Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

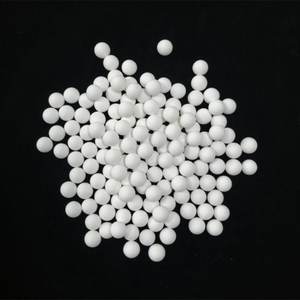

Overview of 3mm 5mm 6mm 10mm 92% Alumina Ball Ceramic Grinding Beads Ball

Alumina balls are high-purity ceramic grinding media known for their exceptional hardness, wear resistance, and thermal stability. Ideal for industrial applications like milling, catalysis, and wear-resistant components.

Features of 3mm 5mm 6mm 10mm 92% Alumina Ball Ceramic Grinding Beads Ball

High mechanical strength & durability

Excellent chemical & thermal stability

Superior wear & corrosion resistance

Available in various sizes & purity grades

Low contamination for precision processes

(3mm 5mm 6mm 10mm 92% Alumina Ball Ceramic Grinding Beads Ball)

Specification of 3mm 5mm 6mm 10mm 92% Alumina Ball Ceramic Grinding Beads Ball

These ceramic grinding grains utilize top-grade alumina product. They supply 92% purity. This high alumina web content provides phenomenal solidity. It likewise provides outstanding wear resistance. You get long life span in demanding grinding applications. These beads withstand considerable impact forces. They stand up to breaking and fracturing successfully.

Pick from a number of functional dimensions: 3mm, 5mm, 6mm, and 10mm diameters. The little 3mm beads stand out at ultra-fine grinding. They generate really slim fragment distributions. The 5mm grains handle basic fine grinding tasks well. They stabilize grinding performance and grain stamina. The 6mm beads match medium-fine grinding operations. They use excellent influence resistance. The large 10mm grains deal with crude grinding. They break down hard materials effectively.

Density is a crucial efficiency variable. These alumina grains have high thickness. High density suggests better kinetic energy during milling. This equates to much faster grinding rates. You accomplish your target particle dimension quicker. Grinding performance boosts significantly.

Chemical stability is one more significant advantage. These grains withstand solid acids and alkalis. They take care of harsh slurries accurately. They keep stability in harsh chemical atmospheres. This stability prevents contamination of your product. Product pureness stays high.

These beads execute well under high temperatures. They suit numerous milling devices. Use them in round mills successfully. Utilize them in attritors properly. Use them in vibratory mills successfully. They work for grinding minerals continually. They work for grinding ceramics consistently. They work for grinding paints regularly. They help grinding electronic products consistently. They provide regular, reputable results set after set.

(3mm 5mm 6mm 10mm 92% Alumina Ball Ceramic Grinding Beads Ball)

Applications of 3mm 5mm 6mm 10mm 92% Alumina Ball Ceramic Grinding Beads Ball

These 3mm, 5mm, 6mm, and 10mm ceramic grinding beads are made from 92% alumina. They are really hard. They withstand wear exceptionally well. These rounds are necessary devices for grinding and spreading products. They are utilized in several sectors.

For paints and inks, these grains damage down pigments carefully. They develop smooth, constant shades. The small 3mm beads work well for ultra-fine bits. The 5mm beads are an usual option for basic grinding jobs below.

The chemical sector relies on these beads. They grind chemical powders efficiently. The beads withstand rough chemicals. They do not pollute sensitive products. Sizes like 5mm and 6mm are preferred for chemical milling.

Pharmaceutical firms utilize them also. They grind active components and excipients. The grains supply high pureness. They are inert. They satisfy rigorous sector requirements. Smaller beads like 3mm make certain extremely great powders for medicines.

Digital materials need precise grinding. These alumina grains deliver. They grind products like ceramics and ferrites. They provide regular particle dimension control. This is important for electronic part performance. The 6mm and 10mm grains handle tougher products well.

Mining operations use these grains for ore grinding. They are a lot harder than steel balls. They last longer. They reduce running prices substantially. The bigger 10mm beads are good for first rugged grinding phases. The smaller grains attain better results later. They operate in sphere mills and attritors effectively.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 3mm 5mm 6mm 10mm 92% Alumina Ball Ceramic Grinding Beads Ball

Customers often ask about these ceramic grinding beads. We answer the top questions here. What are these beads made from? These beads use 92% alumina ceramic. This material is very hard. It resists wear extremely well. It handles tough grinding jobs. Why choose these alumina beads? They last much longer than other materials. They save money over time. They grind materials efficiently. They keep your product pure. They cause minimal contamination. What sizes are available? We offer 3mm, 5mm, 6mm, and 10mm beads. Different sizes suit different machines. Different sizes suit different materials. Pick the size matching your mill. Pick the size matching your material fineness. Small beads like 3mm make very fine particles. Larger beads like 10mm handle bigger chunks first. Where are these beads typically used? They work in many industries. Paint and ink makers use them. Ceramic powder producers use them. Chemical companies use them. They grind minerals. They grind pigments. They grind many other materials needing fine particles. How do I care for them? Store them dry. Keep them away from strong impacts before use. Check them regularly. Replace worn beads. This keeps grinding efficient. Follow your mill’s operating guidelines. This ensures the best bead life.

(3mm 5mm 6mm 10mm 92% Alumina Ball Ceramic Grinding Beads Ball)

REQUEST A QUOTE

RELATED PRODUCTS

Industrial Wear-Resistant Alumina Ceramic Ball Media White Inert Ceramic Alumina Processing Services Welding Cutting Bending

3mm 6mm 20mm 17% 25% 30% 40% 75% 90% Al2O3 Inert Alumina Ceramic Ball High Aluminum Ceramic Ball As Catalyst Support Media

68% High Alumina Ceramic Ball Manufacture With Factory

High Alumina Ceramic Balls , Bubble Alumina

Factory Manufactured Inert Ceramic Ball 3mm~50mm Alumina 99% 95% 92% Concentration