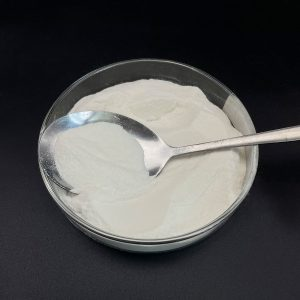

Professional Premium Aluminum Oxide Products Supplier

1. Introduction

In the past 48 hours, a surge in consumer interest in high-performance, non-toxic bakeware has been reported across major home goods retailers, driven by growing awareness of material safety and thermal efficiency in kitchenware. Leading brands like Staub and artisanal ceramic studios are witnessing increased demand for alumina-based products, particularly the alumina ceramic baking dish, prized for its resilience under extreme heat and elegant finish.

Alumina ceramic—composed primarily of aluminum oxide (Al₂O₃)—is not just an industrial material used in crucibles, tubes, and refractory bricks; it has found a refined niche in culinary applications. This article explores the unique attributes of alumina ceramic baking dishes and related tableware, compares their performance against conventional alternatives, and examines the breadth of products available, from the humble alumina ceramic butter dish to the sophisticated alumina ceramic casserole with lid.

2. Material Science Behind Alumina Ceramic Bakeware

2.1. Composition and Thermal Properties

Alumina ceramic typically contains 90–99.8% aluminum oxide, which imparts exceptional thermal stability, withstanding temperatures up to 1,700°C in industrial contexts. While kitchenware uses lower-purity formulations for cost and workability, even 70–85% alumina content ensures oven safety up to 500°F (260°C) or higher. This makes alumina ceramic dishes for oven use far more reliable than standard earthenware or stoneware, which may crack under thermal shock.

2.2. Non-Porosity and Food Safety

Unlike porous ceramics, high-alumina formulations are vitrified during firing, creating a nonporous, inert surface. This prevents bacterial growth, flavor absorption, and chemical leaching—critical for items like the alumina ceramic sugar dish or alumina butter ceramic dish with lid, which store sensitive ingredients.

3. Comparative Analysis: Alumina vs. Other Bakeware Materials

3.1. Alumina Ceramic vs. Stoneware and Porcelain

Traditional stoneware often contains lower alumina content and higher flux materials, reducing its thermal shock resistance. Porcelain, while elegant, may lack the structural integrity of alumina-enhanced ceramics. In contrast, an alumina oven ceramic dish maintains dimensional stability during rapid temperature changes, making it ideal for roasting, baking, and broiling.

3.2. Alumina vs. Metal and Glass Bakeware

Metal pans conduct heat quickly but can react with acidic foods and lack the even heat distribution of ceramic. Glass (e.g., Pyrex) is non-reactive but prone to shattering under thermal stress. Alumina ceramic baking dishes offer a balanced solution: slow, even heating with superior durability and no reactivity.

4. Product Range and Functional Specialization

4.1. Everyday and Decorative Tableware

Beyond baking, alumina’s versatility extends to dinnerware and serveware. Consumers increasingly seek alumina ceramic dinner plates, alumina white ceramic plates, and even alumina black ceramic plates for their scratch resistance and modern aesthetic. Seasonal items like alumina christmas plates ceramic and alumina christmas ceramic platter combine festive design with functional robustness.

4.2. Specialized Kitchenware

The market now includes niche items such as alumina ceramic plates for painting (used in craft and culinary plating), alumina ceramic childrens plates (chip-resistant and lead-free), and alumina salad ceramic bowl sets. Even small-format items like alumina ceramic ramekins and alumina ceramic butter dish with lid benefit from the material’s thermal and chemical inertness.

5. Industrial Parallels: Why Kitchen Alumina Matters

Interestingly, the same alumina used in high-temperature applications—such as alumina ceramic tubes for furnace use, alumina crucibles for melting metals, and alumina refractory bricks—shares foundational properties with culinary alumina ceramics. While kitchenware doesn’t require 99.5% purity, the engineering principles of thermal shock resistance, hardness, and chemical stability are directly transferable.

For instance, the manufacturing process for an alumina ceramic casserole dish mirrors that of alumina ceramic grinding discs or alumina ceramic disc taps in terms of sintering control and density management, albeit at lower performance thresholds.

6. Care, Longevity, and Sustainability

Alumina ceramic dishes for oven use are dishwasher-safe, microwave-compatible, and resistant to staining. Their longevity reduces the need for frequent replacement, aligning with sustainable kitchen practices. Unlike non-stick coatings that degrade, alumina’s surface remains intact for decades with proper handling.

7. Conclusion

The alumina ceramic baking dish represents a convergence of industrial-grade material science and culinary artistry. From the practical alumina oven dish ceramic to the decorative alumina ceramic serving platter, these products offer unmatched thermal performance, safety, and aesthetic flexibility. As consumers prioritize health, durability, and sustainability, alumina-based ceramics are poised to become the gold standard in modern bakeware and tableware.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as What. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.