Professional Premium Aluminum Oxide Products Supplier

In the world of high-temperature processing and advanced materials research, few tools are as indispensable — yet often misunderstood — as the Alumina Crucible. Whether you’re melting precious metals, conducting ash analysis, or synthesizing ceramics, this unassuming vessel stands between success and catastrophic failure. But like any critical component, its performance hinges not just on quality at purchase, but on how it’s cleaned and maintained over time. With proper care, an Alumina Crucible can endure hundreds of thermal cycles; without it, even the most robust unit may crack, warp, or contaminate your samples. This comprehensive guide goes beyond basic usage tips to deliver a transformative, science-backed approach to preserving your investment — maximizing longevity, ensuring purity, and preventing costly setbacks.

1. What Is an Alumina Crucible?

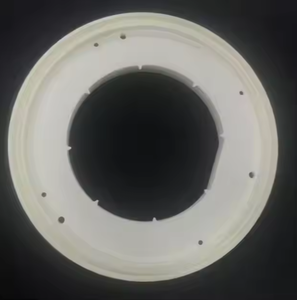

An Alumina Crucible is a container made from aluminum oxide (Al₂O₃), specifically engineered to withstand extreme temperatures, corrosive environments, and mechanical stress during laboratory and industrial processes. Renowned for its exceptional thermal stability, chemical inertness, and structural integrity, it serves as a cornerstone in applications ranging from metallurgy to analytical chemistry. Unlike conventional glassware or steel containers that deform or react under heat, alumina crucibles remain stable up to 1750°C, making them ideal for fusion reactions, calcination, and high-temperature sintering.

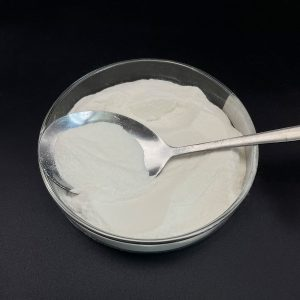

These crucibles come in various shapes and sizes — cylindrical, conical, boat-shaped — tailored to fit furnaces, muffle ovens, or induction systems. Their snow-white appearance isn’t just aesthetic; it reflects purity, with many grades exceeding 99.5% Al₂O₃ content. The material’s dense microstructure prevents porosity, minimizing contamination risks and enhancing resistance to molten salts, alkalis, and acidic fluxes. In essence, an Alumina Crucible is not merely a container — it’s a guardian of precision, shielding your experiments from impurities, thermal shock, and unpredictable failure.

For researchers, engineers, and manufacturers alike, choosing the right crucible is only half the battle. The other half lies in stewardship — understanding how to treat it with the reverence it deserves. Because while alumina is tough, it is not indestructible. Mishandling, improper cleaning, or abrupt temperature changes can lead to microfractures, spalling, or catastrophic breakage. That’s why mastering maintenance isn’t optional — it’s essential.

2. Composition of Alumina Crucible

At first glance, an Alumina Crucible appears deceptively simple — a smooth, ceramic-like vessel. But beneath the surface lies a marvel of materials science. The primary constituent is α-aluminum oxide (αAl₂O₃), a crystalline form known for its extraordinary hardness (second only to diamond and silicon carbide) and refractory properties. This phase develops during high-temperature sintering (typically above 1400°C), where amorphous alumina transforms into a tightly packed hexagonal lattice structure, granting unparalleled strength and dimensional stability.

Depending on the grade, additional dopants may be introduced to enhance specific characteristics. For example:

Magnesium oxide (MgO) is sometimes added in trace amounts (0.2–0.5%) to inhibit grain growth during sintering, resulting in finer grains and improved mechanical toughness.Zirconia (ZrO₂) can be incorporated to increase fracture resistance through transformation toughening — a mechanism where zirconia particles absorb crack energy by undergoing phase change under stress.High-purity versions avoid binders or fluxing agents entirely, ensuring minimal leachable impurities — crucial for semiconductor-grade or pharmaceutical applications.The manufacturing process involves dry pressing or isostatic molding of ultrafine alumina powder, followed by prefiring (bisque firing) and final sintering at temperatures approaching 1650°C. This yields a near-theoretical density (>98%), giving the crucible its signature low porosity (<2%) and excellent thermal conductivity. Some premium variants undergo secondary treatments such as polishing or plasma coating to further reduce surface roughness and prevent particle adhesion.

