Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

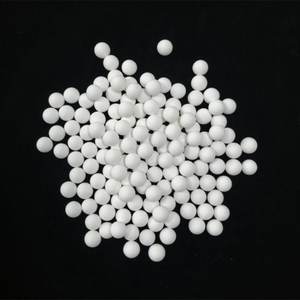

Overview of 3mm 6mm 10mm High Strength Factory Ceramic Support Media 17-23% Alumina Ceramic Balls for Hydroprocessing Application

Alumina balls are high-purity ceramic grinding media known for their exceptional hardness, wear resistance, and thermal stability. Ideal for industrial applications like milling, catalysis, and wear-resistant components.

Features of 3mm 6mm 10mm High Strength Factory Ceramic Support Media 17-23% Alumina Ceramic Balls for Hydroprocessing Application

High mechanical strength & durability

Excellent chemical & thermal stability

Superior wear & corrosion resistance

Available in various sizes & purity grades

Low contamination for precision processes

(3mm 6mm 10mm High Strength Factory Ceramic Support Media 17-23% Alumina Ceramic Balls for Hydroprocessing Application)

Specification of 3mm 6mm 10mm High Strength Factory Ceramic Support Media 17-23% Alumina Ceramic Balls for Hydroprocessing Application

These are ceramic support media balls. They come in sizes. The sizes are 3mm, 6mm, and 10mm. These balls are very strong. They are made in a factory. The material is ceramic. This ceramic has alumina. The alumina amount is between 17% and 23%. These balls are for hydroprocessing. Hydroprocessing is a refining process. It happens in oil refineries. It uses high pressure. It uses high temperature. It needs hydrogen gas.

The balls go into reactors. They sit under the catalyst. They support the catalyst bed. They keep catalyst pellets in place. This is important. It stops catalyst movement. It prevents crushing. It avoids packing too tight. This helps fluids flow. It reduces pressure drop. Pressure drop is energy loss. Lower pressure drop saves money. It improves efficiency.

The balls are hard. They resist wear. They handle high temperatures. They withstand chemical attack. This strength matters. Hydroprocessing conditions are harsh. Equipment lasts longer with strong balls. Downtime decreases. Maintenance costs go down.

The alumina percentage is key. It gives good hardness. It offers decent chemical resistance. It provides enough strength. It is cost-effective. Higher alumina balls exist. They cost more. They are harder. They resist chemicals better. But 17-23% alumina works well. It balances performance and price.

You use these balls in hydrotreaters. You use them in hydrocrackers. These are common hydroprocessing units. The balls support catalyst beds. They ensure even flow distribution. They protect expensive catalysts. They help the unit run smoothly. Choosing the right size matters. The 3mm balls are for very small catalyst. The 6mm balls are standard. The 10mm balls handle larger catalyst or higher flows. Pick the size based on your catalyst size and reactor design.

(3mm 6mm 10mm High Strength Factory Ceramic Support Media 17-23% Alumina Ceramic Balls for Hydroprocessing Application)

Applications of 3mm 6mm 10mm High Strength Factory Ceramic Support Media 17-23% Alumina Ceramic Balls for Hydroprocessing Application

These ceramic balls come from the factory. They are very strong. The sizes are 3mm, 6mm, and 10mm. They contain 17-23% alumina. These balls are for hydroprocessing. Hydroprocessing happens in oil refineries. Reactors use special catalysts. The catalysts need support. This is where the ceramic balls work. They sit at the bottom of the reactor. They also sit on top of the catalyst bed. The balls create a strong base. This base stops the catalyst from packing too tight. Packed catalyst is bad. It blocks the flow. Liquids and gases cannot move well. The balls keep space open. This space lets fluids pass through easily. The flow stays even across the whole bed. Uneven flow causes problems. It makes the catalyst work poorly. It can damage the reactor. The balls prevent this. They spread the fluids out. Different sizes are used together. The smaller balls go on top. The bigger balls go below. This layering works best. It supports the fine catalyst powder. The powder cannot fall through the gaps. The balls are very tough. They handle high pressure. They handle high heat. They resist chemicals in the reactor. They do not break down easily. This strength is important. It means the balls last a long time. Factories make them to strict standards. The quality is controlled. You get reliable performance. Using these balls improves hydroprocessing. It makes the reactor run smoother. It protects the expensive catalyst. It helps the unit work efficiently.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 3mm 6mm 10mm High Strength Factory Ceramic Support Media 17-23% Alumina Ceramic Balls for Hydroprocessing Application

What are ceramic support media balls? They are small, hard balls used inside reactors. They sit below catalysts. They help spread liquids and gases evenly. This improves reactor performance.

Why use ceramic balls in hydroprocessing? Hydroprocessing needs tough materials. These balls handle high pressure and temperature well. They resist chemicals too. They keep catalysts working longer and better.

How do the sizes matter? 3mm, 6mm, and 10mm sizes offer choices. Small 3mm balls fit tight spaces well. 6mm is a common middle size. 10mm balls suit larger catalyst particles. Picking the right size is key for good flow and support.

What does 17-23% alumina mean? Alumina makes the balls strong. This range offers good balance. It provides needed strength without being too brittle. It helps the balls last under tough conditions.

Why is high strength important? Reactors are demanding places. Strong balls resist breaking and crushing. They won’t crumble under weight or pressure. This means less downtime and lower costs.

(3mm 6mm 10mm High Strength Factory Ceramic Support Media 17-23% Alumina Ceramic Balls for Hydroprocessing Application)

REQUEST A QUOTE

RELATED PRODUCTS

Good Al2O3 Wear Resistant Ball 92% High Alumina Ceramic Ball Grinding

Industrial Catalyst Support Media Packing Ceramic Alumina Ball High Quality Ceramic Parts

Refractory 68% 75% 80% 92% Inert Al2O3 Grinding Polishing High Alumina Ceramic Ball for Ball Mill

Spherical Activ Alumina Ball Best Activ Alumina

92% 95% Grinding Mill Industrial Ceramic Inert Alumina White Wear Resistant Alumina Ceramic 95 Aluminium Ball