Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

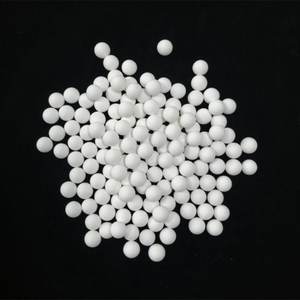

Overview of Ceramic Ball High Crush Strength Support Media Industry 92% Ceramic Alumina Ball

Alumina balls are high-purity ceramic grinding media known for their exceptional hardness, wear resistance, and thermal stability. Ideal for industrial applications like milling, catalysis, and wear-resistant components.

Features of Ceramic Ball High Crush Strength Support Media Industry 92% Ceramic Alumina Ball

High mechanical strength & durability

Excellent chemical & thermal stability

Superior wear & corrosion resistance

Available in various sizes & purity grades

Low contamination for precision processes

(Ceramic Ball High Crush Strength Support Media Industry 92% Ceramic Alumina Ball)

Specification of Ceramic Ball High Crush Strength Support Media Industry 92% Ceramic Alumina Ball

Right here’s the item description for the 92% Ceramic Alumina Ball with high crush stamina. These rounds are assistance media for hard commercial tasks. They are extremely strong. They withstand squashing under heavy tons. This toughness is crucial for jam-packed beds and towers. These frameworks require reliable support.

The balls are made from 92% alumina ceramic. This product is extremely difficult. It offers outstanding wear resistance. The spheres last a long time. They endure constant friction and pressure. This reduces substitute frequency. This saves cash with time.

Chemical resistance is another significant benefit. The rounds manage corrosive atmospheres well. They stand up to acids, antacid, and solvents. This makes them risk-free for chemical processing. They are additionally secure for water therapy systems. Thermal security is high. The rounds carry out in severe heat. They are suitable for high-temperature applications. They preserve integrity without breaking.

Their shape is perfectly round. This makes certain also packing thickness. It promotes uniform circulation circulation. This is crucial for effective procedures. It protects against directing or clogs. Constant circulation enhances general system efficiency. The surface area is very smooth. This decreases friction loss. It helps reduce power consumption.

Sizes are offered from 3mm to 50mm. This array fits various column sizes. It fits various process demands. The balls offer inert assistance. They do not respond with procedure materials. They shield delicate drivers or resins below. They are the foundation for trusted procedures. They provide dependable performance day after day. They are a cost-efficient service for demanding industries.

(Ceramic Ball High Crush Strength Support Media Industry 92% Ceramic Alumina Ball)

Applications of Ceramic Ball High Crush Strength Support Media Industry 92% Ceramic Alumina Ball

These ceramic alumina rounds are tough. They are 92% alumina. This high purity makes them extremely hard. They resist crushing under hefty tons. Individuals utilize them as support media in lots of markets. They hold driver materials in place inside reactors. They stop great driver fragments from relocating or clogging. This keeps chemical procedures running smoothly.

Their toughness is crucial. They take care of the weight of driver beds quickly. They also stand up to high pressure inside vessels. They don’t damage or collapse. This implies longer life for the support layer. Fewer closures are needed for replacements. This saves time and money.

Chemical resistance is an additional vital function. These balls won’t react with many chemicals. They function well in extreme environments. Acids and antacids don’t harm them. High temperatures are additionally no worry. They stay secure under intense warm. This makes them perfect for demanding procedures.

You discover them in oil refineries and chemical plants. They support drivers in reactors making gas and plastics. The gas market relies upon them. They are crucial in gas purification towers. Fertilizer production uses them too. They support catalysts in ammonia synthesis devices.

Water treatment centers use these spheres. They act as support media in large filter beds. They help disperse water circulation evenly. They give a strong base for filtering system products. Their inert nature makes certain clean water outcome.

Their size and shape correspond. This permits even packing inside towers. It creates uniform circulation courses for gases or liquids. It avoids directing or irregular circulation. Consistent flow boosts procedure efficiency. It also aids maximize stimulant efficiency.

These rounds provide dependable, durable support. They sustain hard problems every year. Their high crush toughness is shown in real-world use. They are a functional choice for sturdy industrial applications. They keep vital processes running reliably.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Ceramic Ball High Crush Strength Support Media Industry 92% Ceramic Alumina Ball

What makes these ceramic balls strong?

They use 92% alumina. This high-grade material gets fired at extreme heat. That process creates a dense, hard structure. This density gives the balls their high crush strength. They handle heavy loads without breaking.

How hot can they get?

These balls resist very high temperatures. They work fine in environments exceeding 1000°C. They don’t crack or weaken under intense heat. This makes them reliable for demanding processes.

What sizes are available?

We offer many sizes. Common diameters range from 3mm to 50mm. Other sizes are possible too. Tell us your needs. We can likely supply the right size for your equipment.

Why use 92% alumina?

92% alumina offers the best balance. It provides excellent strength and durability. It resists chemical attack well. It costs less than higher purity options like 99% alumina. This makes it a practical, cost-effective choice for tough jobs.

Where are they used?

These balls are support media. They go inside reactors, towers, and dryers. They hold up catalyst pellets or other materials. They let gases or liquids flow through freely. You find them in oil refining, chemical plants, and environmental systems. They provide strong, stable support.

(Ceramic Ball High Crush Strength Support Media Industry 92% Ceramic Alumina Ball)

REQUEST A QUOTE

RELATED PRODUCTS

High-Purity Alumina Ceramic Ball Valve Core Wear-Resistant for Industrial Applications

92% Alumina Ceramic Grinding Ball

60% 70% 92% 95% 99% Alumina Ceramic Balls 30mm 50mm High Alumina Grinding Ball for Grinding Machine

Competitive High Efficient Activated Alumina Ceramic Ball Desiccant

Cushion Filler Polishing Custom Bio Alumina Ceramic Balls Alkaline Mineral Purification Water Filter Media Shower Ball Decor