Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

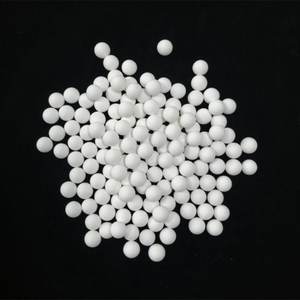

Overview of Used for Grinding Equipment Ceramic Beads Media High Hardness Alumina Grinding Ball

Alumina balls are high-purity ceramic grinding media known for their exceptional hardness, wear resistance, and thermal stability. Ideal for industrial applications like milling, catalysis, and wear-resistant components.

Features of Used for Grinding Equipment Ceramic Beads Media High Hardness Alumina Grinding Ball

High mechanical strength & durability

Excellent chemical & thermal stability

Superior wear & corrosion resistance

Available in various sizes & purity grades

Low contamination for precision processes

(Used for Grinding Equipment Ceramic Beads Media High Hardness Alumina Grinding Ball)

Specification of Used for Grinding Equipment Ceramic Beads Media High Hardness Alumina Grinding Ball

These ceramic grinding beads manage tough jobs. They are made mainly of alumina. Alumina makes them extremely hard. High hardness issues. Hard beads last much longer. They do not use down swiftly. You conserve money needing fewer substitutes. They stand up to damaging. Busted beads ruin your batch. These stay strong.

The beads can be found in many sizes. Common dimensions are 0.5 mm to 3mm. You select the size for your product. Smaller sized beads grind finer bits. Larger grains take care of bigger chunks. They operate in several equipments. Stirred mills, grain mills, attritors use them. They grind consistently.

Thickness is important. These grains have high density. High density suggests a lot more grinding power. They hit products harder. Grinding occurs much faster. You obtain finer outcomes quicker. They function well damp or dry. They don’t soak up liquid. Your slurry remains the ideal consistency.

They grind numerous materials. Minerals like quartz and zirconia need them. Ceramics, pigments, and electronic powders utilize them. Paints, inks, and coverings get smooth coatings. They manage chemicals. Acids and antacids do not damage them. They remain steady. Your item stays pure. No contamination takes place.

They are cost-effective gradually. Their firmness and density save energy. Devices run more effectively. You make use of less power. Downtime lowers. Maintenance costs drop. They are trustworthy grinding media. Several markets select them.

(Used for Grinding Equipment Ceramic Beads Media High Hardness Alumina Grinding Ball)

Applications of Used for Grinding Equipment Ceramic Beads Media High Hardness Alumina Grinding Ball

Ceramic grinding rounds made from high firmness alumina are crucial tools in numerous sectors. They grind materials down to really great fragments. These grains work inside mills and grinding equipments. Their extreme hardness makes them crush hard materials properly. Alumina beads last a lot longer than steel rounds. This conserves money because substitutes happen less typically. Wear is very little during procedure. Contamination threats go down dramatically too.

Mining and minerals handling rely heavily on alumina grinding media. They grate ores like quartz, feldspar, and kaolin. Getting consistent, fine powders is important below. The grains take care of the unpleasant nature of these products well. Their hardness avoids them breaking down as well fast.

Paints, inks, and finishes suppliers utilize these beads. Achieving smooth, even color dispersion requires extreme grinding. Alumina beads supply the required pressure without including steel contaminations. The final product top quality improves significantly. Color stamina and security advantage.

Electronics making demands ultra-pure materials. Alumina grinding grains are chemically inert. They grind ceramic powders and electronic pastes without contamination. Bit dimension control is specific. This purity is important for elements like capacitors and resistors.

Chemical handling plants make use of alumina grains. They grind drivers and various other responsive powders. The grains stand up to chemical assault. They maintain integrity also in rough environments. Consistent grinding results are ensured.

Pharmaceuticals require rigorous hygiene and pureness. Alumina grinding media satisfies these requirements. They mill energetic components and excipients properly. Contamination from the grinding media itself is virtually absolutely no. Item security is guaranteed.

These grains are additionally exceptional for grinding food. They deal with flavors and food colorings securely. Their inert nature stops modifying preference or introducing hazardous elements.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Used for Grinding Equipment Ceramic Beads Media High Hardness Alumina Grinding Ball

What are alumina grinding balls?

These are small ceramic beads made from aluminum oxide. People use them in grinding equipment. They crush materials into fine powders. Many industries need them.

Why is high hardness important?

Hard beads wear down slowly. This saves money over time. They break less often too. Hard beads keep the ground material pure. Softer beads can leave bits behind. This contaminates the product.

What sizes are available?

Many sizes exist. Common sizes range from 1mm to 50mm. The right size depends on your machine. It also depends on how fine you need the powder. Smaller beads make finer powder. Larger beads handle bigger chunks first.

How long do they last?

They last much longer than steel or glass beads. Their lifespan depends on the material you grind. It also depends on machine speed and operating time. Expect many cycles before replacement. Check them regularly for wear.

Where are they typically used?

They work in ball mills and stirred mills. Common uses include grinding minerals for mining. They grind ceramic powders for tiles. They grind chemicals. They grind paints and pigments. They are also used in electronics materials.

(Used for Grinding Equipment Ceramic Beads Media High Hardness Alumina Grinding Ball)

REQUEST A QUOTE

RELATED PRODUCTS

Factory High Purity 99.99 Alumina Grinding Media Balls Beads for Industrial Mills

Factory High Hardness Alumina Purity 68% 92% 95% Ceramic Alumina Grinding Ball for Wet Dry Grinding Machine

Factory Whole 30-60mm White 99% Al203 High Alumina Machine Pressure Grinding Ball Ceramic Ball

Factory Zibo Grinding Media 92% Aluminum Oxide Al2O3 Alumina Ceramic Balls for Ball Mill

Porcelain Balls 3mm 6mm 10mm 17% Inert Alumina Support Media Ceramic Balls For Distilling