Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

Overview of 0.5L 1L 1.5L 2L 3L 5L 10L 12L Aluminum Oxide Alumina Al2o3 Ceramic Horizontal Ball Milling Jar

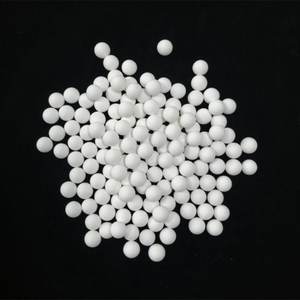

Alumina balls are high-purity ceramic grinding media known for their exceptional hardness, wear resistance, and thermal stability. Ideal for industrial applications like milling, catalysis, and wear-resistant components.

Features of 0.5L 1L 1.5L 2L 3L 5L 10L 12L Aluminum Oxide Alumina Al2o3 Ceramic Horizontal Ball Milling Jar

High mechanical strength & durability

Excellent chemical & thermal stability

Superior wear & corrosion resistance

Available in various sizes & purity grades

Low contamination for precision processes

(0.5L 1L 1.5L 2L 3L 5L 10L 12L Aluminum Oxide Alumina Al2o3 Ceramic Horizontal Ball Milling Jar)

Specification of 0.5L 1L 1.5L 2L 3L 5L 10L 12L Aluminum Oxide Alumina Al2o3 Ceramic Horizontal Ball Milling Jar

This alumina ceramic milling container deals with challenging grinding work. Alumina ceramic is really tough. It gauges 9 on the Mohs scale. This product is likewise dense. Density is about 3.9 grams per cubic centimeter. These properties make it wear-resistant. It lasts a lot longer than steel jars. Contamination is a large issue in milling. Alumina ceramic addresses this. It keeps your products pure. The pureness degree is high. It’s typically 99.5% or far better. You obtain tidy outcomes each time.

The jar comes in lots of sizes. Choose what fits your machine. Options consist of 0.5 L, 1L, 1.5 L, 2L, 3L, 5L, 10L, and 12L abilities. The layout is straight. This shape functions well for sphere milling. It allows reliable grinding media activity. Wall thickness corresponds. It’s normally around 20mm thick. This density supplies strength. It takes care of the pressure inside during procedure. The container remains intact under hefty usage.

Temperature level modifications take place during milling. Alumina ceramic handles thermal shock well. It will not break conveniently. This reliability is essential for long runs. The smooth inner surface area matters. It minimizes product sticking. Your product moves easily. Tidying up is simpler as well. These jars work in many sectors. Labs use them for study. Paint manufacturing facilities use them for pigments. Ceramics manufacturers use them for powders. Electronic devices firms use them for products. They are functional tools.

(0.5L 1L 1.5L 2L 3L 5L 10L 12L Aluminum Oxide Alumina Al2o3 Ceramic Horizontal Ball Milling Jar)

Applications of 0.5L 1L 1.5L 2L 3L 5L 10L 12L Aluminum Oxide Alumina Al2o3 Ceramic Horizontal Ball Milling Jar

Our aluminum oxide ceramic milling jars come in dimensions from 0.5 L to 12L. These jars are constructed for grinding and mixing tasks. They work in labs and manufacturing facilities. Alumina ceramic is extremely tough. It lasts longer than steel jars. This material will not rust or corrode. Chemicals don’t harm it. You avoid contamination in your products. That’s essential for pure results.

These containers match numerous industries. Pharmaceutical business use them. They grind energetic components finely. Electronic devices makers need uniform bit sizes. These jars deliver that. Paint producers blend pigments evenly. Ceramic artists mix glazes without impurities. Study labs evaluate new materials accurately.

Different dimensions fit various demands. Tiny 0.5 L jars are for tiny batches. They save area. Mid-size containers like 1L or 2L take care of daily laboratory job. Larger 5L to 12L containers are for bulk production. They cut down handling time. Every size makes use of the very same challenging alumina.

The horizontal style rotates efficiently. It spreads grinding media evenly. This provides consistent fragment reduction. You obtain uniform powders every run. The containers seal snugly. No leakages occur during procedure. They fit conventional sphere mills conveniently. Configuration is basic. Cleaning fasts also.

Choose alumina jars for hard grinding jobs. They outshine plastic or metal alternatives. Your products stay pure. Your procedure stays effective.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 0.5L 1L 1.5L 2L 3L 5L 10L 12L Aluminum Oxide Alumina Al2o3 Ceramic Horizontal Ball Milling Jar

What sizes do these Alumina jars come in?

You get multiple size choices. We stock jars from 0.5 liters up to 12 liters. Common volumes are 0.5L, 1L, 1.5L, 2L, 3L, 5L, 10L, and 12L. This covers different milling needs. Small jars suit lab tests. Bigger jars handle larger production batches.

Why use Aluminum Oxide (Al2O3) for milling jars?

Alumina is very hard. It resists wear extremely well. This minimizes contamination. Alumina jars handle tough chemicals. Acids won’t damage them. Bases won’t damage them either. They are chemically inert. This keeps your materials pure. They withstand high impacts inside the mill.

How do I clean the jar after milling?

Cleaning is straightforward. Use common solvents like acetone or ethanol first. Rinse well with water. Stubborn residues need mechanical cleaning. Use Alumina balls inside the jar with water or solvent. Run the mill briefly. This scrubs the inner walls effectively. Avoid harsh tools that scratch.

How long will an Alumina jar last?

Jar life varies. It depends on your milling material. Hard materials wear the jar faster. Milling speed matters. Higher speeds increase wear. Ball size and charge affect it too. Proper use gives long service. Expect months or years of regular use. Check the jar interior periodically for wear.

What are these jars mainly used for?

They are essential for ball milling. Grind and mix powders finely. They work in horizontal ball mills. Labs use them for research. Industries use them for material production. Common applications include ceramics, chemicals, paints, and pharmaceuticals. They grind hard materials like metals and minerals reliably.

(0.5L 1L 1.5L 2L 3L 5L 10L 12L Aluminum Oxide Alumina Al2o3 Ceramic Horizontal Ball Milling Jar)

REQUEST A QUOTE

RELATED PRODUCTS

Special Grade Furnace Used High Alumina Refractory Balls For Hot Air Furnace

Good Al2O3 Wear Resistant Ball 92% High Alumina Ceramic Ball Grinding

Factory Zibo Grinding Media 92% Aluminum Oxide Al2O3 Alumina Ceramic Balls for Ball Mill

High Hardness Wear-resistant Bearing Balls Alumina Ceramic Ball for 3mm to 50mm Custom

High Hardness Alumina Purity 92% 95% Ceramic Alumina Grinding Ball for Wet Dry Grinding Machine