Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

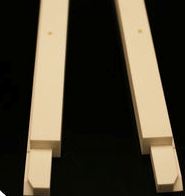

Overview of 99 Alumina High Temperature Resistant Ceramic Arc Ceramic bar

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of 99 Alumina High Temperature Resistant Ceramic Arc Ceramic bar

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of 99 Alumina High Temperature Resistant Ceramic Arc Ceramic bar

This alumina ceramic bar deals with severe heat well. It has 99% pure aluminum oxide. This product choice gives it excellent thermal stability. It stands up to temperature levels as much as 1700 degrees Celsius. This makes it trusted for harsh heater settings. You will not see warping or splitting under regular high-heat usage. It maintains its sizes and shape.

Bench supplies solid electrical insulation. Its quantity resistivity stays high even at heats. This avoids current leak. It functions securely in electric heating elements. It offers great assistance without conducting power. Arc resistance is an additional vital attribute. It withstands damages from electric arcing. This is important for components near high voltages.

Mechanical toughness goes over for a ceramic. It has high solidity. This shields it versus wear and abrasion. It resists surface area scrapes. The material additionally has great compressive toughness. It supports heavy lots without breaking. This toughness extends its life span.

Surface area finish is typically really smooth. This reduces friction where parts slide or step. Dimensional precision is typical. Resistances are snugly controlled during production. This guarantees parts fit appropriately in assemblies. Colors are normally white or ivory. This suggests high purity.

Usual usages include heating system cellular linings, kiln furnishings, and thermocouple defense tubes. It works well in sintering trays and warm therapy sustains. Electrical applications consist of insulators and arc chutes. Its high-temperature security and electric buildings make it versatile. It performs accurately where steels or plastics stop working.

Applications of 99 Alumina High Temperature Resistant Ceramic Arc Ceramic bar

These 99% alumina ceramic arc bars handle severe warmth exceptionally well. They withstand temperature levels up to 1800 ° C without softening or damaging down. This makes them ideal for demanding high-heat work. They give wonderful electrical insulation even at those intense temperatures. You will not obtain electric shorts or leakage.

Their stamina goes over. They withstand physical damage extremely. They do not conveniently fracture or chip under mechanical anxiety. This strength is important in harsh commercial settings. They keep functioning accurately in time.

You see these bars inside electrical heaters and kilns. They support burner securely. They handle the high currents without deteriorating. Welding tools uses them as well. They position electrodes correctly and deal with the welding arc’s warmth.

Semiconductor manufacturing relies on them. They hold wafers during high-temperature procedures. Their pureness ensures no contamination. They are steady in destructive chemical atmospheres. Labs and chemical plants utilize them therefore.

High-voltage equipment requires their insulation. They isolate parts in power transmission systems. They protect against harmful arcing. Their thermal security keeps whatever safe. Aerospace applications take advantage of their lightweight strength. They endure the heat and anxiety inside engines and other systems.

These bars are vital for scenarios requiring serious warmth resistance and electric seclusion. Their toughness and security resolve troubles in numerous challenging markets. They execute continually where various other products stop working.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 99 Alumina High Temperature Resistant Ceramic Arc Ceramic bar

What’s the maximum temperature this ceramic bar handles?

It withstands temperatures up to 1800°C. This makes it ideal for very hot environments. It won’t melt or deform easily under intense heat.

Where is this high-temperature ceramic bar typically used?

You find it in industrial furnaces and kilns. It’s common in heating elements and thermal processing equipment. It works well where extreme heat is constant.

Why choose ceramic over metal for high heat?

Ceramic resists oxidation much better than metal. Metal parts can corrode and fail quickly in high heat. This ceramic lasts longer, saving replacement costs.

Is this ceramic bar a good electrical insulator?

Yes, it provides excellent electrical insulation. This is crucial near heating elements. It prevents dangerous electrical shorts.

How fragile is the 99% alumina ceramic?

Handle it carefully. It is hard but can crack under sharp impact. Avoid dropping it. Use proper tools during installation.

REQUEST A QUOTE

RELATED PRODUCTS

Custom alumina high temperature ceramic bar/strips/blocks

High Quality Premium Alumina Ceramic Parts Industrial Wear-Resistant Custom Accessories-Alumina Rod Cutting Welding

Factory s Customized 1050 1100 3003 5083 6061 6063 7075 Aluminum Alloy Bar Rod

Aviation Duralumin Alloy Rod 7075 T6511 Aluminum Round Bar

Custom Size High Quality Wear and Corrosion Resistant Alumina Ceramic Rod Needle Bar