Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

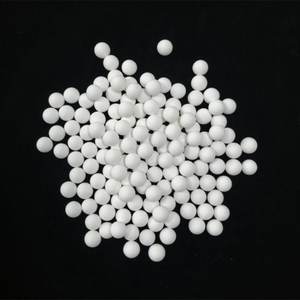

Overview of 92% 95%alumina Ceramic Grinding Media Balls Creamic Ball Inert Ceramic Alumina Ball for Chemical Industry

Alumina balls are high-purity ceramic grinding media known for their exceptional hardness, wear resistance, and thermal stability. Ideal for industrial applications like milling, catalysis, and wear-resistant components.

Features of 92% 95%alumina Ceramic Grinding Media Balls Creamic Ball Inert Ceramic Alumina Ball for Chemical Industry

High mechanical strength & durability

Excellent chemical & thermal stability

Superior wear & corrosion resistance

Available in various sizes & purity grades

Low contamination for precision processes

(92% 95%alumina Ceramic Grinding Media Balls Creamic Ball Inert Ceramic Alumina Ball for Chemical Industry)

Specification of 92% 95%alumina Ceramic Grinding Media Balls Creamic Ball Inert Ceramic Alumina Ball for Chemical Industry

These alumina ceramic grinding media balls are created for grinding jobs. They are made from high-purity alumina. Common qualities are 92% and 95% alumina content. The remaining material helps bind the ceramic together. This creates an incredibly hard and dense grinding ball.

They use remarkable hardness. This solidity measures around 9 on the Mohs range. It approaches the solidity of diamonds. High thickness is one more crucial function. Density typically ranges from 3.6 to 3.7 grams per cubic centimeter. This thickness provides considerable grinding impact. The spheres are likewise really put on immune. This wear resistance indicates they last a lot longer than steel rounds. They shed extremely little weight during grinding procedures.

Chemical stability is important for the chemical sector. These alumina rounds succeed right here. They withstand assault from solid acids and strong alkalis. They function well in corrosive atmospheres. Their inert nature prevents contamination. They won’t react with the products being processed. This makes sure item pureness.

The spheres have low water absorption. Water absorption is much less than 0.1%. This avoids swelling or compromising. They maintain regular shapes and size. High compressive strength is essential. It enables the balls to handle heavy grinding loads. They hold up against considerable stress without damaging.

These residential properties make them ideal for several demanding applications. They are made use of in round mills and attritors. They grind materials like minerals, ceramics, and chemicals. They are excellent for generating pigments, dyes, and advanced porcelains. The chemical sector depends on them for regular fragment size decrease. They give effective grinding with very little contamination. Selecting in between 92% and 95% alumina depends upon particular demands. Higher purity generally provides better wear resistance and chemical security. It might set you back a bit much more.

(92% 95%alumina Ceramic Grinding Media Balls Creamic Ball Inert Ceramic Alumina Ball for Chemical Industry)

Applications of 92% 95%alumina Ceramic Grinding Media Balls Creamic Ball Inert Ceramic Alumina Ball for Chemical Industry

Alumina ceramic grinding media balls are vital devices in the chemical sector. These spheres are made from high-purity material. Normally they have 92% or 95% alumina. This makes them incredibly difficult and sturdy. They stand up to put on extremely well. This lengthy life decreases substitute prices dramatically. Chemical resistance is one more major benefit. These balls endure rough acids, strong alkalis, and corrosive solvents. They do not react with the materials being processed. This inertness is essential. It stops contamination of sensitive chemical products. Product pureness is necessary for top quality.

These ceramic rounds master grinding and milling applications. They crush and blend strong materials effectively. They are perfect for processing pigments and dyes. Uniform shade distribution is attained. They function well for grinding minerals and chemical powders. Fine fragment dimensions are produced consistently. They are ideal for usage inside round mills and attritors. The balls roll and affect materials successfully. This action breaks down bits extensively.

Chemical plants utilize these rounds in many procedures. They grind catalysts for chemical reactions. They mill raw materials prior to further processing. They mix compounds in suspension. They aid spread solids in fluids. They refine unpleasant slurries properly. Their solidity protects against damaging. They preserve their round shape over time. This makes sure regular grinding performance. Smooth operation of devices outcomes. Maintenance downtime decreases. Energy performance usually enhances as well. These rounds are reputable workhorses. They take care of challenging chemical settings daily. Their performance equates right into price savings. Chemical manufacturers value their dependability.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 92% 95%alumina Ceramic Grinding Media Balls Creamic Ball Inert Ceramic Alumina Ball for Chemical Industry

What are these grinding balls made of?

They are alumina ceramic balls. The main material is aluminum oxide. Two grades exist: 92% alumina and 95% alumina. The 95% version offers higher purity. This means better performance for demanding tasks.

Why is density important?

Density affects grinding efficiency. Higher density balls hit harder. They grind materials faster. The 95% alumina balls are denser than the 92% balls. Choose 95% for tougher grinding jobs needing more impact force.

Will chemicals damage these balls?

No. These balls resist chemicals very well. Acids and alkalis won’t harm them. This makes them perfect for the chemical industry. They handle harsh chemical environments safely. They don’t corrode or contaminate your materials.

Can they handle high heat?

Yes. Alumina ceramic balls withstand extreme temperatures. They work fine in very hot processes. They keep their strength and hardness. This thermal stability is crucial for many industrial applications. They won’t crack or weaken under heat.

What’s the benefit of the ball shape?

The ball shape rolls freely. This ensures even grinding and mixing. It minimizes wear on the balls themselves. It also reduces wear on your grinding equipment. The smooth surface prevents material buildup. It keeps the grinding process efficient.

(92% 95%alumina Ceramic Grinding Media Balls Creamic Ball Inert Ceramic Alumina Ball for Chemical Industry)

REQUEST A QUOTE

RELATED PRODUCTS

20mm 30mm 40mm 50mm High Alumina Catalyst Alumina Grinding Ceramic Ball 95% Purity Alumina Ceramic Grinding Media Ball

Factory Zibo Grinding Media 92% Aluminum Oxide Al2O3 Alumina Ceramic Balls for Ball Mill

3mm 6mm 13mm 19mm 25mm 50mm 60mm 92% 95% 99% Inert Ceramic Ball,Alumina Ball

Inert Alumina Ceramic Packing Ball Porcelain Ball For Support Media 17-23% 92% 99% 3mm 6mm 10mm 13mm 19mm 25mm 30mm 38mm

Porcelain 99–99.7% High Alumina Ceramic Ball Mill Grinding Jar with Lid