Professional Premium Aluminum Oxide Products Supplier

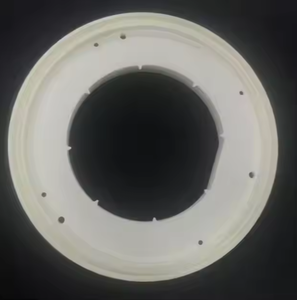

(Aluminum Oxide Ceramic Board Polished 99.7% Alumina Ceramic Sheet Al2O3 Plate Ceramic Block)

The Comprehensive Guide to Aluminum Oxide Ceramic Board: Properties, Production, and Applications

1. Why 99.7% Alumina Ceramic Boards Exhibit Superior Characteristics

Aluminum oxide ceramic boards with 99.7% purity demonstrate exceptional properties due to their near-perfect crystalline structure. The high alumina concentration creates strong ionic bonds that deliver extreme hardness (9 on Mohs scale), making them resistant to abrasive wear. Their dense microstructure provides outstanding thermal stability, maintaining integrity at temperatures up to 1650°C while exhibiting minimal thermal expansion. This purity level also enables excellent chemical inertness, resisting corrosion from strong acids and alkalis. The polished surface achieves exceptional flatness (typically <0.5μm Ra), crucial for precision applications. These characteristics stem from the material’s inherent dielectric strength (15-20 kV/mm), low loss tangent at high frequencies, and biocompatibility – properties that make alumina ceramics indispensable across demanding technical fields.

2. Understanding Aluminum Oxide Ceramic Board Composition

Aluminum oxide ceramic board (Al₂O₃ plate) is an advanced technical ceramic composed of 99.7% pure aluminum oxide crystals with trace sintering additives. This high-purity alumina ceramic differs fundamentally from standard ceramics through its engineered microstructure, featuring sub-micron grain boundaries that enhance mechanical properties. The material exists in various forms: industrial ceramic boards (typically 1-100mm thickness), precision ceramic sheets (0.1-1mm), and specialized ceramic blocks for structural applications. Polished variants undergo precision surface grinding to achieve optical-grade flatness with surface roughness below 0.1μm. Unlike common ceramics, these engineered alumina products exhibit consistent isotropic properties due to controlled crystallization during sintering. Their characteristic white appearance and exceptional density (>3.89 g/cm³) visually distinguish them from lower-grade alumina ceramics.

3. Manufacturing Process of High-Purity Alumina Ceramic Boards

The production of 99.7% alumina ceramic boards involves precision-controlled phases:

3.1 Powder Processing and Forming

High-purity α-alumina powder undergoes colloidal processing to eliminate impurities before spray drying. The micronized powder is then formed into boards using either:

– Dry Pressing: For thicknesses up to 20mm with automated hydraulic presses

– Isostatic Pressing: For thicker blocks (up to 100mm) using uniform hydrostatic pressure

– Tape Casting: For thin sheets (0.1-1mm) requiring dimensional precision

3.2 Sintering and Finishing

Green bodies undergo high-temperature sintering at 1600-1800°C in tunnel kilns, where controlled heating rates prevent deformation. The sintering process achieves near-theoretical density through grain boundary diffusion. Post-sintering, precision diamond grinding achieves tight tolerances (±0.01mm), followed by multi-stage polishing with progressively finer diamond abrasives. Final quality verification includes flatness testing, dielectric strength measurement, and microstructural analysis to ensure absence of voids or impurities that compromise performance.

4. Technical Applications of Polished Alumina Ceramic Boards

99.7% alumina ceramic boards serve critical functions across industries due to their unique properties:

4.1 Electronics and Semiconductor

As vacuum-compatible insulating substrates for power electronics, RF windows, and wafer processing fixtures. Their thermal conductivity (28-35 W/mK) efficiently dissipates heat while maintaining electrical isolation.

4.2 Industrial Processing

Used as wear-resistant liners in material handling systems, precision gauging surfaces in metrology, and thermally stable platens in hot pressing equipment. Their chemical inertness makes them ideal for reaction chambers in semiconductor manufacturing.

4.3 Specialized Components

In medical technology for radiation therapy positioning systems, and in research settings as particle accelerator components. The material’s versatility extends to consumer applications like high-performance baking dishes where thermal shock resistance is critical, demonstrating how industrial material properties translate to consumer benefits such as even heat distribution and durability.

5. Selection Criteria for High-Performance Alumina Ceramic Boards

Choosing optimal alumina ceramic boards requires technical evaluation:

5.1 Material Specifications

Verify purity (99.7% vs. lower grades), density (>3.89 g/cm³), and surface finish (specify Ra value). Request material test certificates for flexural strength (>400 MPa) and dielectric strength. Crucially, examine microstructural reports for uniform grain size distribution (typically 3-5μm).

5.2 Performance Validation

Assess thermal shock resistance through standardized testing (e.g., DIN 51122). Confirm flatness tolerances with optical interferometry reports. For electrical applications, validate volume resistivity (>10¹⁴ Ω·cm) and dielectric constant (9-10 at 1 MHz). Review manufacturer’s quality certifications (ISO 9001, AS9100) and material traceability systems.

6. Frequently Asked Questions About Alumina Ceramic Boards

6.1 How does surface finish affect performance?

Polished surfaces (Ra <0.1μm) reduce friction, prevent particle generation in cleanrooms, and enhance sealing capability. The polishing process also eliminates microcracks that could compromise mechanical strength.

6.2 Can alumina ceramic withstand thermal cycling?

Properly manufactured 99.7% alumina survives repeated thermal cycling from -50°C to 1500°C due to controlled thermal expansion (8.5×10⁻⁶/K) and high fracture toughness. Discover more about thermal performance in this detailed analysis.

6.3 What cleaning methods are appropriate?

Ultrasonic cleaning with non-ionic solutions is recommended. Avoid halogen acids which can etch surfaces. For kitchen applications, see care guidelines.

6.4 How does alumina compare to aluminum nitride?

While aluminum nitride offers higher thermal conductivity (150-180 W/mK), alumina provides superior cost efficiency, mechanical strength, and dielectric properties. Alumina remains preferred for structural components and electrical insulation.

Tags: alumina ceramic board, 99.7% alumina plate, Al2O3 ceramic sheet, polished ceramic block, high purity alumina, industrial ceramic substrate, technical ceramic plate, alumina ceramic applications

(Aluminum Oxide Ceramic Board Polished 99.7% Alumina Ceramic Sheet Al2O3 Plate Ceramic Block)

Supplier

Alumina Technology Co., Ltd focus on the research and development, production and sales of aluminum oxide powder, aluminum oxide products, aluminum oxide crucible, etc., serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services.