Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

Overview of Aluminum Flat Bar 4032 5083 7175 7075 6061 Aluminum Hex Bar Aluminum Bars 6063

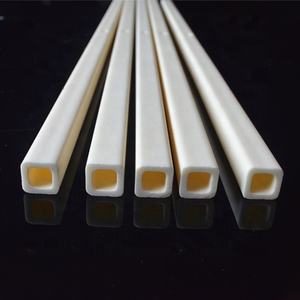

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of Aluminum Flat Bar 4032 5083 7175 7075 6061 Aluminum Hex Bar Aluminum Bars 6063

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of Aluminum Flat Bar 4032 5083 7175 7075 6061 Aluminum Hex Bar Aluminum Bars 6063

Right here’s info about light weight aluminum flat bars, hex bars, and specific alloys. We provide aluminum flat bars in several vital alloys. Alloy 6061 is commonly utilized. It uses excellent toughness and workability. It machines well. It welds well. It withstands deterioration successfully. 6061 is common in construction, structures, equipment parts, and consumer goods. Alloy 5083 offers superb corrosion resistance, particularly in aquatic setups. It takes care of deep sea direct exposure accurately. Its toughness remains great after welding. 5083 is a top choice for watercraft hulls, aquatic elements, and chemical tanks. Alloys 7075 and 7175 are high-strength choices. They are among the best light weight aluminum alloys offered. 7075 is frequently made use of in aerospace structures, high-performance bike components, and requiring applications. 7175 deals also greater toughness than 7075. It matches critical aerospace parts completely. Alloy 4032 is understood for low thermal growth and great wear resistance. It does well in high-heat situations like pistons and engine parts.

We additionally supply aluminum hex bars. Alloy 6063 is the common option for hex bars. It excels in extrusion processes. It uses great surface area finish capacity. It makers easily. It anodizes perfectly. 6063 hex bars are ideal for architectural trim, home window frames, door frameworks, furniture components, and ornamental applications. These aluminum bars come in common dimensions. Customized sizes are often feasible. Level bars offer a straightforward rectangular cross-section. Hex bars provide a six-sided form for grasping devices or fittings. Picking the best alloy depends on your task requires. Think about needed stamina, rust resistance, machinability, weldability, and last application. We supply these products to meet diverse industrial and fabrication needs.

Applications of Aluminum Flat Bar 4032 5083 7175 7075 6061 Aluminum Hex Bar Aluminum Bars 6063

Light weight aluminum bars can be found in different shapes and alloys. Each kind fits particular jobs well. Flat bars and hex bars are common shapes. The alloy number tells you regarding the steel’s properties. Aluminum 4032 handles heat extremely well. It is frequently made use of inside engines. You discover it in pistons and cyndrical tube components. It stands up to wear in time. Aluminum 5083 is terrific for deep sea. Boats and marine devices use it a lot. It stands up to corrosion highly. This alloy is additionally difficult for welding tasks.

Light weight aluminum 7175 and 7075 are very strong. They are several of the hardest light weight aluminum alloys readily available. Aerospace parts require this toughness. Airplane frameworks and installations utilize 7175 and 7075. High-stress elements count on them. They are difficult to weld however. Light weight aluminum 6061 is popular. It supplies a good mix of stamina and workability. Building contractors utilize it for frames and frameworks. Machinists like it for components. It welds halfway decent and withstands rust. It’s a reputable general-purpose alloy.

Light weight aluminum 6063 is understood for smooth finishes. It extrudes easily into forms. Engineers select it for home window frameworks and trim. It polishes well and anodizes magnificently. It’s not as strong as 6061 for hefty lots. Hex bars have six sides. This form offers a great hold. Hex bars made from 6061 or 6063 prevail. They are developed into bolts, installations, and shafts. The hex shape quits devices from slipping. You locate them in equipment and bolts.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Aluminum Flat Bar 4032 5083 7175 7075 6061 Aluminum Hex Bar Aluminum Bars 6063

What aluminum alloys do you offer for flat and hex bars?

We stock flat bars and hex bars in alloys 4032, 5083, 7175, 7075, 6061, and 6063. These cover a wide range of uses. Each alloy has different strengths and weaknesses.

Why choose 6061 aluminum bars?

6061 is very popular. It offers good strength. It machines well. It welds well. It resists corrosion decently. It’s a great all-rounder for many projects. Think frames, fittings, and general parts.

When should I use 7075 or 7175 aluminum?

Pick 7075 or 7175 when you need maximum strength. These are among the strongest aluminum alloys available. They work well for high-stress parts like aerospace components or high-performance equipment. Remember, they are harder to machine and weld than 6061. They cost more too.

Is 5083 aluminum good for marine use?

Yes, 5083 is excellent for saltwater and marine settings. It resists corrosion from seawater exceptionally well. This makes it perfect for boat hulls, docks, and other marine structures. Its strength holds up in these harsh environments.

What about 4032 and 6063 aluminum bars?

4032 excels in high-temperature situations. It keeps its strength when things get hot. It’s often used in pistons and engine parts. 6063 is known for its great finish and easy forming. It’s the top choice for architectural extrusions like window frames and trim. It looks good and shapes easily.

REQUEST A QUOTE

RELATED PRODUCTS

Machinable Ceramic Bar / Standard Sizes Stock Available 5*30

Spot Supplies Aluminum Billet and Ingot 6061 6063 Aluminium bar Alloy Rod Aluminum Round bar

Custom 95% Al2O3 Ceramic Rod Wear Corrosion Resistant Alumina Bar

3003 Extruded Aluminium Bar Good Molding Performance High Corrosion Resistance Custom Aluminum Square Bar Aluminium Welding Rod

Precision Customized Drilling Grinding Alumina Ceramic Porous Stick bar Rod