Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

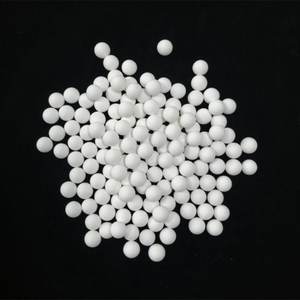

Overview of 92% Alumina Ceramic Grinding Balls for Industrial Use

Alumina balls are high-purity ceramic grinding media known for their exceptional hardness, wear resistance, and thermal stability. Ideal for industrial applications like milling, catalysis, and wear-resistant components.

Features of 92% Alumina Ceramic Grinding Balls for Industrial Use

High mechanical strength & durability

Excellent chemical & thermal stability

Superior wear & corrosion resistance

Available in various sizes & purity grades

Low contamination for precision processes

(92% Alumina Ceramic Grinding Balls for Industrial Use)

Specification of 92% Alumina Ceramic Grinding Balls for Industrial Use

These 92% alumina ceramic grinding spheres are constructed difficult for demanding industrial grinding jobs. They offer a dependable remedy for milling various materials. The key component is alumina, comprising 92% of the round. This high alumina material provides exceptional hardness and use resistance. They last a lot longer than numerous various other grinding media alternatives. This conserves money on substitutes and decreases device downtime.

The rounds are very dense and strong. Their density is normally around 3.60 g/cm FIVE. This high thickness offers exceptional grinding effectiveness. They move energy effectively to the product being ground. You get finer fragment sizes faster. Their hardness actions around 9 on the Mohs scale. This extreme solidity makes them strong versus abrasion. They keep their form well throughout long grinding cycles. This makes sure consistent grinding efficiency with time.

These balls withstand chemical assault properly. They manage acids and alkalis well. This makes them suitable for damp grinding procedures including chemical slurries. They are likewise non-magnetic and non-conductive. This is vital for applications where metal contamination is inappropriate. Industries like electronics and fine chemicals rely upon this purity.

You discover these alumina rounds striving in several locations. They grind raw materials in ceramic manufacturing facilities. They mill lusters and pigments requiring pure outcomes. They refine minerals in mining procedures. They improve powders in advanced products manufacturing. They also operate in paints and layers where shade contamination issues. Their smooth surface reduces bit embedding. This keeps your product tidy. They operate accurately in round mills, vibratory mills, and attritors. They deal with high-impact grinding without damaging apart.

(92% Alumina Ceramic Grinding Balls for Industrial Use)

Applications of 92% Alumina Ceramic Grinding Balls for Industrial Use

92% alumina ceramic grinding spheres are essential devices for many industries. They are made from really hard, dense ceramic material. This makes them outstanding for grinding jobs. Their firmness is a vital benefit. Tough spheres grind products much faster and much more effectively. They lower grinding time and conserve energy. This helps companies lower their operating expense.

These balls are unbelievably resistant to wear. They last a lot longer than steel spheres. They do not chip or break quickly during hard grinding. This means much less downtime for replacing worn balls. Less upkeep is required. Manufacturing facilities avoid frequent closures. Production stays consistent.

Chemical stability is another major benefit. Alumina ceramic rounds don’t respond with a lot of materials. They withstand acids and alkalis well. This makes them perfect for grinding chemicals, dyes, and glazes. They keep the item pure. Contamination from used grinding media is lessened. This is essential for premium results in paints, finishes, and electronic devices.

Mining and minerals processing depend on these balls. They grind ores finely. Their durability takes care of difficult minerals without including unwanted metals. Concrete plants utilize them for grinding basic materials and clinker. They enhance cement fineness. The paint and ink sector advantages as well. These balls grind pigments smoothly. They produce regular, bright shades. Drug firms utilize them for grinding active components. Their inert nature ensures medication purity.

These spheres are additionally really thick. High thickness gives them influence force. This force breaks down products efficiently. They function well in different grinding mills. Ball mills, attritors, and vibratory mills all utilize them. Their regular size and shape provide consistent grinding results. They develop great, even bits. This is necessary for lots of completed items. Their efficiency provides clear benefits over older steel grinding media. They are a wise choice for demanding industrial grinding.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 92% Alumina Ceramic Grinding Balls for Industrial Use

Customers often ask about 92% alumina ceramic grinding balls. Here are common questions and answers.

What sizes do your 92% alumina balls come in?

We offer many sizes. Common diameters are 5mm, 10mm, 15mm, 20mm, 25mm, 30mm, 40mm, and 50mm. Other sizes are possible. Tell us your specific needs. We can usually meet them.

Why pick ceramic balls over steel balls?

Ceramic balls are much harder than steel. They resist wear far better. This means less contamination in your ground material. They last much longer than steel balls too. They save you money over time. They also resist acids and alkalis well. Steel balls rust and corrode.

What industries use these grinding balls?

These balls work in many industries. They grind minerals in mining. They process ceramics and glaze materials. They mix chemicals and pigments. They are vital in paint and coating production. They prepare electronic materials. They are used wherever fine, clean grinding is needed.

Are these balls fragile? How careful must we be?

Alumina ceramic is very hard. It is also brittle. Handle the balls carefully. Avoid dropping them onto hard surfaces from height. Use them correctly inside the mill. They perform well under normal grinding forces. Follow proper loading and operating procedures. This prevents breakage.

How long will these grinding balls last?

Lifespan depends on your specific use. Factors include the material being ground, mill type, operating speed, and filling level. Generally, they last many times longer than steel balls. Their high wear resistance is the reason. Expect significantly reduced replacement frequency. This lowers your operating costs.

(92% Alumina Ceramic Grinding Balls for Industrial Use)

REQUEST A QUOTE

RELATED PRODUCTS

Eco-Friendly Alumina Perforated Ceramic Balls for Long-Lasting Industrial Packing

Alumina Ceramic Ball for Grinding Powder for Grinding Alumina Zirconia Silicate Feldspar Quartz Kaolim Clay

F High Wear-Resistant Alumina Grinding Balls Ceramic Media Balls for Ceramics for Refractory Custom Cutting Bending Welding

92% 95% Alumina Grinding Ball Creamic Ceramic Sintered Bead 0.5-120mm Diameter for Industrial Ceramic Applications

High Quality Ceramic Ball 3-50mm Ceramic Ball Inert Alumina Ceramic Balls For Widely Used In Petroleum