Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

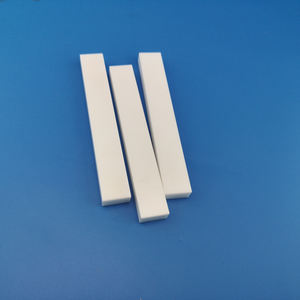

Overview of Ceramic Eyelets 99% Alumina Ceramic Wire Guide ,yarn Guide Parts Ceramic bar

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of Ceramic Eyelets 99% Alumina Ceramic Wire Guide ,yarn Guide Parts Ceramic bar

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of Ceramic Eyelets 99% Alumina Ceramic Wire Guide ,yarn Guide Parts Ceramic bar

Our ceramic eyelets are crafted from 99% alumina ceramic. This material ensures exceptional durability and performance. These eyelets serve as reliable wire guides and yarn guides. They are commonly mounted on ceramic bars for industrial use. The high alumina content makes them extremely hard. This hardness resists wear from constant friction. Wires or yarns slide smoothly through them. Surface abrasion on materials is minimized.

These guides handle high temperatures well. Thermal stability prevents cracking or warping. They work in hot environments without failing. Electrical insulation properties are excellent. This prevents short circuits in electronic applications. Chemical resistance is another key feature. Acids and alkalis do not damage the ceramic.

Precision manufacturing guarantees uniform hole sizes. Consistent sizing avoids snags or breaks in threads. Each eyelet has a polished interior surface. Smooth passage of materials is assured. Installation is simple on existing machinery. The ceramic bars hold multiple eyelets securely.

Long service life reduces maintenance costs. Replacement frequency drops significantly. Textile factories benefit from reduced downtime. Wire production lines see fewer interruptions. These parts are ideal for demanding settings. Manufacturing plants rely on their toughness.

Operational efficiency improves with these guides. Material waste from breaks decreases. Production quality remains consistently high.

Applications of Ceramic Eyelets 99% Alumina Ceramic Wire Guide ,yarn Guide Parts Ceramic bar

Ceramic eyelets, wire guides, and bars made from 99% alumina ceramic solve tough problems in factories. These parts handle wires, yarns, and threads moving very fast. Regular metal or plastic parts wear out quickly. They cause friction. Friction breaks delicate materials. It also creates messy dust. Alumina ceramic parts are much harder. They last much longer. You need replacements less often. This saves money and stops production delays.

The super smooth surface of 99% alumina ceramic is key. It lets materials slide easily. There is almost no drag. This protects fragile wires and fine yarns. Snags and breaks happen less. Product quality improves. Less waste means lower costs. The ceramic won’t wear down from constant rubbing. It stays smooth for a long time. It also resists heat extremely well. Hot environments won’t damage these guides. They keep working reliably.

These ceramic components are very stable. They don’t change shape with temperature shifts. This keeps tension on wires or yarns consistent. Consistent tension is vital for good results. The material is chemically inert too. Harsh chemicals or oils won’t affect it. Cleaning is simple. It just wipes clean. Maintenance is minimal.

You find these alumina ceramic guides everywhere. They guide copper wire in cable making machines. They control synthetic yarns in textile factories. They handle fine glass fibers for electronics. They position welding wire accurately. They manage threads in high-speed sewing. They even work in tough places like wire drawing or fiber optic production. They handle the speed. They handle the abrasion. They keep things running smoothly.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Ceramic Eyelets 99% Alumina Ceramic Wire Guide ,yarn Guide Parts Ceramic bar

Ceramic Eyelets FAQs: 99% Alumina Wire & Yarn Guides

People often ask questions about our 99% alumina ceramic eyelets, wire guides, and yarn guide bars. Here are the top five:

Why use alumina ceramic for these parts?

Alumina ceramic is extremely hard. It resists wear much better than metal or plastic. This hardness means guides last longer. They handle constant friction from wires or yarns well. They won’t deform easily.

What’s the maximum temperature these guides withstand?

These alumina ceramic parts handle very high heat. They work fine up to 1600°C (2912°F). This makes them perfect for hot processes. Metal guides might warp or fail at these temperatures. Alumina stays stable.

Why is the surface so smooth?

We polish the alumina ceramic to a fine finish. A smooth surface is critical. It minimizes friction on the wire or yarn. Reduced friction prevents snagging and breakage. It ensures smooth, consistent feeding through machines.

How do I clean ceramic guides?

Cleaning is simple. Use a soft brush to remove loose dust or lint. For tougher residues, use mild soap and water. Avoid harsh chemicals or abrasive cleaners. They might scratch the ceramic surface. Rinse thoroughly and dry.

Can I get custom sizes or shapes?

Yes, we offer customization. Standard sizes are available. We make specific sizes or shapes to fit your machinery. Tell us your requirements. We produce guides tailored to your exact application needs.

This alumina ceramic resists chemical corrosion too. It works reliably in tough industrial environments. The material doesn’t conduct electricity. It provides excellent electrical insulation where needed. These parts are essential for consistent production quality. They reduce downtime and maintenance costs significantly.

REQUEST A QUOTE

RELATED PRODUCTS

China Factory 10mm 20mm 30mm 1370 Aluminium Bar Aluminum Rod For

Extruded Aluminium Flat bar 6061 T6 Alloy

Cutting Size Aluminum Alloy Bar Rod 6061 6063 6082 Hot s Ship Materials Whole

1050 6061 Aluminum Hexagonal bar / 7075 Aluminum Hexagonal Rod

High Quality Machinable Zirconia Toughened Alumina Ceramic ZTA Bars for Industrial Mould Cut to Size with Wear Resistance