Professional Premium Aluminum Oxide Products Supplier

1. Introduction

In the past 48 hours, a surge in consumer interest around high-performance, non-toxic cookware has placed alumina ceramic baking dishes in the spotlight. Influencers and eco-conscious chefs are increasingly advocating for ceramic bakeware that combines durability, thermal stability, and aesthetic appeal—qualities inherent to high-alumina ceramics. This trend aligns with a broader movement toward sustainable and health-focused kitchen tools, making the alumina ceramic baking dish a timely topic for both home cooks and culinary professionals.

2. Understanding Alumina Ceramic

Alumina ceramic, primarily composed of aluminum oxide (Al₂O₃), is a high-performance engineered ceramic known for its exceptional hardness, thermal resistance, and chemical inertness. While widely used in industrial applications—from thermocouple protection tubes to grinding discs and refractory bricks—its food-safe variants have found a niche in premium kitchenware. Unlike standard earthenware or porcelain, high-purity alumina ceramics can withstand extreme temperature fluctuations without cracking, making them ideal for oven-to-table use.

3. The Alumina Ceramic Baking Dish: Features and Benefits

An alumina ceramic baking dish offers superior heat retention and even heat distribution, crucial for consistent baking results. Its non-porous surface resists staining and odor absorption, ensuring hygiene and longevity. These dishes are typically lead-free and cadmium-free, meeting stringent food safety standards. Whether labeled as an alumina baking ceramic dish or alumina oven ceramic dish, the product delivers reliable performance across roasting, baking, and serving applications.

- Resistant to thermal shock up to 1,000°C (depending on purity grade)

- Naturally non-stick when properly seasoned

- Dishwasher, microwave, and oven safe

- Available in various forms including casserole dishes with lids and ramekins

4. Versatility in the Kitchen: Beyond the Baking Dish

The appeal of alumina ceramics extends far beyond baking. Consumers are increasingly adopting coordinated sets of alumina ceramic plates and bowls for everyday and special occasions. Popular items include alumina ceramic dinner plates, alumina white ceramic plates, and even themed collections like alumina ceramic christmas plates and alumina christmas ceramic platter. For functional elegance, options such as alumina ceramic butter dish with lid, alumina ceramic sugar dish, and alumina salad ceramic bowl offer both utility and style.

Specialty items like alumina ceramic plates for painting allow for personalized tableware, while alumina ceramic childrens plates provide durable, chip-resistant options for families. The range also includes alumina ceramic serving bowls and alumina ceramic serving platter pieces, ideal for entertaining.

5. Clarifying Common Confusions

It’s important to distinguish culinary alumina ceramic ware from industrial alumina components. Terms like alumina ceramic disc taps, alumina grinding disc, alumina ceramic tube, and alumina crucible refer to technical ceramics used in engineering, not kitchenware. Similarly, alumina bricks, alumina ceramic balls, and alumina silicon carbide tubes serve high-temperature industrial processes and are not intended for food contact.

While both share the base material—aluminum oxide—the purity, additives, and manufacturing processes differ significantly. Food-grade alumina ceramics are formulated to be non-toxic and compliant with FDA or equivalent standards, whereas industrial variants may contain binders or sintering aids unsuitable for culinary use.

6. Care and Maintenance

To preserve the integrity and appearance of an alumina ceramic baking dish or related tableware, avoid sudden temperature changes (e.g., placing a hot dish directly on a cold surface). Hand washing is recommended for longevity, though most are dishwasher safe. Unlike metal bakeware, alumina ceramic does not react with acidic foods, making it ideal for tomato-based casseroles or citrus-glazed dishes.

7. Market Availability and Brands

While not all brands explicitly market their products as ‘alumina ceramic,’ high-alumina content is often implied in premium stoneware or porcelain lines. Some specialty manufacturers produce items such as alumina baking dish staub-style pieces, though Staub itself primarily uses enameled cast iron. Independent artisans also offer alumina handcrafted ceramic plates and alumina ceramic casserole with lid options through online platforms like Etsy or Amazon.

8. Conclusion

The alumina ceramic baking dish represents a fusion of advanced materials science and culinary artistry. Its unmatched thermal properties, safety, and aesthetic versatility make it a standout choice for modern kitchens. As consumers seek durable, non-toxic, and sustainable alternatives to conventional bakeware, alumina-based ceramics are poised to become a staple—not just for baking, but for complete dining experiences through coordinated alumina ceramic plates, bowls, and serving pieces.

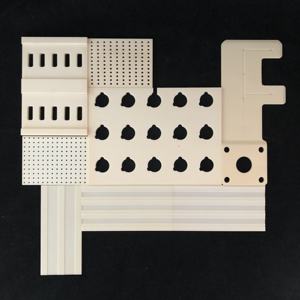

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as What. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.