Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

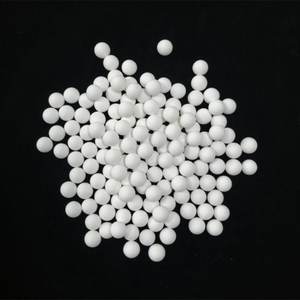

Overview of Factory 3mm~50mm Inert Alumina Ball for Petroleum Industry

Alumina balls are high-purity ceramic grinding media known for their exceptional hardness, wear resistance, and thermal stability. Ideal for industrial applications like milling, catalysis, and wear-resistant components.

Features of Factory 3mm~50mm Inert Alumina Ball for Petroleum Industry

High mechanical strength & durability

Excellent chemical & thermal stability

Superior wear & corrosion resistance

Available in various sizes & purity grades

Low contamination for precision processes

(Factory 3mm~50mm Inert Alumina Ball for Petroleum Industry)

Specification of Factory 3mm~50mm Inert Alumina Ball for Petroleum Industry

These inert alumina spheres offer oil handling devices. They can be found in sizes from 3mm to 50mm. This broad size range fits various reactor requirements. Small balls provide even more area. Big balls assist control gas flow.

The balls are made from high-purity alumina. This material is extremely difficult. It holds up against severe pressure inside reactors. The spheres won’t break quickly. They keep their form under hefty lots. This is vital for secure procedure.

Chemical resistance is excellent. Alumina doesn’t react with many hydrocarbons or processing chemicals. It remains inert. This protects against contamination of beneficial items. Activator performance remains constant.

The rounds manage really high temperatures. They function well over 1000 ° C. Thermal shock resistance is excellent. Unexpected temperature level adjustments will not fracture them. This guarantees lengthy life span in demanding problems.

Surface area smoothness is managed. This reduces dirt generation. Less dust implies much less devices wear. Item pureness is also safeguarded. The rounds are evenly round. This makes certain even packing in reactors. Gas or fluid flows equally with the bed.

High thickness offers the balls good weight. They stay put in activators. Liquid circulation does not dislodge them easily. Packing density is optimized. This makes the most of effectiveness in the activator room. Mass density is about 1.4 g/cm FOUR.

These alumina rounds support driver beds. They different stimulant layers. They act as inert filler product. Their job is to distribute liquids uniformly. They likewise shield fragile stimulant fragments. Requirement packaging makes use of 25kg bags or 1-ton super sacks. Moisture-proof product packaging avoids damage during shipping.

(Factory 3mm~50mm Inert Alumina Ball for Petroleum Industry)

Applications of Factory 3mm~50mm Inert Alumina Ball for Petroleum Industry

These 3mm to 50mm inert alumina rounds offer important roles in oil refineries. They function as strong, reliable support for valuable drivers. Catalysts drive essential chemical reactions. These balls hold stimulants in place inside reactors. They manage extreme heat and pressure. This protects against catalyst damages and makes sure smooth gas circulation.

Refineries use them heavily in hydrotreating units. Hydrotreating removes damaging sulfur and nitrogen from gas. The alumina rounds create a stable bed for the stimulants. They additionally help spread the oil and hydrogen equally. This makes the cleaning process job much better. Similar arrangements occur in hydrocracking devices. Hydrocracking breaks heavy oil into lighter, valuable products. Once more, the balls support the splitting catalysts efficiently.

An additional key task remains in guard beds. Feedstocks getting in reactors commonly contain destructive contaminations. These include metals and great fragments. Guard beds filled with alumina spheres catch these impurities. They secure the delicate, expensive drivers downstream. This conserves money and prevents costly closures. The balls’ firmness and chemical resistance are ideal for this dirty work.

Their high pureness is critical. Pollutants can seep out and poison the process. Their constant size ensures even packing. This prevents funneling and irregular circulation. Excellent circulation is important for reliable reactions. These rounds withstand years of challenging service. They stand up to wear and thermal shock. This toughness implies less downtime and lower prices. Oil refineries rely upon their reliable efficiency daily.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Factory 3mm~50mm Inert Alumina Ball for Petroleum Industry

What exactly are these alumina balls made of?

They are pure ceramic balls. They come from industrial alumina. They undergo high-temperature treatment. This makes them very hard. They become chemically inactive. They resist strong acids. They resist strong alkalis too. They do not react with petroleum products. They stay stable inside reactors.

Why choose 3mm balls over 50mm balls?

Size matters for different jobs. Small 3mm balls create a tight bed. They offer huge surface area. This is good for guarding catalysts. They stop fine catalyst dust. They prevent clogging below. Large 50mm balls handle heavy loads. They support catalyst layers well. They withstand big pressure drops. They are ideal for large reactors. They distribute gas or liquid evenly.

Can these balls handle extreme heat?

Yes, they handle high heat well. They are rated for 1650°C. They work fine under 1400°C. This covers most refinery processes. They resist thermal shock too. They won’t crack easily. They survive sudden temperature changes. They are reliable for heaters and reformers.

How long do they last before needing replacement?

They last many years typically. They are very tough. They resist wear and tear. Actual life depends on conditions. Check them yearly. Look for severe chipping. Look for surface powdering. Replace them if these signs appear. Good care extends their life.

Are they a cost-effective solution?

Yes, they offer good value. Their upfront cost is reasonable. Their long life reduces replacement costs. They protect expensive catalysts. They prevent reactor shutdowns. They cut maintenance expenses. They save money over time. They are a smart investment.

(Factory 3mm~50mm Inert Alumina Ball for Petroleum Industry)

REQUEST A QUOTE

RELATED PRODUCTS

Wear Resistant ZrO2 Zirconia Alumina Ceramic Grinding Media Ball Beads

High Quality Ceramic Ball Alumina Ball for Ceramic

95% Heat Storage Ceramic Refractory Ball High Alumina Corundum Refractory Ball for Industry

23% AL2O3 Inert Alumina Ceramic Ball Industrial Ceramic Catalyst Support Media for Cutting Process

High Strength Corundum Alumina Ceramic Ball 1-5mm Used Furnace Refractory Balls For Industry Kiln Made MGO Alumina Cement SIO2