Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

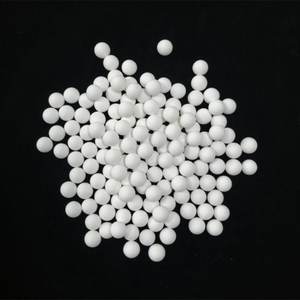

Overview of High Precision 92% Al2O3 Alumina Ceramic Ball for Ball Mill

Alumina balls are high-purity ceramic grinding media known for their exceptional hardness, wear resistance, and thermal stability. Ideal for industrial applications like milling, catalysis, and wear-resistant components.

Features of High Precision 92% Al2O3 Alumina Ceramic Ball for Ball Mill

High mechanical strength & durability

Excellent chemical & thermal stability

Superior wear & corrosion resistance

Available in various sizes & purity grades

Low contamination for precision processes

(High Precision 92% Al2O3 Alumina Ceramic Ball for Ball Mill)

Specification of High Precision 92% Al2O3 Alumina Ceramic Ball for Ball Mill

These high precision alumina ceramic balls are produced ball mill grinding. They include 92% Al2O3. This product gives superb performance. Alumina ceramic rounds are very hard. They stand up to wear exceptionally well. This implies they last a lot longer than various other grinding media. You get even more grinding cycles from them.

Their thickness is high, around 3.65 g/cm ³. This high thickness offers strong influence pressure throughout grinding. It aids crush products effectively. The balls preserve their round shape well. Surface roughness is very low. This reduces contamination of your ground product. Your product stays pure.

Chemical stability is a major benefit. These balls resist acids and alkalis. They work great in harsh settings. They don’t respond with the majority of products. This is very important for chemical handling. Heat resistance is likewise good. They take care of heat well during grinding procedures.

The wear price is extremely low. Anticipate less than 0.5% wear per hour under regular usage. This reduced wear rate lowers costs. You require fewer replacements. Less upkeep is required. Grinding efficiency remains high constantly. Energy intake can be lower as well.

These ceramic rounds are perfect for grinding lots of materials. Use them for minerals, porcelains, paints, and chemicals. They are ideal where pureness matters. They stop iron contamination. This is crucial in electronics or fine porcelains. Their smooth surface area makes sure minimal powder bond. Grinding outcomes are reliable and foreseeable. They supply a dependable option for demanding milling jobs.

(High Precision 92% Al2O3 Alumina Ceramic Ball for Ball Mill)

Applications of High Precision 92% Al2O3 Alumina Ceramic Ball for Ball Mill

High accuracy 92% Al2O3 alumina ceramic rounds are necessary grinding media for ball mills. They supply substantial benefits over traditional steel rounds. Their severe firmness is essential. This solidity makes certain very little wear throughout grinding. Less use suggests the balls last much longer. You need to change them much less frequently. This conserves cash on maintenance and downtime.

Contamination is a significant trouble in several sectors. Alumina ceramic rounds solve this. They are chemically inert. They won’t react with the products being ground. They additionally will not corrosion or corrode. This keeps your product pure. Industries like pharmaceuticals and great chemicals require this purity. Food processing also benefits greatly.

The thickness of these balls is important too. It’s less than steel. This implies less energy is needed to run the mill. You get the exact same grinding power with lower power intake. This cuts your operating expense. The balls are likewise extremely smooth. This smoothness decreases rubbing. Much less rubbing implies a lot more power financial savings.

These ceramic spheres perform extremely well in wet grinding. They stand up to degradation from water and chemicals. This makes them ideal for mineral handling. They are additionally optimal for grinding ceramic powders and pigments. Repaint and finish manufacturers depend on them for consistent color and structure. Their toughness deals with abrasive products properly. Mining operations use them for grinding ores. They keep fragment size control over long periods.

The satiation and dimension uniformity are essential. High accuracy production ensures each round is virtually excellent. This uniform shape leads to effective grinding. It protects against uneven deterioration inside the mill. It additionally makes certain a consistent grinding activity on the material. You get foreseeable results batch after set. Making use of these balls improves your total milling effectiveness. They are a smart financial investment for demanding grinding applications.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Precision 92% Al2O3 Alumina Ceramic Ball for Ball Mill

What are these ceramic balls made of?

They’re 92% alumina ceramic. The rest is other materials binding it together. This mix makes them very hard and tough. They last a long time grinding materials.

Why use them instead of steel balls?

Ceramic balls are much harder than steel. They don’t wear down as fast. Steel balls add metal bits to your ground material. Ceramic balls stay clean. This keeps your final product pure.

Are they good for grinding tough stuff?

Yes, they are very strong. Their high hardness handles tough minerals well. They resist chipping and breaking under pressure. This makes them reliable for continuous milling jobs.

How long do they last?

They last much longer than steel balls. Their wear resistance is excellent. You replace them less often. This saves money over time. They also resist chemical corrosion. Acids or alkalis don’t damage them easily.

Do they make milling more efficient?

Yes, they do. Their high density means they hit materials harder. This breaks particles down faster and finer. Less energy is needed to get the same result. You save power and get better grinding.

(High Precision 92% Al2O3 Alumina Ceramic Ball for Ball Mill)

REQUEST A QUOTE

RELATED PRODUCTS

High Alu Ceramic Ball Mill Bearing Balls 95% 92% 90% Al2O3 10mm 15mm 20mm Alumina Ceramic Balls Refractory Product

High Wear Resistance Al2O3 Ceramic Ball 92% Alumina High Quality High Density Low Wear Loss Ball

92% Alumina Grinding Balls: High-Purity, Wear-Resistant, Efficient for Industrial Milling and Dispersion Applications

Chemxin High Alumina Balls Support Media 6mm 10mm 19mm 38mm 99% Alumina Ceramic Ball

Whole Hydrogen Water Ceramic Ball Bio Ceramic Fire Balls Orp Inert Alumina Ceramic Ball