Professional Premium Aluminum Oxide Products Supplier

(High Temperature 99% 99.5% Al2o3 Alumina Ceramic Block Blank Brick)

1. Why High Temperature 99% 99.5% Al2O3 Alumina Ceramic Block Blank Brick Has Good Characteristics

1.1 Exceptional Material Properties

High-purity alumina ceramics derive their superior performance from inherent material properties. With Al2O3 content exceeding 99%, these bricks exhibit exceptional thermal stability up to 1750°C due to strong ionic/covalent atomic bonding. The crystalline corundum structure delivers remarkable mechanical strength (Vickers hardness ~1600 HV) and fracture toughness, resisting thermal shock through low thermal expansion coefficients (8.1×10-6/K). Chemical inertness prevents corrosion from molten metals, acids, and alkalis, while near-zero porosity (<1%) minimizes gas permeability. These characteristics stem from controlled sintering processes that achieve >98% theoretical density, creating homogeneous microstructures ideal for extreme environments. The 99.5% grade offers marginally enhanced properties for ultra-demanding applications where marginal purity gains impact performance longevity.

2. What Is High Temperature 99% 99.5% Al2O3 Alumina Ceramic Block Blank Brick

2.1 Composition and Structural Definition

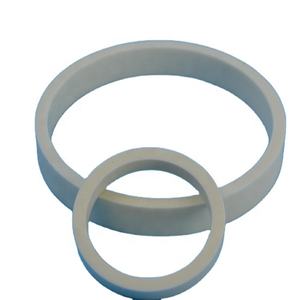

High-temperature alumina ceramic blocks are precision-engineered refractory components composed of ≥99% α-alumina (Al2O3) crystals. These dense, polycrystalline structures form through high-pressure molding and sintering at 1600-1800°C. “Blank brick” denotes unprocessed rectangular units before machining into final components. Unlike traditional firebricks, these ultra-high-purity ceramics contain minimal silica or fluxing agents, maximizing refractoriness. Typical dimensions range from 10x10x30mm standard blocks to large 300x150x75mm bricks, with custom geometries achievable through diamond grinding. The 99.5% variant features stricter impurity controls (<0.1% SiO2+Fe2O3+Na2O), yielding superior dielectric strength and wear resistance for specialized applications where performance margins are critical.

3. How High Temperature 99% 99.5% Al2O3 Alumina Ceramic Block Blank Brick Was Produced?

3.1 Precision Manufacturing Process

Production begins with high-purity alumina powder (D50 = 0.5-1μm) synthesized through calcination or hydrolysis. Powder undergoes spray drying with organic binders to enhance flowability before isostatic pressing at 100-300MPa, forming green bodies with uniform density. Pre-sintering at 1100°C removes binders, followed by final sintering in tunnel kilns at 1600-1800°C for 10-48 hours. Critical temperature ramping rates (1-5°C/minute) prevent cracking while achieving >98% theoretical density. Factory production implements strict controls: laser particle analyzers monitor raw materials, and CMMs verify dimensional tolerances within ±0.5%. Post-production, blanks undergo ultrasonic testing for microcracks before diamond grinding achieves final surface finishes (Ra ≤ 0.4μm) for precision applications.

4. What Are The Application Fields of High Temperature 99% 99.5% Al2O3 Alumina Ceramic Block Blank Brick

4.1 Industrial Implementation Scenarios

These refractory bricks serve critical functions across high-temperature industries. In metallurgy, they line induction furnaces and crucibles for melting non-ferrous alloys. Semiconductor manufacturing utilizes them as diffusion furnace liners and wafer-processing components where ultra-low contamination is essential. Energy sectors deploy them in ceramic kilns and glass tank regenerators, withstanding continuous operation at 1500-1650°C. Chemical processing plants employ them as reactor linings for corrosive syntheses. Additional applications include:

– Thermal barrier systems in aerospace test rigs

– Sintering setters for technical ceramics

– Incinerator combustion chambers

– High-voltage insulation in plasma generators

– Wear-resistant chutes in mineral processing

The 99.5% grade is specified for semiconductor diffusion processes where ionic contamination must be minimized, while 99% suffices for most industrial furnace applications.

5. How To Choose A Good High Temperature 99% 99.5% Al2O3 Alumina Ceramic Block Blank Brick

5.1 Selection Criteria and Verification

Prioritize certified alumina content (99% vs 99.5%) via supplier material test reports. Verify bulk density (>3.8 g/cm³) and porosity (<0.5%) through mercury porosimetry tests. For thermal cycling applications, confirm thermal shock resistance via standardized quenching tests (e.g., DIN 51068). Inspect dimensional tolerances – premium blanks maintain ±0.1% dimensional stability post-sintering. Cross-reference manufacturer certifications (ISO 9001, ISO 14001) and request samples for:

– XRD analysis verifying α-phase crystallization

– SEM imaging assessing microstructural homogeneity

– 4-point bend testing (minimum 300MPa modulus of rupture)

– Coefficient of thermal expansion validation (RT-1000°C)

For corrosive environments, request acid/alkali resistance data. Reputable suppliers provide traceable lot documentation and customized machining capabilities for complex geometries.

6. What Does People Also Ask About High Temperature 99% 99.5% Al2O3 Alumina Ceramic Block Blank Brick

6.1 Technical FAQs

Q: What maximum continuous service temperature can these bricks withstand?

A: 99% grade withstands 1650°C in oxidizing atmospheres; 99.5% grade achieves 1750°C with appropriate structural support.

Q: How do 99% and 99.5% grades differ functionally?

A: The 99.5% variant offers 10-15% higher creep resistance, 20% better dielectric strength, and marginally lower high-temperature deformation, making it essential for semiconductor and advanced research applications.

Q: Can these bricks be machined post-sintering?

A: Yes, diamond grinding achieves precision tolerances (±0.05mm). However, avoid sharp internal angles below 1.5mm radius to prevent stress fractures.

Q: What maintenance extends service life?

A: Implement thermal cycling protocols (max 150°C/hour ramp rates), use compatible mortar systems, and conduct regular ceramic surface inspections for microcrack detection. Avoid thermal shocks exceeding 300°C differentials.

Tags: alumina ceramic block, alumina brick, high temperature refractory, 99% alumina, 99.5% alumina, Al2O3 ceramic, alumina blank brick, ceramic block, alumina refractory brick, high purity alumina

(High Temperature 99% 99.5% Al2o3 Alumina Ceramic Block Blank Brick)

Supplier

Alumina Technology Co., Ltd focus on the research and development, production and sales of aluminum oxide powder, aluminum oxide products, aluminum oxide crucible, etc., serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services.