including ISO 6474-1 compliance and mill test reports confirming alumina content ≥99%, density ≥3.92 g/cm³, and flexural strength >400 MPa. Reputable suppliers provide microstructural analysis showing grain size distribution below 5μm. For critical applications, request ASTM C1161 mechanical test data and thermal shock resistance validation.

5.2 Manufacturing Quality Indicators

Inspect surfaces for machining marks consistent with diamond tool processing – irregular patterns may indicate improper sintering. Check dimensional tolerances using precision gauges; high-quality blocks maintain ±0.1% tolerance on critical dimensions. Assess edge integrity; chipping suggests either machining defects or sintering problems. Request documentation of furnace temperature profiles during hot pressing.

6. What Does People Also Ask About Best Hardness Machinable Hot Pressed 99 Alumina Ceramic Block Al2O3 Brick

6.1 Common Technical Questions

Q: How does hot pressing differ from regular sintering?

A: Hot pressing applies simultaneous heat and pressure, achieving full density at lower temperatures with finer grain structure than conventional sintering.

Q: Can this ceramic withstand thermal shock?

A: Yes, its low thermal expansion coefficient provides excellent thermal shock resistance – typically surviving ΔT >200°C water quench tests.

Q: What machining methods are compatible?

A: Diamond grinding, laser cutting, and ultrasonic machining are effective. “Green state” machining before final sintering reduces processing costs.

Q: How does purity affect performance?

A: 99% alumina exhibits 30% higher thermal conductivity and superior corrosion resistance compared to 95% grades, justifying premium pricing for critical applications.

Tags: 99% alumina ceramic, Al2O3 brick, hot pressed alumina, machinable ceramic block, high hardness alumina, industrial ceramic, laboratory ceramic, alumina ceramic block

(Best Hardness Machinable Hot Pressed 99 Alumina Ceramic Block Al2o3 Brick)

Supplier

Alumina Technology Co., Ltd focus on the research and development, production and sales of aluminum oxide powder, aluminum oxide products, aluminum oxide crucible, etc., serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services.