Professional Premium Aluminum Oxide Products Supplier

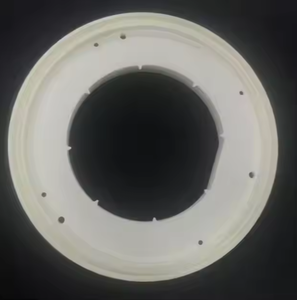

(High Purity Alumina Ceramic Block Industrial Grade 99 Al2O3 Ceramic Part)

1. Why High Purity Alumina Ceramic Block Industrial Grade 99 Al2O3 Ceramic Part Has Good Characteristics

Industrial Grade 99 Al₂O₃ ceramic blocks exhibit exceptional properties due to their 99% purity aluminum oxide composition. The high purity minimizes impurities like silica and iron oxide, enhancing mechanical strength (up to 400 MPa) and wear resistance. These ceramics maintain structural integrity at temperatures exceeding 1600°C while resisting thermal shock, making them ideal for extreme environments. Their dense microstructure provides excellent chemical inertness, preventing corrosion from acids and alkalis. The material’s dielectric strength (15-20 kV/mm) suits electrical insulation applications. These combined properties – validated in applications from semiconductor manufacturing to thermal processing – create a versatile material solution for industrial challenges. For insights on thermal performance in similar alumina ceramics, see high-temperature industrial applications.

2. What Is High Purity Alumina Ceramic Block Industrial Grade 99 Al2O3 Ceramic Part

Industrial Grade 99 Al₂O₃ ceramic blocks are precision-engineered components composed of 99% aluminum oxide with trace binders. Unlike standard ceramics, this grade undergoes rigorous processing to achieve porosity below 1% and density exceeding 3.9 g/cm³. These blocks typically feature dimensional tolerances within ±0.1% and surface finishes down to Ra 0.2μm. The microstructure consists of uniform α-alumina crystals bonded through solid-state sintering, creating isotropic properties. Available in custom geometries – from simple tiles to complex multi-axis machined forms – they serve as wear plates, insulators, or reactor linings. Their exceptional hardness (9 Mohs) and compressive strength (2,500 MPa) differentiate them from lower-purity (85-95% Al₂O₃) alternatives. For comprehensive material insights, refer to alumina ceramic performance characteristics.

3. How High Purity Alumina Ceramic Block Industrial Grade 99 Al2O3 Ceramic Part Was Produced?

Production involves four critical phases: powder processing, forming, sintering, and finishing. High-purity α-alumina powder undergoes ball milling with sintering aids like MgO to achieve submicron particle size distribution. Forming methods include:

3.1 Dry Pressing

Uniaxial/isostatic pressing at 100-200 MPa creates near-net shapes with minimal binder content.

3.2 Sintering

Components fire in tunnel kilns at 1600-1800°C for 24-48 hours, achieving >99% theoretical density.

3.3 Precision Machining

Diamond grinding post-sintering achieves micron-level tolerances. Quality verification includes ultrasonic flaw detection and metallographic analysis to ensure microstructure consistency. This controlled process prevents defects like common alumina ceramic issues such as microcracking or density variations.

4. What Are The Application Fields of High Purity Alumina Ceramic Block Industrial Grade 99 Al2O3 Ceramic Part

These ceramic blocks serve critical functions across industries due to their extreme durability:

4.1 Semiconductor Manufacturing

Wafer processing fixtures, plasma-resistant components

4.2 Metallurgy

Thermocouple protection tubes, furnace linings

4.3 Chemical Processing

Reactor liners, pump seals in corrosive environments

4.4 Energy Sector

Insulators in high-voltage systems, fuel cell components

Additional applications include precision measurement equipment, ballistic armor, and medical implant coatings. Their non-contaminating properties make them essential in pharmaceutical processing. The material’s versatility in high-performance applications extends from laboratory to heavy industrial settings.

5. How To Choose A Good High Purity Alumina Ceramic Block Industrial Grade 99 Al2O3 Ceramic Part

Selection requires evaluating five key parameters:

5.1 Material Certification

Verify purity (≥99%) through XRF reports and density (>3.89 g/cm³)

5.2 Mechanical Properties

Confirm flexural strength (>380 MPa) and fracture toughness (≥4 MPa·m½)

5.3 Geometric Precision

Require dimensional tolerance certifications (±0.05mm for critical dimensions)

5.4 Surface Integrity

Inspect for microcracks using dye-penetrant testing

5.5 Manufacturer Capabilities

Select suppliers with ISO 9001 certification and in-house metallurgical labs. Avoid suppliers unable to provide material test certificates or with inconsistent sintering practices that cause common alumina defects. Request samples for thermal cycling tests before bulk procurement.

6. What Does People Also Ask About High Purity Alumina Ceramic Block Industrial Grade 99 Al2O3 Ceramic Part

6.1 What temperature limits apply to Grade 99 alumina blocks?

Long-term operational limit is 1650°C in oxidizing atmospheres, with short peaks to 1750°C possible. Thermal shock resistance depends on wall thickness – thinner sections withstand ΔT >500°C.

6.2 How does purity affect performance versus 95% alumina?

99% grade exhibits 30% higher wear resistance, 2x dielectric strength, and superior chemical stability due to reduced glass phase content at grain boundaries.

6.3 Can these blocks be machined post-sintering?

Yes, using diamond-embedded tools. However, complex features should be green-machined before sintering to reduce costs.

6.4 What joining methods are recommended?

Diffusion bonding or specialized glass frits are preferred. Avoid adhesives for high-temperature applications. For more on material limitations, see common alumina ceramic challenges.

Tags: alumina ceramic block, industrial alumina, 99% Al2O3, high purity ceramic, alumina components, technical ceramics, industrial ceramics, alumina wear parts

(High Purity Alumina Ceramic Block Industrial Grade 99 Al2O3 Ceramic Part)

Supplier

Alumina Technology Co., Ltd focus on the research and development, production and sales of aluminum oxide powder, aluminum oxide products, aluminum oxide crucible, etc., serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services.