Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

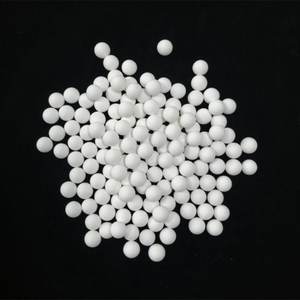

Overview of Factory Zibo Grinding Media 92% Aluminum Oxide Al2O3 Alumina Ceramic Balls for Ball Mill

Alumina balls are high-purity ceramic grinding media known for their exceptional hardness, wear resistance, and thermal stability. Ideal for industrial applications like milling, catalysis, and wear-resistant components.

Features of Factory Zibo Grinding Media 92% Aluminum Oxide Al2O3 Alumina Ceramic Balls for Ball Mill

High mechanical strength & durability

Excellent chemical & thermal stability

Superior wear & corrosion resistance

Available in various sizes & purity grades

Low contamination for precision processes

(Factory Zibo Grinding Media 92% Aluminum Oxide Al2O3 Alumina Ceramic Balls for Ball Mill)

Specification of Factory Zibo Grinding Media 92% Aluminum Oxide Al2O3 Alumina Ceramic Balls for Ball Mill

Factory Zibo Grinding Media: 92% Aluminum Oxide Alumina Ceramic Balls .

Zibo Grinding Media produces high-grade alumina ceramic rounds. These balls are essential for ball mill procedures. They are made from 92% light weight aluminum oxide (Al2O3). This material ensures exceptional hardness and use resistance.

The rounds come in various dimensions. Common sizes range from 5mm to 50mm. They are ideal for grinding applications. Their consistent shape enhances grinding effectiveness.

These alumina ceramic rounds have high density. They provide superb effect resistance. They appropriate for harsh commercial environments. Their thermal stability is amazing.

They are used in sphere mills. They grind materials like minerals, concrete, and pigments. They are suitable for both damp and dry grinding. Their reduced wear rate minimizes contamination.

Our ceramic spheres flaunt a smooth surface area coating. This reduces rubbing during grinding. It extends the life-span of milling devices.

They are chemically inert. They stand up to acids and alkalis efficiently. They maintain performance in harsh environments.

Production complies with strict quality assurance standards. Each batch undergoes rigorous screening. This guarantees constant performance.

Our grinding media balls are cost-efficient. They offer a longer service life than choices. This decreases replacement frequency.

Select Zibo Grinding Media for reputable grinding solutions. Our alumina ceramic balls enhance your milling effectiveness. They make sure constant results.

Factory Zibo Grinding Media rounds are made to fulfill sector requirements. They are available wholesale amounts. Contact us for customized requirements.

(Factory Zibo Grinding Media 92% Aluminum Oxide Al2O3 Alumina Ceramic Balls for Ball Mill)

Applications of Factory Zibo Grinding Media 92% Aluminum Oxide Al2O3 Alumina Ceramic Balls for Ball Mill

Zibo grinding media offers 92% aluminum oxide (Al2O3) alumina ceramic rounds for sphere mills. These balls are extremely difficult. They resist wear exceptionally well. This makes them last much longer than steel rounds in tough grinding tasks. You get more grinding time prior to requiring substitutes. This saves cash lasting.

These ceramic balls take care of demanding grinding job effectively. They function well grinding minerals in mining. They grind resources for ceramics. They grind powders for paints and finishings. They grind chemicals. They grind various other materials needing great fragments. Their high hardness breaks down materials properly. They maintain consistent efficiency.

Making use of alumina rounds reduces contamination. Steel rounds corrosion. Steel balls use down. This presents steel pollutants into your product. Alumina balls do not corrosion. They put on extremely little. This keeps your ground material cleaner. This pureness issues for premium porcelains. This purity matters for electronics. This purity matters for drugs. Contamination control is much easier.

These rounds are much lighter than steel balls of the exact same dimension. Lighter balls need less energy to turn the mill. You utilize much less electrical power. Your grinding prices decrease. Less power also implies less heat builds up. This shields heat-sensitive products. Your tools runs cooler.

Alumina ceramic balls hold up against corrosion. Acidic slurries damages steel rounds rapidly. Alumina spheres stand up to chemical assault. They function accurately in rough chemical settings. You stay clear of constant shutdowns for maintenance. Manufacturing stays regular.

Manufacturing facility Zibo grinding media offers a reputable option. These 92% Al2O3 rounds enhance grinding performance. They cut functional expenses dramatically. They expand mill liner life. They boost item purity. They supply a strong roi across many sectors. Replacing steel balls saves cash every day.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Factory Zibo Grinding Media 92% Aluminum Oxide Al2O3 Alumina Ceramic Balls for Ball Mill

What are these ceramic balls made from?

They contain 92% aluminum oxide (Al2O3). This material is very hard. It resists wear extremely well. It handles tough grinding conditions reliably. The high alumina content provides these benefits.

What sizes do you offer?

We make balls from 5mm up to 70mm. Common sizes are 10mm, 15mm, 20mm, 25mm, 30mm, 40mm, 50mm, 60mm. You can order the exact size needed. We ensure consistent size and roundness.

Where are these balls typically used?

They work in ball mills grinding many materials. Examples are ceramics, cement, paint, chemicals, minerals. They suit wet and dry grinding processes. They are good for fine grinding tasks.

Why pick alumina balls over steel balls?

Alumina balls are much harder than steel. They last longer. This means less downtime. They save money over time. They also prevent material contamination. Steel balls rust and add iron. Alumina balls keep your product pure. They are also lighter than steel. This reduces energy use sometimes.

How should I use these balls in my mill?

Choose the right size for your material. Load the balls correctly. Follow the mill manufacturer’s guidelines. Check the balls periodically. Replace worn balls. This keeps grinding efficient. Handle them carefully. Avoid dropping them on hard surfaces. This prevents chipping.

(Factory Zibo Grinding Media 92% Aluminum Oxide Al2O3 Alumina Ceramic Balls for Ball Mill)

REQUEST A QUOTE

RELATED PRODUCTS

Ceramics Factory Manufacturing High Strength 92% High Alumina Balls 3mm 6mm 10mm 16mm Inert Ceramic Ball Support Media

Wear Resistance Alumina Ball High Purity 99 Aluminium Oxide Grinding Ceramic Balls

Factory Supply Customized Activated Inert Alumina Ball 92% High Alumina Ceramic Balls Alumina Packing Ball

Factory Desiccant Activated Alumina Ball for Liquid and Gas Drying for Defluoridation Filter Water Alumina Ceramic B

High Quality Ceramic Ball 3-50mm Ceramic Ball Inert Alumina Ceramic Balls For Widely Used In Petroleum