Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

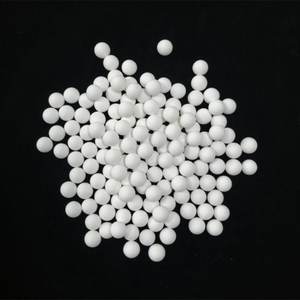

Overview of 6mm 13mm 19mm Inert Alumina Ceramic Media Alumina Inert Ball for Catalyst Support Media

Alumina balls are high-purity ceramic grinding media known for their exceptional hardness, wear resistance, and thermal stability. Ideal for industrial applications like milling, catalysis, and wear-resistant components.

Features of 6mm 13mm 19mm Inert Alumina Ceramic Media Alumina Inert Ball for Catalyst Support Media

High mechanical strength & durability

Excellent chemical & thermal stability

Superior wear & corrosion resistance

Available in various sizes & purity grades

Low contamination for precision processes

(6mm 13mm 19mm Inert Alumina Ceramic Media Alumina Inert Ball for Catalyst Support Media)

Specification of 6mm 13mm 19mm Inert Alumina Ceramic Media Alumina Inert Ball for Catalyst Support Media

These alumina ceramic balls are for driver assistance. They are available in three dimensions: 6mm, 13mm, and 19mm diameter. You pick the dimension based upon your activator design and stimulant requirements. Smaller sized rounds give more area. Larger spheres handle greater circulation prices better.

The product is inert alumina ceramic. This means it won’t react with most chemicals. It stays stable even in tough problems. High purity is crucial. Impurities can damage your driver or process. These rounds are very pure.

They are exceptionally solid. Their crush stamina is extremely high. This quits them damaging under stress in your reactor. They take care of the weight of the stimulant bed well. They additionally stand up to wear over time. This prolongs their functional life.

Heat resistance is outstanding. They deal with really heats quickly. This is vital for several catalytic processes. Thermal shock resistance is likewise high. They survive quick temperature changes without splitting. This is important during startup or shutdown.

The surface is really smooth and thick. This prevents cleaning. Dust can obstruct your system. The uniform form makes certain even flow distribution. This assists your catalyst job efficiently. Consistent dimension keeps stress decline predictable.

These spheres supply steady, inert physical support for your catalyst. They shield the driver pellets. They guarantee great fluid circulation with the reactor. Their integrity indicates much less downtime for replacement. They are a trustworthy selection for requiring applications.

(6mm 13mm 19mm Inert Alumina Ceramic Media Alumina Inert Ball for Catalyst Support Media)

Applications of 6mm 13mm 19mm Inert Alumina Ceramic Media Alumina Inert Ball for Catalyst Support Media

These alumina ceramic balls are inert. They do not react. They are really hard. They resist chemicals well. They take care of heats conveniently. They are available in 3 sizes: 6mm, 13mm, and 19mm. Their dimension is precise. Their shape is completely round. This makes them extremely consistent. They are suitable for sustaining catalysts.

Their major work is to hold stimulant materials in place. They do this inside reactors. Activators are big vessels where chemical reactions occur. The spheres produce a solid, stable bed. This bed supports the driver bits. The driver bits are usually smaller. The spheres maintain the catalyst from walking around way too much. They quit the catalyst from packing down tightly. This packaging is bad. It obstructs the circulation of gases or fluids. The balls prevent this clog. Excellent flow is essential. It lets the chemicals get to the driver properly. The reaction takes place efficiently.

The balls are solid. They withstand crushing forces. They last a long time. They are inert. They do not contaminate the process. This is vital for product purity. They function well in petrochemical plants. They are used in oil refineries. They are common in chemical manufacturing systems. They manage difficult conditions. These include high pressure and warm. They also resist corrosion. Numerous chemicals are harsh.

The various sizes serve details requirements. Smaller 6mm balls fill up voids better. They sustain very great catalysts. They are great where room is restricted. Medium 13mm rounds are a common choice. They provide an excellent equilibrium. They sustain lots of driver kinds well. Larger 19mm rounds supply optimal stamina. They handle the heaviest loads. They are best for large activators. They ensure secure circulation in large systems. The best dimension depends upon the catalyst utilized. It also depends upon the activator layout.

These alumina rounds shield the driver. They maintain the right reactor problems. They make sure reactions run efficiently. They assist plants operate reliably. They minimize downtime. They are a crucial part of effective chemical handling.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 6mm 13mm 19mm Inert Alumina Ceramic Media Alumina Inert Ball for Catalyst Support Media

What are alumina inert ceramic balls?

These balls are made from high-quality alumina. They act as support media for catalysts in chemical reactors. They provide a stable base for catalysts. They keep catalyst beds working well.

What sizes do you offer?

We supply three main sizes: 6mm, 13mm, and 19mm. The size you pick depends on your reactor design. It also depends on your specific catalyst requirements. Larger balls offer lower pressure drop. Smaller balls give more surface contact.

How hot can they get?

These balls handle extreme heat very well. They work fine in temperatures up to 1650°C (3000°F). This makes them perfect for demanding processes. Examples include oil refining and petrochemical production.

Do they resist chemicals?

Yes, they are very chemically inert. They resist strong acids and strong alkalis. They also resist corrosion from solvents. This stability ensures long life. It prevents contamination of your process.

Why choose alumina over cheaper options?

Alumina balls are much harder and stronger than alternatives like silica. They resist crushing and wear much better. This means they last longer. You avoid costly shutdowns for media replacement. Their performance justifies the investment.

(6mm 13mm 19mm Inert Alumina Ceramic Media Alumina Inert Ball for Catalyst Support Media)

REQUEST A QUOTE

RELATED PRODUCTS

92% Alumina Ceramic Grinding Balls for Industrial Use

20 kg of Bulk High Temperatureceramic Ball Alumina Ceramic Ball

Alumina Resistant Wearable Fire Brick Firebrick Wood Ceramic Refractory Ceramic Ball for Oven

Best Alumina Ceramic Ball Corundum Refractory Material Whole Refractory Ball

92% 95% Alumina Ceramic Balls for Grinding