Professional Premium Aluminum Oxide Products Supplier

In the intricate globe of industrial chemistry and catalytic procedures, the selection of a stimulant service provider can make or break the effectiveness and sustainability of a reaction. Among the myriad products readily available, Alumina Ceramic Balls have become a game-changer, supplying unparalleled efficiency in terms of toughness, chemical stability, and functional versatility. Whether you’re a chemical engineer maximizing a reactor system, a researcher discovering green chemistry solutions, or a commercial supervisor looking for cost-effective advancements, understanding why Alumina ceramic Balls are the best material for stimulant providers is important. This post will certainly look into their chemical structure, core residential or commercial properties, advantages, limitations, and diverse applications– supplying an extensive overview to their transformative potential.

1. Chemical Structure of Alumina Ceramic Balls

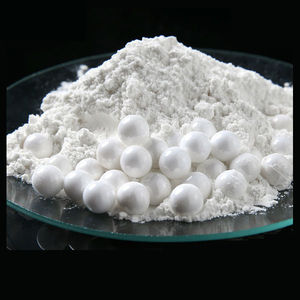

1.1 What Are Alumina Ceramic Balls?

Alumina ceramic Balls, additionally referred to as aluminum oxide ceramic rounds, are high-performance materials made up mainly of lightweight aluminum oxide (Al ₂ O 3). These round bits are crafted to possess a precise microstructure, combining porosity, mechanical stamina, and chemical inertness. Unlike conventional inert supports such as silica gel or activated carbon, alumina ceramic spheres are manufactured through innovative sintering techniques, ensuring harmony and consistency in their physical and chemical properties.

The manufacturing procedure starts with high-purity alumina powder, which is blended with binding agents and formed right into spherical shapes. After being subjected to high-temperature sintering (usually 1,600– 1,800 ° C), the product attains its characteristic impermeable or macroporous structure, depending on the designated application. This precise design leads to a material that is not just robust but also customized to fulfill the demanding needs of catalytic systems.

1.2 What Is The Chemical Structure Of Alumina ceramic Balls?

At the molecular degree, Alumina ceramic Balls are made up of a crystalline latticework of lightweight aluminum and oxygen atoms set up in a hexagonal close-packed structure. This plan imparts exceptional thermal stability and chemical resistance, making the material ideal for high-temperature and destructive environments. The absence of amorphous phases ensures minimal leaching of metallic ions, which is essential for preserving the pureness of catalytic responses.

In addition, the material’s surface area can be customized with pore design to improve its adsorption ability and surface. For instance, microporous alumina (with pore sizes <2 nm) is often used for small-molecule reactions, while mesoporous alumina (2– 50 nm pores) masters large-molecule catalysis. This versatility underscores the material’s role as an adjustable platform for diverse commercial applications.

2. Core characteristics of Alumina ceramic Balls

2.1 Physical And Chemical Qualities

The physical and chemical properties of Alumina ceramic Balls are the keystone of their prevalence as stimulant service providers. Key qualities include:

High Thermal Stability: Enduring temperatures as much as 1,800 ° C, these rounds remain structurally undamaged even in severe thermal problems. This makes them perfect for high-temperature responses like fracturing or gasification.

Chemical Inertness: Resistant to acids, bases, and natural solvents, they stop undesirable side reactions that might deteriorate catalysts or contaminate products.

Mechanical Toughness: A firmness of 9 Mohs (2nd only to ruby) guarantees minimal damage, also in abrasive environments.

Reduced Thickness: Weighing roughly 3.9 g/cm FOUR, they decrease the overall mass of catalytic systems, enhancing power performance.

High Porosity: Adjustable pore sizes (varying from 0.1 μm to 500 μm) allow for optimal mass transfer and reactant diffusion.

For example, the ALO300 Collection Alumina ceramic Balls boast an area of 150– 300 m ²/ g, making it possible for efficient adsorption of catalytic energetic sites. This property is essential in applications like CO₂ capture or hydrogen storage space, where surface communications dominate reaction kinetics.

2.2 Functional Qualities

Past their intrinsic residential or commercial properties, Alumina ceramic Balls use functional advantages that amplify their energy:

Stimulant Diffusion: Their porous framework ensures consistent distribution of catalytic nanoparticles, protecting against heap and making the most of energetic site scheduling.

Thermal Shock Resistance: Sudden temperature level changes seldom create splitting or delamination, an unusual concern with weak products like silica.

Regenerability: After deactivation, these rounds can be recouped and reused through easy cleaning or calcination, reducing long-term operational costs.

Environmental Compatibility: Devoid of heavy metals and hazardous residues, they align with green chemistry concepts and regulative standards.

