Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

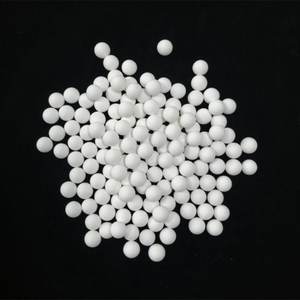

Overview of Diameter Size 2mm 19mm 20mm 30mm Grinding Media Alumina Ceramic Balls

Alumina balls are high-purity ceramic grinding media known for their exceptional hardness, wear resistance, and thermal stability. Ideal for industrial applications like milling, catalysis, and wear-resistant components.

Features of Diameter Size 2mm 19mm 20mm 30mm Grinding Media Alumina Ceramic Balls

High mechanical strength & durability

Excellent chemical & thermal stability

Superior wear & corrosion resistance

Available in various sizes & purity grades

Low contamination for precision processes

(Diameter Size 2mm 19mm 20mm 30mm Grinding Media Alumina Ceramic Balls)

Specification of Diameter Size 2mm 19mm 20mm 30mm Grinding Media Alumina Ceramic Balls

These alumina ceramic grinding media balls come in precise diameters: 2mm, 19mm, 20mm, and 30mm. They are designed for grinding and milling applications. The material is high-purity aluminum oxide. This makes them incredibly hard. They resist wear very well. This wear resistance is crucial. It means the balls last much longer than other materials. You won’t need to replace them as often.

The balls have a high density. Density relates directly to grinding efficiency. Dense balls transfer impact energy better. This results in faster material size reduction. It improves your grinding process speed. You get finer particles more quickly.

Chemical stability is another major benefit. Alumina ceramic balls resist acids and alkalis. They won’t corrode or degrade in harsh environments. This makes them safe for processing many chemicals. They are also non-contaminating. They won’t add impurities to your product. This purity is essential for industries like food, pharmaceuticals, and electronics.

These balls handle high temperatures easily. Thermal shock resistance is good. They won’t crack from sudden temperature changes. This is important in processes involving heat.

The surface of these balls is very smooth. This minimizes friction during grinding. It also reduces wear on your mill liners. Lower friction means less energy consumption. You save on operating costs.

Sizes like 2mm are ideal for ultra-fine grinding. Larger sizes like 19mm, 20mm, and 30mm suit bigger milling tasks. They provide significant impact force. You can choose the exact size needed for your specific equipment and material. Consistent size ensures even grinding performance. All balls within a batch are uniform. This avoids process inefficiencies. Custom sizes are often available too. You get the right ball for your job.

These alumina balls offer a reliable grinding solution. They deliver high performance and long life. They reduce downtime and maintenance costs.

(Diameter Size 2mm 19mm 20mm 30mm Grinding Media Alumina Ceramic Balls)

Applications of Diameter Size 2mm 19mm 20mm 30mm Grinding Media Alumina Ceramic Balls

Alumina ceramic grinding balls come in many sizes. Different sizes suit different grinding jobs. These balls are very hard. They resist wear extremely well. They last a long time in tough conditions. Chemical stability is another key benefit. They work well with acids, bases, and solvents. They won’t contaminate your materials. This makes them perfect for many industries.

Small 2mm balls handle fine grinding tasks. They work inside bead mills and attritors. You find them grinding paints, inks, and coatings. They grind electronic ceramics and pigments too. They create very smooth, fine particle sizes.

Larger balls like 19mm and 20mm tackle bigger jobs. They are common in ball mills. Mining operations use them to grind ores. The cement industry relies on them for grinding clinker. They are good for minerals and chemicals also. These sizes offer a strong impact force. They break down materials effectively.

The biggest 30mm balls deliver maximum impact. They are for primary grinding stages. They start the size reduction process. Heavy industries use them first. They break large chunks of raw material. They prepare material for finer grinding later. This size handles the initial heavy work.

These alumina balls save money over time. They outlast steel balls significantly. They cut down on replacement frequency. They reduce machine downtime. Energy efficiency improves too. They require less power for grinding. Consistent performance is guaranteed. They keep your product quality high. Choose the right size for your specific grinding need.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Diameter Size 2mm 19mm 20mm 30mm Grinding Media Alumina Ceramic Balls

What are alumina ceramic balls made from?

These grinding balls use high-purity aluminum oxide. This material is extremely hard. It resists wear very well. It handles high temperatures effectively. Chemical corrosion rarely affects it. This makes them reliable for tough grinding jobs.

Why offer sizes like 2mm, 19mm, 20mm, and 30mm?

Different grinding tasks need different ball sizes. Small 2mm balls are for ultra-fine grinding. They work well in paints or electronic materials. Medium sizes like 19mm and 20mm suit general milling. Large 30mm balls deliver heavy impact force. They are ideal for breaking down coarse materials in mining or cement.

Why choose alumina balls over steel balls?

Alumina balls last much longer. They resist wear better than steel. This reduces replacement costs. They generate less heat during grinding. They prevent iron contamination. This is vital for food, pharmaceuticals, and chemicals. They are also lighter. This saves energy in mills.

Where are these specific sizes used?

Use 2mm balls for fine pigments, inks, or electronic powders. Choose 19mm or 20mm balls for minerals, ceramics, or base metal powders. Opt for 30mm balls in large ball mills. They grind cement clinker or ores effectively. The size matches the material’s starting size.

What are the main benefits?

Alumina balls offer high hardness. They resist abrasion exceptionally well. This extends their service life significantly. They maintain product purity. No metal contamination occurs. They operate efficiently. Lower density reduces energy use. They endure harsh chemical environments. Their consistent shape ensures even grinding performance.

(Diameter Size 2mm 19mm 20mm 30mm Grinding Media Alumina Ceramic Balls)

REQUEST A QUOTE

RELATED PRODUCTS

92% 95% Alumina Ceramic Balls for Grinding

High Quality 3.6.8.10.13.16.20mm Inert Ceramic Balls Inert Alumina Ceramic Ball Packing Ball

High Alumina 99 Al2O3 Ceramic Balls Alumina Ceramic Beads 1-80mm

Whole Bubble Alumina/refractory Ceramic Hollow Ball /Alumina Hollow Sphere

Cushion Filler Polishing Custom Bio Alumina Ceramic Balls Alkaline Mineral Purification Water Filter Media Shower Ball Decor