Understanding this composition is vital because it dictates how the crucible should be handled. For instance, while highly resistant to acids (except hydrofluoric acid), alumina is vulnerable to strong alkalis like sodium hydroxide or potassium carbonate at elevated temperatures. Similarly, rapid heating or cooling can exploit microscopic flaws formed during production, leading to devastating thermal shock. Thus, knowledge of what’s inside your crucible empowers smarter decisions — both in application and upkeep.

| Parameter | Specification / Value |

| Product Name | High-Purity Alumina Crucible |

| Material Composition | 99.5% – 99.8% α-Al₂O₃ (Alpha Aluminum Oxide) |

| Impurity Level (Total) | < 0.5% (Fe₂O₃: ≤50 ppm, SiO₂: ≤100 ppm, Na₂O/K₂O: ≤150 ppm) |

| Density (Bulk) | ≥ 3.65 g/cm³ |

| Apparent Porosity | ≤ 1.8% |

| Water Absorption | ≤ 0.5% |

| Flexural Strength | ≥ 350 MPa |

| Compressive Strength | ≥ 2000 MPa |

| Hardness (Vickers, HV10) | ≥ 1700 HV |

| Maximum Service Temperature | 1750°C (in oxidizing atmosphere); 1600°C (in reducing or vacuum environments) |

| Thermal Expansion Coefficient | 8.1 × 10⁻⁶ /°C (20–1000°C) |

| Thermal Conductivity | 28–30 W/(m·K) at 100°C |

| Specific Heat Capacity | ~0.88 J/(g·K) at 1000°C |

| Dielectric Strength | ≥ 15 kV/mm |

| Electrical Resistivity | > 10¹⁴ Ω·cm (at 20°C) |

| pH Stability Range | Resistant to acids (except HF); limited resistance to strong alkalis (e.g., NaOH, KOH) |

| Crucible Shapes Available | Cylindrical, Conical, Boat, Shallow Dish, Custom Designs |

| Standard Sizes (OD × ID × H) | From Ø10 mm × 8 mm × 15 mm up to Ø100 mm × 90 mm × 120 mm (custom sizes available) |

| Surface Finish | Smooth polished interior; matte exterior (Ra ≤ 1.6 μm) |

| Manufacturing Process | Dry Pressing + Isostatic Molding + High-Temperature Sintering (>1600°C) |

| Certifications | ISO 9001:2015, RoHS Compliant, REACH Pre-Registered, MSDS Available |

| Packaging | Individually wrapped in anti-static PE film, foam-lined box, desiccant included |

| Shelf Life | Unlimited when stored properly (dry, dust-free environment) |

3. Advantages and Limitations of Alumina Crucible

3.1 Key Benefits of Using Alumina Crucible

The advantages of using an Alumina Crucible are nothing short of remarkable, especially when compared to alternatives like quartz, graphite, or platinum.

3.1.1 Alumina Crucibl’s exceptional thermal resilience.

It maintains structural integrity across an enormous temperature range — from cryogenic conditions all the way up to 1750°C in oxidizing atmospheres. This makes it perfect for applications requiring repeated heating and cooling cycles without degradation.

3.1.2 Alumina Crucibl’s chemical inertness ensures minimal interaction with most reagents

Whether you’re fusing lithium tetraborate, decomposing ores with sodium peroxide, or analyzing ash content in food products, the risk of cross-contamination remains extremely low. This reliability translates directly into data accuracy — a nonnegotiable factor in scientific research and quality control.

3.1.3 Alumina exhibits outstanding mechanical strength

With a compressive strength exceeding 2000 MPa and excellent wear resistance, these crucibles resist chipping and abrasion far better than glass or porcelain equivalents. They also do not outgas toxic fumes when heated, unlike some polymer-coated or carbon-based vessels, making them safer for enclosed lab environments.

3.1.4 Alumina Crucibl’s cost efficiency

While initial pricing may be higher than disposable options, the long service life of a well-maintained Alumina Crucible delivers significant savings over time. One study found that labs replacing single-use quartz boats with reusable alumina units reduced consumable costs by up to 40% annually.

3.1.5 Alumina Crucibleasy to clean and sterilize

A feature that enhances reproducibility and minimizes downtime between experiments. When treated properly, these crucibles become trusted partners in discovery, enabling consistent results batch after batch.

3.2 Potential Drawbacks of Alumina Crucible

Despite their many strengths, Alumina Crucibles are not universally perfect.

3.2.1 Alumina Crucible’S susceptibility to alkaline attack

Prolonged exposure to molten alkalis such as NaOH, KOH, or Na₂CO₃ can cause pitting, erosion, or even complete disintegration due to the formation of soluble aluminates. Therefore, users must carefully assess compatibility before selecting a crucible for aggressive flux work.

