Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

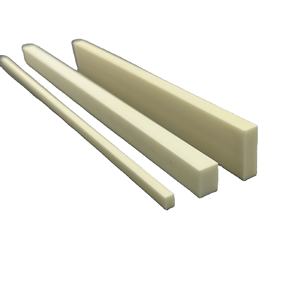

Overview of 96% Al2O3 Ceramic Round Bar and Alumina Shaft

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of 96% Al2O3 Ceramic Round Bar and Alumina Shaft

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of 96% Al2O3 Ceramic Round Bar and Alumina Shaft

Below’s the spec for 96% Al2O3 ceramic round bars and alumina shafts. This material is alumina ceramic. It contains 96% light weight aluminum oxide. This makes it extremely hard. It stands up to wear very well. These ceramics supply high mechanical strength. They manage compression lots properly. They are breakable though. Avoid effect stress. They maintain their form at heats. They deal with continual heat up to 1600 ° C. They stand up to thermal shock halfway decent.

The surface area is really smooth. It really feels brightened. This decreases rubbing. It minimizes wear against other components. These ceramics withstand chemical strike. Acids and antacids do not harm them easily. They are chemically inert. They are additionally an excellent electrical insulator. This works in electric applications. Moisture absorption is near no. This avoids swelling or compromising.

96% alumina bars are dense. Thickness has to do with 3.7 g/cm TWO. They are tight. The material doesn’t flex much. The color is usually white. It can be beige. The finish is fine-grained. It corresponds.

These round bars and shafts function well popular jobs. Use them as pump shafts. They take care of rough fluids. They are good as wear-resistant guides. They function as precise rollers. They are dependable insulators in electronic devices. They are strong assistance pins. They are secure heater parts. They are long lasting in chemical environments. Machining this ceramic is hard. Grinding and splashing are needed for tight tolerances. Accuracy grinding achieves precise diameters. It achieves great surface area finishes.

These components require careful handling. Stay clear of dropping them. Prevent striking them. Secure the ends throughout installation. Proper mounting avoids splitting.

Applications of 96% Al2O3 Ceramic Round Bar and Alumina Shaft

Alumina ceramic round bars and shafts made from 96% Al2O3 offer serious advantages in difficult areas. This material is extremely hard. It stands up to using down exceptionally well. It deals with high warm as well. It remains strong in hot locations. It likewise obstructs electricity. This makes it safe for electrical tasks.

These rounded bars see heavy use. They come to be linings inside pipes and chutes lugging rough stuff. Sand, powders, ores wear steel quickly. Alumina ceramic lasts a lot longer. This saves money on replacements. Manufacturing facilities utilize them as overviews for wire and cable television. The smooth surface minimizes rubbing. The solidity prevents grooves. They are crucial parts in cutting systems. They hold blades firmly. They stand up to the forces included. They serve as solid, wear-proof rollers in conveyors.

Alumina shafts are accuracy parts. Equipments need smooth, straight rods. Alumina shafts provide this. They operate in pumps and shutoffs moving harsh fluids. Acids, solvents, and seawater damage steel. Alumina ceramic neglects them. This stops corrosion failing. These shafts master high-speed bearings. They create less warm. They require much less lubrication than steel. Their rigidity indicates they do not flex under tons. This maintains machines running precisely. They are excellent for electric tools. Their insulation prevents sparks or shorts. Motors and sensors use them securely.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 96% Al2O3 Ceramic Round Bar and Alumina Shaft

What temperature can alumina ceramic bars handle?

Alumina ceramic bars handle extreme heat. They work fine up to 1700°C. They won’t melt or weaken significantly below this point. This makes them ideal for hot environments.

Are these ceramic bars good for wear?

Yes, they are excellent for wear resistance. Alumina ceramic is very hard. It lasts much longer than steel in abrasive conditions. Parts experience less wear over time.

Can chemicals damage alumina shafts?

Most chemicals won’t damage alumina shafts. They resist acids and alkalis well. Only strong hydrofluoric acid or hot caustics cause problems. They are safe for many chemical processes.

Is ceramic stronger than steel?

Alumina ceramic is harder than steel. It resists scratching better. But it is more brittle. Steel bends before breaking. Ceramic breaks suddenly under heavy impact. Choose based on the stress type.

How careful must I be installing them?

Handle alumina shafts carefully. Avoid impacts or dropping them. Use proper support during installation. Don’t overtighten fittings. Sudden force can crack them. Treat them like glass.

REQUEST A QUOTE

RELATED PRODUCTS

1050 6061 Aluminum Hexagonal bar / 7075 Aluminum Hexagonal Rod

99%/95%Al2o3 Alumina Ceramic Stick Refractory Material Ceramic Cuboid bar

Custom Color Barbell Bar Competition Weightlifting Barbells Ceramic Coated Straight Powerlifting Barbell

Aviation Duralumin Alloy Rod 7075 T6511 Aluminum Round Bar

Industrial Aluminum Rod 1050 2024 T4 7075 T6 110mm 120mm 130mm Round Bar 1070 6061 2024 Alloy Material Cutting Service Available