Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

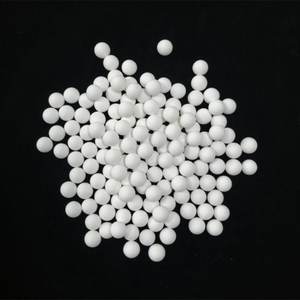

Overview of 96% 5mm Alumina Ceramic Balls for Grinding Media High Wear Resistance

Alumina balls are high-purity ceramic grinding media known for their exceptional hardness, wear resistance, and thermal stability. Ideal for industrial applications like milling, catalysis, and wear-resistant components.

Features of 96% 5mm Alumina Ceramic Balls for Grinding Media High Wear Resistance

High mechanical strength & durability

Excellent chemical & thermal stability

Superior wear & corrosion resistance

Available in various sizes & purity grades

Low contamination for precision processes

(96% 5mm Alumina Ceramic Balls for Grinding Media High Wear Resistance)

Specification of 96% 5mm Alumina Ceramic Balls for Grinding Media High Wear Resistance

These 96% alumina ceramic spheres gauge exactly 5mm in diameter. They are crafted especially for requiring grinding tasks. Their high pureness is essential. This pureness means they are unbelievably tough. They resist put on remarkably well. They last a lot longer than lower-grade choices. This reduces just how usually you require to replace your grinding media. You conserve money gradually.

They work well in sphere mills. They are optimal for grinding paints, chemicals, and minerals. They won’t pollute your products. Alumina balls are chemically inert. They remain steady also under extreme problems. They deal with heats without damaging down. They additionally withstand strong acids and antacid efficiently.

Their surface is incredibly smooth. This lessens rubbing throughout grinding. Much less rubbing indicates less warmth builds up. This safeguards your useful materials. It also prevents undesirable chain reaction. You obtain a consistent, fine work every time. They are much denser than steel rounds. This density equates to powerful grinding impact. They damage down fragments successfully.

These spheres offer superior efficiency. They outperform steel or glass grains substantially. Steel grains wear down swiftly. They can additionally rust and contaminate your item. Glass grains damage conveniently. They create fragments that wreck your batch. Alumina rounds prevent these troubles completely. They preserve their integrity run after run. They maintain your grinding procedure dependable. You experience less unexpected quits. Your production remains on timetable. Downtime costs cash. Using these spheres aids avoid that.

They are very challenging. They resist chipping and fracturing. Impact damages is uncommon. This durability originates from the high alumina content. The production procedure makes certain uniform quality. Every ball satisfies rigorous specifications. Dimension consistency is essential for even grinding. These balls supply that consistency. You achieve uniform cause your end product. This quality matters for numerous sectors. Uniformity builds trust with your clients.

Their high wear resistance is their greatest advantage. They shed really little product during use. This suggests your ground item remains cleaner. Much less media particles mixes in. You get a purer end result. Maintenance ends up being simpler also. You inspect and change media much less usually. Labor prices decrease. General operating effectiveness boosts.

(96% 5mm Alumina Ceramic Balls for Grinding Media High Wear Resistance)

Applications of 96% 5mm Alumina Ceramic Balls for Grinding Media High Wear Resistance

These 96% alumina ceramic balls are 5mm in size. They are made for grinding jobs. Their high pureness makes them really hard. This hardness gives them excellent wear resistance. That suggests they last a long time in tough grinding machines.

The 96% alumina content is very important. It makes the rounds a lot stronger than reduced pureness choices. They resist damaging much better. This decreases just how usually you require to replace them. It conserves cash and maker downtime. High purity also indicates really low chemical contamination. Your ground materials remain pure. This is important for items like paints, layers, and electronics powders.

The 5mm size is extremely helpful. It fits lots of typical grinding mills perfectly. Small balls create a huge surface area for grinding. This makes the grinding process quicker and much more effective. You get better bit sizes regularly. This size is prominent for grinding pigments, minerals, and chemicals.

Wear resistance is their most significant benefit. They are much more challenging than steel balls. They don’t wear down promptly. This suggests much less product from the balls obtains blended right into your product. Your final product top quality remains high. Much less use additionally indicates you need to add less new rounds over time. Your grinding process remains steady longer.

These balls work well in several industries. Utilize them for grinding glazes and ceramic powders. They are good for grating minerals and steel powders. They master preparing paints and printing inks. Drug business use them for energetic ingredients. Chemical plants depend on them for grinding catalysts and various other delicate products. They deal with damp and completely dry grinding processes effectively.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 96% 5mm Alumina Ceramic Balls for Grinding Media High Wear Resistance

Here are five common questions about our 96% purity 5mm Alumina Ceramic Balls for grinding media:

What makes these alumina balls good for grinding? They are extremely hard. Their hardness is near the top of the Mohs scale. This hardness lets them crush materials effectively. They resist wear exceptionally well. This means they last much longer than softer grinding media. You save money over time because you replace them less often.

How long will these ceramic balls last? Their wear resistance is very high. They lose material very slowly during grinding. This slow wear rate extends their usable life significantly. Compared to steel balls or lower quality ceramics, they outlast them by a wide margin. They withstand constant impact and friction better.

Is the 96% alumina purity important? Yes, purity matters a lot. Higher purity alumina means better performance. Our 96% grade offers excellent hardness and wear resistance. It balances cost and effectiveness perfectly. Lower purity balls might be cheaper initially. They wear out much faster. You end up paying more long-term.

Why is the 5mm size common? The 5mm size works well for many grinding jobs. It is small enough for efficient grinding action. It is large enough to handle without difficulty. This size suits many types of mills and materials. Other sizes are available. The 5mm is a popular, versatile choice.

What materials can I grind with these balls? They grind many hard materials well. Common uses include grinding minerals, ceramics, and chemicals. They work in paints, coatings, and electronic materials. They are chemically inert. They won’t contaminate your product. They handle wet or dry grinding processes effectively.

(96% 5mm Alumina Ceramic Balls for Grinding Media High Wear Resistance)

REQUEST A QUOTE

RELATED PRODUCTS

High Alumina Ceramic Balls 5mm 8mm 10mm 15mm 31mm 52mm 99% Al2O3 Support Media Alumina Ball

Industrial Wear-Resistant Alumina Ceramic Ball Media White Inert Ceramic Alumina Processing Services Welding Cutting Bending

3-5mm Defluorinating Activated Alumina Ball Alumina Desiccant Ball

Whole High Precision Polishing White Alumina Balls Ceramic Deburring Grinding Media for Metal and Glass

Support Media Alumina Ceramic Ball Al2O3 13-27% Inert Ceramic Ball 3mm 6mm 10mm 16mm 25mm