Professional Premium Aluminum Oxide Products Supplier

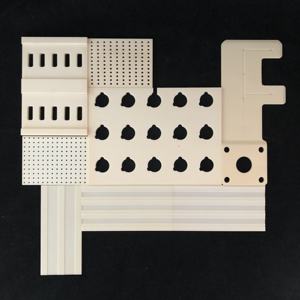

(High Temperature Resistance 99% Al2o3 Ceramic Block Plate Alumina Board/Brick/Tile With Holes)

1. Why High Temperature Resistance 99% Al2O3 Ceramic Block Plate Alumina Board/Brick/Tile With Holes Has Good Characteristics

1.1 Exceptional Material Properties

99% alumina ceramics derive their superior performance from inherent material characteristics. The high purity aluminum oxide composition creates an exceptionally stable crystalline structure that maintains integrity up to 1750°C. This elevated temperature resistance stems from strong ionic bonds between aluminum and oxygen atoms, requiring substantial energy to disrupt. The material’s low thermal expansion coefficient (8.1×10-6/K) prevents thermal shock fractures during rapid temperature cycling, while its high thermal conductivity (30 W/mK) enables efficient heat distribution across components.

1.2 Structural Advantages of Perforated Design

The precisely engineered holes in these alumina components enhance functionality without compromising structural integrity. Perforations reduce thermal mass, enabling faster heating/cooling rates while maintaining uniform temperature distribution. Strategically placed holes facilitate mechanical fastening, gas flow management, and weight reduction in high-temperature systems. The 99% purity alumina ensures minimal porosity (≤0.8%), preventing gas permeation through walls while allowing controlled passage through designed apertures. This combination of material excellence and functional design creates components that outperform metals and lower-grade ceramics in extreme thermal environments. Learn more about high-temperature resistant alumina properties.

2. What Is High Temperature Resistance 99% Al2O3 Ceramic Block Plate Alumina Board/Brick/Tile With Holes

2.1 Material Composition and Definition

High-temperature resistant 99% Al2O3 ceramic components are advanced technical ceramics manufactured from ≥99% pure aluminum oxide powder. These precision-engineered products include blocks, plates, bricks, and tiles featuring custom-designed hole patterns. The “99%” designation indicates premium-grade alumina with minimal sintering additives, resulting in superior thermal, mechanical, and electrical properties compared to standard 95% alumina variants. Perforations are typically created during the forming stage or precision-machined post-sintering to ensure dimensional accuracy.

2.2 Functional Design Specifications

These components exhibit exceptional thermal stability with continuous service temperatures reaching 1650°C (3000°F) in oxidizing atmospheres. Typical dimensions range from millimeters to meters, with hole diameters spanning 0.5mm to 50mm depending on application requirements. The perforated design serves multiple functions: facilitating mounting hardware for secure installation, enabling fluid/gas passage in reactor systems, reducing overall mass in aerospace applications, and accommodating thermocouples in temperature monitoring systems. Their dielectric strength (≥15 kV/mm) makes them indispensable in high-temperature electrical insulation applications.

3. How High Temperature Resistance 99% Al2O3 Ceramic Block Plate Alumina Board/Brick/Tile With Holes Was Produced

3.1 Advanced Manufacturing Process

Production begins with high-purity α-alumina powder (≥99%) blended with specialized sintering aids. The mixture undergoes spray drying to form free-flowing granules, followed by precision forming through uniaxial/isostatic pressing or injection molding. Hole patterns are created during this stage using custom tooling or via CNC machining of green bodies. Components are then sintered in high-temperature kilns at 1600-1800°C, achieving near-theoretical density. Final dimensional tolerances of ±0.1% are achieved through diamond grinding, with hole surfaces polished to Ra≤0.4μm to prevent crack initiation points.

3.2 Quality Control Protocols

Each production batch undergoes rigorous quality verification including density measurements (≥3.92 g/cm³), XRF composition analysis, and microstructure examination. Hole geometry is verified using optical comparators and CMMs to ensure positional accuracy within ±0.05mm. Thermal shock resistance is validated through standardized quench testing (RT→1000°C→water). Final inspection includes ultrasonic testing for microcracks and dielectric strength verification. This stringent process yields components with flexural strength exceeding 400 MPa, Vickers hardness ≥1500 HV, and Weibull modulus >12 for reliability in critical applications.

