Professional Premium Aluminum Oxide Products Supplier

1. Introduction

Just 24 hours ago, a viral TikTok video reignited interest in ‘indestructible’ ceramic bakeware after a home baker claimed her alumina ceramic casserole dish survived a 500°F oven drop onto tile without a scratch. While exaggerated, the post sparked widespread curiosity: Is alumina ceramic truly ideal for baking dishes?

In this deep dive, we’ll unpack what makes alumina ceramic unique in the kitchen—and why it’s often confused with industrial-grade alumina products like thermocouple tubes or grinding discs. Spoiler: Your alumina ceramic butter dish isn’t made from the same stuff as an alumina crucible for melting steel.

2. What Exactly Is Alumina Ceramic in Cookware?

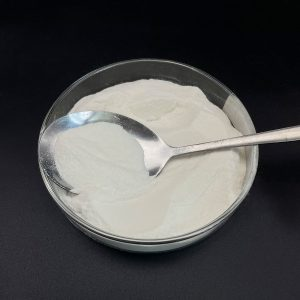

Alumina (aluminum oxide, Al₂O₃) is a ceramic compound known for hardness, heat resistance, and chemical inertness. In kitchenware, ‘alumina ceramic’ typically refers to high-alumina porcelain or stoneware—usually containing 20–60% alumina—not the 99.5% pure technical ceramics used in aerospace or lab equipment.

This distinction matters. When you buy an alumina ceramic baking dish or alumina dinner ceramic plates, you’re getting food-safe, glazed tableware enhanced with alumina for better thermal shock resistance—not an industrial alumina tube or grinding disc.

3. Comparing Alumina Ceramic Bakeware Types

3.1. Alumina Ceramic Baking Dish vs. Standard Ceramic

Standard ceramic bakeware (like earthenware) cracks easily under rapid temperature changes. Alumina-enhanced versions—such as an alumina casserole ceramic dish or alumina oven ceramic dish—handle thermal stress far better thanks to alumina’s low thermal expansion.

They also retain heat more evenly, making them excellent for slow-roasting or keeping casseroles warm. Brands like Staub sometimes use alumina-reinforced clay bodies, though ‘alumina baking dish Staub’ isn’t an official product line—it’s a consumer nickname for their dense, chip-resistant stoneware.

3.2. Glazed vs. Unglazed Alumina Ceramic

Most alumina ceramic dishes for oven use come glazed for non-porosity and easy cleaning. Unglazed versions (rare in consumer markets) are porous and better suited for decorative items like alumina ceramic plates for painting.

- Glazed alumina ceramic serving bowls resist staining from tomato sauce or turmeric.

- Unglazed pieces may absorb oils and odors, limiting food safety.

3.3. Color Variants: White, Black, and Beyond

Alumina white ceramic plates dominate the market due to traditional porcelain aesthetics. However, alumina black ceramic plates (often achieved with iron or manganese oxides) are trending for modern tablescapes.

Note: ‘Alumina ceramic black plates’ and ‘alumina black plates ceramic’ refer to the same product—marketing phrasing varies. Both maintain the same core durability if properly formulated.

4. Common Misconceptions: Kitchenware vs. Industrial Alumina

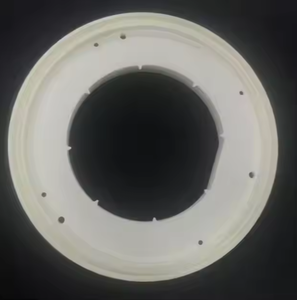

A quick Google search for ‘alumina ceramic dish’ floods results with industrial items: alumina ceramic tubes, alumina grinding discs, alumina crucibles, even alumina ceramic disc taps. These share the base material but serve entirely different purposes.

For example:

- An alumina ceramic crucible melts metals at 1,800°C; your alumina ceramic casserole with lid maxes out around 500°F.

- Alumina silicon carbide grinding discs shape pottery; they aren’t food-safe.

- Alumina ceramic plumbing pipes handle corrosive fluids—not your holiday gravy.

Consumers should focus on terms like ‘alumina ceramic serving platter’ or ‘alumina ceramic childrens plates’ to find genuine kitchenware.

5. Practical Considerations for Home Use

5.1. Oven, Microwave, and Dishwasher Safety

True alumina ceramic dishes for oven use are generally safe across all three—if labeled as such. Always check manufacturer specs. Some handcrafted pieces (e.g., alumina handcrafted ceramic plates) may lack uniform firing, risking cracks.

5.2. Specialized Items Worth Noting

Beyond baking dishes, alumina-enhanced ceramics shine in niche roles:

- Alumina ceramic butter dish with lid: Keeps butter fresh while resisting dairy stains.

- Alumina salad ceramic bowl: Large, lightweight, and chip-resistant.

- Alumina ceramic Christmas plates: Often collectible, featuring festive glazes over durable alumina clay bodies.

5.3. Price vs. Performance

Alumina ceramic plates and bowls cost 20–50% more than standard ceramic. But their longevity—resisting chipping, fading, and warping—often justifies the premium, especially for daily-use items like alumina ceramic dinner plates.

6. Conclusion

Yes, alumina ceramic is an excellent material for baking dishes and tableware—when properly formulated for food contact. Its enhanced thermal stability, strength, and aesthetic versatility make products like the alumina ceramic baking dish, alumina ceramic serving bowls, and alumina ceramic ramekins smart investments for serious home cooks.

Just remember: If your search leads you to ‘alumina diamond grinding disc for pottery’ or ‘alumina thermocouple protection tubes,’ you’ve wandered into industrial territory. Stick to kitchen-specific keywords to find the right products.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Is. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.