3.2.2 Alumina Crucible’S brittleness

While strong under compression, alumina has relatively low tensile strength and poor impact resistance. Dropping a crucible onto a hard floor — even from waist height — can result in immediate cracking or shattering. Thermal shock is equally dangerous: introducing a cold crucible into a red-hot furnace can trigger sudden expansion gradients, leading to catastrophic failure.

3.2.3 Alumina conducts heat efficiently

It retains high temperatures long after removal from the furnace. This poses burn hazards if handled prematurely and requires careful cooldown procedures.

Finally, while generally inert, there remains a small risk of trace metal leaching (e.g., iron, silicon) in ultrasensitive analyses, particularly after years of use or exposure to harsh chemicals. For applications demanding absolute elemental purity, periodic replacement or rigorous validation testing may be necessary.Recognizing these limitations doesn’t diminish the value of Alumina Crucibles — rather, it underscores the importance of informed usage and meticulous maintenance.

4. Application Areas of Alumina Crucible

The versatility of the Alumina Crucible spans numerous industries and scientific disciplines. In analytical laboratories, it’s the vessel of choice for gravimetric analysis, lossonignition (LOI) tests, and XRF sample preparation, where contamination-free results are mandatory. Its ability to withstand fusion temperatures makes it ideal for preparing glass beads from mineral powders.

In metallurgy and foundry operations, alumina crucibles hold molten nonferrous metals such as copper, silver, gold, and aluminum alloys. Their nonreactive nature preserves alloy composition, ensuring accurate casting and refining outcomes.

The ceramics and advanced materials sector relies heavily on alumina crucibles for sintering functional oxides, producing ferrites, and developing piezoelectric components. Aerospace R&D teams use them in the synthesis of high-performance composites and thermal barrier coatings.

Even in pharmaceutical development, where residual solvents and catalysts must be precisely measured, alumina crucibles play a role in thermogravimetric analysis (TGA), helping determine decomposition profiles and moisture content.

Educational institutions use them for student experiments involving high-temperature reactions, benefiting from their durability and safety profile compared to more hazardous alternatives.

From nanotechnology to space exploration, wherever extreme conditions demand unwavering reliability, the Alumina Crucible proves itself indispensable.

5. How To Clean And Maintain Your Alumina Crucible

Proper cleaning and maintenance are the cornerstones of longevity for any Alumina Crucible. Follow these expert-recommended steps to extend its life and ensure consistent performance:

5.1 Cool Down Properly

Always allow the crucible to cool slowly in the furnace or on a ceramic fiber pad. Avoid quenching in water or placing it on cold metal surfaces — this induces thermal stress and increases crack risk.

5.2 Remove Residue Gently

Once cooled, remove solidified residues using wooden or plastic scrapers. Never use metal tools — they scratch the surface, creating initiation points for cracks. For stubborn deposits, soak in warm distilled water or dilute acetic acid (5–10%), but never leave immersed overnight.

5.3 Ultrasonic Cleaning (Optional)

For precision applications, ultrasonic baths with mild detergents can effectively loosen fine particles. Use only for short durations (10–15 minutes) and rinse thoroughly with deionized water afterward.

5.4 Acid Wash (When Necessary)

If contamination persists, perform a controlled acid wash using 10% nitric acid (avoid HF or strong alkalis). Soak for no more than 30 minutes, then rinse copiously with purified water and dry completely before storage.

5.5 Inspect Regularly

Check for hairline cracks, discoloration, or warping. Any visible defect indicates compromised integrity — retire the crucible immediately to prevent in-process failure.

5.6 Store Correctly

Keep in a dry, dust-free cabinet, preferably wrapped in lint-free paper or placed in sealed containers. Avoid stacking unless separated by soft padding.

6.Final Tip

Implement a usage log to track cycles, temperatures, and cleaning history. This helps predict lifespan and schedule preventive replacements. By treating your Alumina Crucible with discipline and respect, you unlock its full potential — turning a simple tool into a legacy of precision, reliability, and excellence.

Supplier

Alumina Technology Co., Ltd focus on the research and development, production and sales of aluminum oxide powder, aluminum oxide products, aluminum oxide crucible, etc., serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services. If you are looking for high quality Alumina Crucible, please feel free to contact us.

Tags: alumina crucible,crucible alumina,alumina crucible with lid