4. What Are The Application Fields of High Temperature Resistance 99% Al2O3 Ceramic Block Plate Alumina Board/Brick/Tile With Holes

4.1 Industrial Thermal Processing Systems

Perforated alumina components serve as essential elements in furnace construction, functioning as kiln furniture, burner plates, and heat baffles. Their thermal stability and load-bearing capacity (up to 250 MPa at 1000°C) make them ideal for sintering trays in powder metallurgy. In semiconductor manufacturing, they provide wafer support during diffusion processes with minimal contamination. The holes facilitate gas distribution in CVD reactors and allow thermocouple integration for precise temperature control. These ceramics withstand aggressive atmospheres in heat treatment furnaces where metals would rapidly degrade.

4.2 Advanced Technology and Energy Applications

In energy systems, perforated alumina plates function as separators in solid oxide fuel cells (SOFCs) operating at 800-1000°C. The holes enable uniform fuel/oxidant distribution while providing electrical insulation. Aerospace applications include thermal protection tiles with holes for fastener attachment in reentry vehicles. Laboratory settings utilize these components in specialized equipment like high-temperature reaction chambers and catalytic converter test rigs. Emerging applications include fusion reactor internal components and concentrated solar power receivers.

5. How To Choose A Good High Temperature Resistance 99% Al2O3 Ceramic Block Plate Alumina Board/Brick/Tile With Holes

5.1 Critical Material Specifications

Select components with verified 99% minimum alumina content through material certificates. Confirm density ≥3.90 g/cm³ and porosity ≤0.5% for optimal thermal performance. Evaluate dimensional tolerances – premium-grade products maintain ±0.1% dimensional stability after thermal cycling. Scrutinize hole quality: edges should be chamfered to prevent stress concentration, with surface roughness ≤0.8μm. Request manufacturer data on high-temperature flexural strength retention – quality products maintain ≥80% of RT strength at 1000°C. Verify dielectric strength ≥12 kV/mm for electrical applications.

5.2 Manufacturer Qualification and Testing

Prioritize suppliers with ISO 9001 certification and material traceability. Request third-party test reports for thermal shock resistance (minimum 10 cycles between 25°C and 1000°C without failure). Evaluate hole positioning accuracy through sample CMM reports. For corrosive environments, confirm chemical resistance data against specific acids/alkalis. Consider custom manufacturing capabilities for complex hole patterns – advanced suppliers offer laser drilling for diameters below 0.5mm. Review case studies demonstrating successful deployments in similar temperature regimes. Ensure compliance with industry-specific standards like ASTM F1466 for electronic ceramics.

6. What People Also Ask About High Temperature Resistance 99% Al2O3 Ceramic Block Plate Alumina Board/Brick/Tile With Holes

6.1 Performance and Capability Questions

Q: What maximum temperature can these perforated alumina components withstand?

A: Continuous service temperature reaches 1650°C in oxidizing atmospheres, with short-term peaks to 1750°C possible depending on loading conditions.

Q: How do holes affect the mechanical strength?

A: Properly engineered holes with appropriate edge radii reduce strength by ≤15% compared to solid components when aligned perpendicular to stress vectors.

6.2 Application and Handling Queries

Q: Can these components be used in vacuum environments?

A: Yes, 99% alumina performs exceptionally in vacuum furnaces up to 10-6 torr, with minimal outgassing after proper pre-firing treatment.

Q: How are components with holes typically mounted?

A: Installation methods include ceramic fasteners through holes, specialized hangers, or compression fitting with allowance for thermal expansion. Discover more applications in high-temperature industrial systems.

Tags: alumina ceramic, 99% Al2O3, high temperature ceramic, perforated alumina, ceramic tile with holes, alumina block, alumina plate, ceramic brick, industrial ceramics, refractory ceramic

(High Temperature Resistance 99% Al2o3 Ceramic Block Plate Alumina Board/Brick/Tile With Holes)

Supplier

Alumina Technology Co., Ltd focus on the research and development, production and sales of aluminum oxide powder, aluminum oxide products, aluminum oxide crucible, etc., serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services.