The ALO500 Collection, as an example, is crafted with slope porosity, enabling it to support both acidic and fundamental drivers in a single system– an innovation for multifunctional activators.

| Parameter | Specification | Notes |

| Color | White | Pure white, no additives |

| Shape | Spherical | Uniform granules for consistent packing |

| Grain Size | 3–50 mm (Customizable) | Standard sizes: 3, 6, 10, 16, 25 mm |

| Bulk Density | 3.45 g/cm³ | High density for compact systems |

| Porosity | ≤7.0% (Apparent Porosity) | Low porosity for inert applications |

| Hardness | >8.0 Mohs Scale | Exceptional wear resistance |

| Water Absorption | <4.0 wt.% | Ensures durability in wet environments |

| Acid Resistance | >99.8% | Resists corrosion in acidic media |

| Thermal Conductivity | 0.7–0.8 W/m²·K | Efficient heat dissipation |

| Thermal Expansion | 0.10% at 500°C | Stable under thermal stress |

| Thermal Shock Resistance | 10 cycles at 1000°C → Water Quench | Outstanding thermal stability |

| Maximum Operating Temperature | 1550°C (2822°F) | Suitable for extreme heat applications |

3. Why Are Alumina ceramic Balls The Best Product For Driver Carriers?

The inquiry continues to be: Why are Alumina Ceramic Balls the very best product for catalyst service providers? The response lies in their capacity to bridge the gap between efficiency and practicality in catalytic systems. Below’s a failure of their unequaled benefits:

3.1 Unparalleled Toughness

Catalytic procedures usually operate under severe conditions– heat, corrosive chemicals, and mechanical stress and anxiety. Alumina Ceramic Balls grow in such atmospheres, outmatching choices like carbon-based supports or metal oxides. As an example, in petrochemical breaking, where temperatures exceed 800 °C, alumina spheres keep architectural honesty, whereas carbon supports weaken rapidly.

3.2 Precision Design

Modern production strategies allow for tailored porosity, surface area chemistry, and mechanical properties. This accuracy makes sure that the spheres can be enhanced for particular responses. For instance, acid-treated alumina improves proton conductivity in gas cell stimulants, while alkalimodified surfaces boost basicity for CO ₂ conversion.

3.3 Cost-Efficiency in Time

While the preliminary financial investment in Alumina ceramic Balls may be greater than some choices, their long lifespan, regenerability, and reduced upkeep demands lead to substantial expense savings over time. Research studies reveal that aluminabased systems can decrease catalyst replacement prices by up to 40% compared to silicabased counterparts.

3.4 Environmental and Safety, And Security Conveniences

In an era where sustainability is paramount, Alumina ceramic Balls stand out. Their harmless nature, recyclability, and low ecological footprint make them a recommended selection for industries intending to fulfill EPA or ISO 14001 standards. For instance, in wastewater therapy, alumina service providers make it possible for the regeneration of invested catalysts without releasing dangerous by-products.

4. Advantages and disadvantages of Alumina ceramic Balls

4.1 Advantages

Superior Thermal and Chemical Security: Perfect for extreme conditions.

High Surface Area and Pore Volume: Boosts catalytic effectiveness.

Long Lifespan and Regenerability: Decreases waste and operational expenses.

Adjustable Qualities: Versatile for diverse applications.

Eco Friendly: Aligns with environment-friendly production goals.

4.2 Disadvantages

Greater Initial Cost: Compared to materials like activated carbon.

Fragile Nature: Needs cautious handling to avoid damage throughout setup.

Minimal Adaptability fit: Spherical kinds may not suit all activator geometries.

Regardless of these disadvantages, the long-term advantages of Alumina ceramic Balls far outweigh their limitations, particularly in high-value applications.

5. Application areas of Alumina ceramic Balls

The flexibility of Alumina ceramic Balls extends across commercial, ecological, and energy markets. Key applications consist of:

5.1 Industrial Catalysis

Petrochemical Handling: Used in liquid catalytic splitting (FCC) to boost hydrocarbon conversion.

Drug Synthesis: Supports chiral stimulants for uneven responses.

Polymerization Reactions: Function as a stable assistance for Ziegler-Natta catalysts in plastic production.

5.2 Environmental Applications

Air Purification: Removes volatile organic compounds (VOCs) through oxidation catalysts.

CO₂ Capture and Application: Assists in carbon mineralization in carbon-negative technologies.

Wastewater Therapy: Improves photocatalytic destruction of dyes and heavy metals.

5.3 Energy Field

Gas Cells: Works as a proton-conducting material in solid oxide gas cells (SOFCs).

Hydrogen Manufacturing: Improves heavy steam methane reforming (SMR) efficiency.

Thermal Power Storage: Stores and launches heat in focused solar power (CSP) systems.

5.4 Emerging Technologies

Nanotechnology: Acts as a scaffold for nanoparticle synthesis in quantum dot manufacturing.

Biocatalysis: Sustains immobilized enzymes in biofuel refining and biomedical research.

6.Conclusion: A Catalyst Carrier Transformation

To conclude, Alumina Ceramic Balls are not just a product– they are a cutting-edge enabler of lasting and effective catalytic processes. Their extraordinary longevity, customizable functionality, and eco-friendly profile set them as the gold standard in driver service provider technology. From industrial reactors to eco-friendly power remedies, these rounds empower industries to minimize expenses, boost efficiency, and satisfy international sustainability goals.

For businesses seeking to remain competitive in a quickly progressing market, taking on Alumina Ceramic Balls is a necessary tactic. Whether you’re maximizing a petrochemical plant or introducing a carbon-negative startup, this product offers the precision, integrity, and scalability required to drive innovation. Embrace the future of catalysis– with stamina, quality, and purpose– through the unequaled power of Alumina ceramic Balls.

Supplier

Alumina Technology Co., Ltd focus on the research and development, production and sales of aluminum oxide powder, aluminum oxide products, aluminum oxide crucible, etc., serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services. If you are looking for high quality Alumina Ceramic Balls , please feel free to contact us. (nanotrun@yahoo.com)

Tags: alumina balls,alumina ceramic balls,alumina spheres