Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

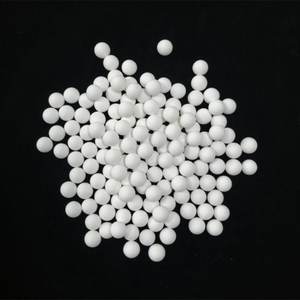

Overview of Industrial Wear-Resistant Alumina Ceramic Ball Media White Inert Ceramic Alumina Processing Services Welding Cutting Bending

Alumina balls are high-purity ceramic grinding media known for their exceptional hardness, wear resistance, and thermal stability. Ideal for industrial applications like milling, catalysis, and wear-resistant components.

Features of Industrial Wear-Resistant Alumina Ceramic Ball Media White Inert Ceramic Alumina Processing Services Welding Cutting Bending

High mechanical strength & durability

Excellent chemical & thermal stability

Superior wear & corrosion resistance

Available in various sizes & purity grades

Low contamination for precision processes

(Industrial Wear-Resistant Alumina Ceramic Ball Media White Inert Ceramic Alumina Processing Services Welding Cutting Bending)

Specification of Industrial Wear-Resistant Alumina Ceramic Ball Media White Inert Ceramic Alumina Processing Services Welding Cutting Bending

Industrial wear-resistant alumina ceramic sphere media offers trustworthy efficiency in hard processing work. This white inert ceramic product uses high-purity aluminum oxide. Its extreme solidity withstands consistent abrasion. The balls preserve their sizes and shape over long periods. This reduces failures and replacement costs significantly. Constant density makes sure predictable behavior in grinding and crushing machines. The spheres stand up to chemical assault from acids and antacids. This makes them safe for many damp and completely dry processes. They will not pollute delicate materials.

Offered dimensions range from tiny diameters to big ones. Typical sizes are 5mm, 10mm, 20mm, 30mm, 40mm, and 50mm. Custom sizes are possible. The smooth surface lessens friction and endure devices cellular linings. High alumina material guarantees reduced porosity. This stops absorption and boosts grinding efficiency. The balls are fired at really high temperatures. This sintering process develops a thick, resilient structure.

These alumina rounds work well in round mills, attritors, and vibratory mills. They are necessary in mining, ceramics, paint production, and chemical processing. Their inert nature is crucial for pharmaceutical and food-grade applications. They handle welding slag cleaning properly. The spheres aid in precise cutting and surface area ending up tasks. They are additionally used in material handling systems requiring wear resistance.

Processing solutions consist of customized shaping and sizing. Experts give welding assistance for ceramic components. Reducing and bending services adapt porcelains to specific machine designs. Technical advice aids pick the very best round size and alumina quality for your operation. Appropriate selection maximizes throughput and lessens media usage. This ceramic media delivers long life span under extreme conditions. It protects beneficial equipment from rapid wear.

(Industrial Wear-Resistant Alumina Ceramic Ball Media White Inert Ceramic Alumina Processing Services Welding Cutting Bending)

Applications of Industrial Wear-Resistant Alumina Ceramic Ball Media White Inert Ceramic Alumina Processing Services Welding Cutting Bending

Industrial wear-resistant alumina ceramic ball media supplies superior efficiency popular settings. These white ceramic rounds are very difficult. They withstand consistent rubbing and influence effectively. This makes them last a lot longer than steel spheres in lots of applications. The high alumina material ensures excellent chemical security. These balls won’t respond with most materials they call. They stay inert. This inertness is critical for purity-sensitive procedures.

You discover these white alumina rounds striving in grinding mills. They squash and mix products like minerals, paints, and ceramics. Their wear resistance maintains item contamination extremely low. Chemical plants rely on them as driver supports. Their inert surface area does not hinder reactions. Food and pharmaceutical processing uses them too. Their non-reactive nature secures item integrity.

The brilliant white shade provides a functional benefit. It makes aesthetic inspection for contamination or breakage much easier. Operators promptly find any type of problems. This aids maintain consistent item top quality.

We likewise offer expert alumina ceramic handling solutions. Need personalized forms or sizes? We exactly cut the ceramic to your specific demands. Specialized welding techniques join alumina components securely. We can additionally bend alumina ceramic components under regulated conditions. These solutions let you get perfectly customized ceramic solutions. Our team deals with the intricate manufacture work. You incorporate the high-performance ceramic parts directly right into your tools. This conserves you effort and time. Alumina ceramic bends, cuts, and welds require details experience. We have that knowledge.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Industrial Wear-Resistant Alumina Ceramic Ball Media White Inert Ceramic Alumina Processing Services Welding Cutting Bending

Industrial Wear-Resistant Alumina Ceramic Ball Media – White Inert Ceramic Alumina Processing Services (Welding, Cutting, Bending)

What are these alumina ceramic balls?

These are hard, white balls made mostly from aluminum oxide (alumina). They are designed for tough industrial jobs. They resist wear extremely well. They are used for grinding, milling, and processing materials.

Why use alumina ceramic balls instead of steel?

Alumina ceramic balls are much harder than steel. This means they last much longer. They wear down slower. This saves money over time. They also won’t rust. They won’t react with many chemicals. They are inert. This keeps processed materials pure.

What sizes and alumina levels are available?

We offer many sizes. Common sizes are from a few millimeters to over 50 millimeters. Alumina content is key. Higher alumina means better wear resistance and hardness. We provide balls with 92%, 95%, and 99%+ alumina. The right choice depends on your specific job and budget.

How are these ceramic balls made?

We start with fine alumina powder. We press it into ball shapes. Then we fire them at very high temperatures. This sintering process makes them incredibly hard and dense. Careful control ensures consistent quality and performance.

Do you offer services like cutting or welding these ceramics?

Yes. We supply the alumina balls. We also provide custom processing services. We can precisely cut ceramic parts. We can machine complex shapes. We offer specialized ceramic welding for repairs. We can bend ceramic components using unique methods. These services help fix parts or create custom solutions.

(Industrial Wear-Resistant Alumina Ceramic Ball Media White Inert Ceramic Alumina Processing Services Welding Cutting Bending)

REQUEST A QUOTE

RELATED PRODUCTS

99% Alumina Ceramic Ball Mill Pot/ Corundum Mill Jar

Cushion Filler Polishing Custom Bio Alumina Ceramic Balls Alkaline Mineral Purification Water Filter Media Shower Ball Decor

60-70% 65-75% 92% 95% High Alumina Balls Ceramic Grinding Ball for Ceramic Grinding Media

Wear Resistant Industry Zro2 Ceramic Ball Zirconia Alumina Ceramic Beads

Factory 92% High Alumina Ceramic Ball Alumina Balls For Grinding