Professional Premium Aluminum Oxide Products Supplier

(High Precision 99% Al2O3 Alumina Ceramic Block High Temperature Resistant for Industrial Ceramic Applications)

1. Why High Precision 99% Al2O3 Alumina Ceramic Block Excels in Industrial Applications

1.1 Exceptional Material Properties

High-precision 99% Al₂O₃ alumina ceramic blocks deliver superior performance due to their inherent material characteristics. The 99% alumina composition provides outstanding hardness (Rockwell H 80-90), wear resistance, and compressive strength exceeding 2,000 MPa. These ceramics maintain dimensional stability at temperatures up to 1,750°C, far outperforming metals and polymers. Their ionic molecular structure creates exceptional electrical insulation (1014-1015 Ω·cm) and chemical inertness, resisting acids, alkalis, and corrosive gases. This combination enables reliability in extreme industrial environments where thermal shock, abrasion, or chemical exposure would degrade conventional materials.

1.2 Precision Engineering Advantages

The high-precision manufacturing of these blocks ensures micron-level tolerances (±0.1%) and ultra-smooth surface finishes (Ra ≤ 0.4μm). This dimensional accuracy is critical for applications like semiconductor wafer handling, laser alignment components, and precision metrology fixtures. Unlike metals, alumina ceramics exhibit negligible thermal expansion (8.1×10-6/K), preventing deformation during rapid temperature cycling. Their non-porous structure (<1% water absorption) eliminates contamination risks in cleanroom or vacuum environments. These characteristics make them indispensable for applications demanding both thermal resilience and geometric precision, as highlighted in industrial alumina solutions for high-temperature lab crucibles.

2. Defining High Precision 99% Al₂O₃ Alumina Ceramic Blocks

2.1 Composition and Specifications

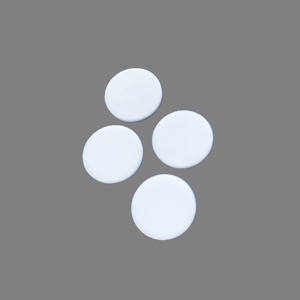

High-precision 99% Al₂O₃ alumina ceramic blocks consist of 99% pure aluminum oxide (Al₂O₃) with trace additives like MgO or SiO₂ for sintering enhancement. These technical ceramics are characterized by density ≥3.9 g/cm³, flexural strength >350 MPa, and dielectric strength >15 kV/mm. Unlike standard alumina ceramics (85-95% purity), the 99% grade offers superior thermal conductivity (30 W/mK) and reduced dielectric loss. The “high-precision” designation indicates advanced processing techniques that achieve dimensional accuracies within 5μm and surface roughness below 0.8μm. These blocks are manufactured in standardized and custom geometries, including plates, rods, tubes, and complex machined components.

2.2 Material Science Fundamentals

The exceptional properties stem from alumina’s hexagonal crystal lattice structure, which forms strong covalent bonds during sintering. At 99% purity, the minimized glassy phase between crystalline grains enhances mechanical and thermal performance. Unlike lower-grade aluminas, this composition prevents grain boundary weakening at elevated temperatures, maintaining structural integrity beyond 1,600°C. The material’s performance characteristics align with industrial requirements discussed in high-temperature applications, though engineered for more extreme industrial environments.

3. Manufacturing Process of High-Precision Alumina Ceramic Blocks

3.1 Advanced Forming Techniques

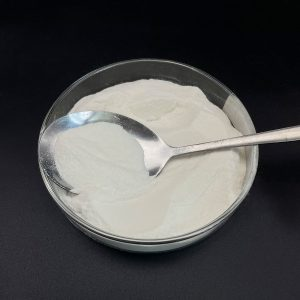

Production begins with spray-dried 99% pure Al₂O₃ powder blended with organic binders. Precision forming employs advanced methods like isostatic pressing (300+ MPa pressure) or injection molding to achieve near-net shapes with minimal porosity. For complex geometries, CNC-machined green bodies are created before sintering. Critical to dimensional control is the pre-sintering “bisque” stage at 1,100-1,300°C, which enables precision diamond grinding to tolerances ≤10μm. This stage removes binder materials while establishing preliminary structural integrity without full densification.

3.2 High-Temperature Sintering

Final sintering occurs in high-temperature kilns (1,600-1,800°C) using precisely controlled heating profiles. Temperature ramps are carefully managed at 1-5°C/minute to prevent warping and ensure uniform densification. During the 12-48 hour sintering cycle, alumina particles undergo diffusion bonding, shrinking by 15-20% volumetrically while achieving >99% theoretical density. Post-sintering, components undergo precision diamond grinding, lapping, or laser machining to achieve sub-micron surface finishes and tolerances within ±0.01mm. This meticulous process creates the thermal stability and dimensional accuracy essential for industrial applications, similar to those in specialized alumina components.

4. Industrial Application Fields

4.1 High-Temperature Processing Systems

Alumina ceramic blocks serve as essential components in furnace linings, kiln furniture, and heat treatment fixtures where temperatures exceed 1,500°C. Their thermal stability prevents deformation in semiconductor diffusion furnaces and metal annealing systems. In chemical processing, they function as catalyst supports, reactor liners, and thermocouple protection tubes resistant to corrosive media. The electrical insulation properties make them ideal for high-voltage insulators in power transmission and plasma chamber components in thin-film deposition systems.

4.2 Precision Engineering Applications

These ceramics are critical in semiconductor manufacturing as wafer chucks, plasma etch components, and lithography stages requiring sub-micron flatness. In laser systems, they serve as mirror mounts and beam delivery components due to minimal thermal expansion. Industrial automation utilizes them for wear-resistant guide rails, bearing components, and metrology equipment. Medical technology applications include MRI components and surgical instrument guides. The versatility of alumina ceramics across sectors is evident from multi-industry alumina solutions.

5. Selection Criteria for Industrial-Grade Alumina Blocks

5.1 Performance Parameter Evaluation

Selecting optimal alumina blocks requires verifying material certifications including purity (≥99%), density (≥3.89 g/cm³), and porosity (<0.1%). Critical mechanical specifications include flexural strength (>380 MPa), hardness (>Hv 1500), and fracture toughness (4 MPa·m½). For thermal applications, confirm maximum service temperature (1,650°C), thermal conductivity (30-35 W/mK), and thermal shock resistance (ΔT > 300°C). Surface finish requirements should align with application needs – Ra ≤ 0.4μm for sealing surfaces versus Ra ≤ 1.6μm for structural components.

5.2 Manufacturing Quality Assessment

Evaluate suppliers based on sintering capabilities (temperature uniformity within ±5°C), precision machining equipment (ultrasonic/diamond grinding), and metrology certifications (ISO 17025). Require documentation of dimensional tolerances, typically ±0.1% or ±0.05mm. Validate quality through material test reports for key properties and statistical process control data. For critical applications, request component-level testing including helium leak detection (<1×10-9 mbar·L/s) and surface resistivity verification (>1014 Ω).

6. Frequently Asked Questions

6.1 Thermal and Mechanical Performance

Q: How does 99% alumina compare to 95% grade in thermal applications?

A: The 99% grade offers 20% higher thermal conductivity (30 vs 25 W/mK), 15% better thermal shock resistance, and 100°C higher maximum service temperature. The reduced glass phase minimizes creep deformation at sustained high temperatures.

Q: What is the typical service life in abrasive environments?

A: Under moderate abrasive conditions, alumina blocks typically last 5-8 times longer than tool steel. Actual lifespan depends on particulate hardness, impact velocity, and loading – consult wear resistance testing data for specific applications.

6.2 Machining and Compatibility

Q: Can these blocks be machined post-sintering?

A: Yes, specialized diamond grinding achieves tolerances to ±0.005mm. Ultrasonic machining creates complex features, while laser drilling produces micro-holes down to 0.1mm diameter. Post-machining stress relief annealing is recommended for critical applications.

Q: Are they compatible with vacuum and ultra-clean environments?

A: Yes, their non-porous structure and minimal outgassing (<10-9 torr·L/s/cm²) meet SEMI F20 and NASA outgassing standards. Surface treatments can achieve particle counts <5/ft² for Class 10 cleanrooms.

Tags: alumina ceramic block, 99% Al2O3 ceramic, high temperature ceramic, industrial alumina, precision ceramic components, alumina machining, ceramic insulators, high-purity alumina

(High Precision 99% Al2O3 Alumina Ceramic Block High Temperature Resistant for Industrial Ceramic Applications)

Supplier

Alumina Technology Co., Ltd focus on the research and development, production and sales of aluminum oxide powder, aluminum oxide products, aluminum oxide crucible, etc., serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services.