Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

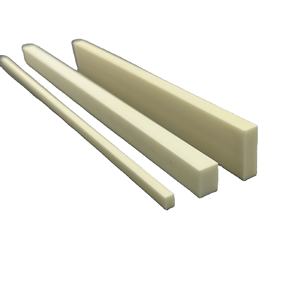

Overview of Customized Industrial High Polish Wear Resisting 99 Al2o3 Alumina Ceramic Rod bar

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of Customized Industrial High Polish Wear Resisting 99 Al2o3 Alumina Ceramic Rod bar

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of Customized Industrial High Polish Wear Resisting 99 Al2o3 Alumina Ceramic Rod bar

Our customized industrial alumina ceramic rods provide phenomenal performance in challenging settings. These poles are made from 99% pure aluminum oxide (Al2O3). This high purity provides exceptional firmness. They stand up to use extremely well. This indicates they last much longer than several steels or plastics. Friction creates less damages to them. They deal with harsh conditions easily.

We provide specific modification for your specific demands. You can pick the specific size you require. You can define the perfect length for your application. We make poles in numerous cross-sectional shapes too. Round rods are conventional. We likewise create square, hexagonal, or other profiles. Inform us your dimensions. We make poles to match your technical drawings.

An essential attribute is the high-polish surface coating we give. This smooth surface decreases rubbing significantly. It reduces product sticking or accumulation. It also makes cleaning simpler. This coating is important for parts needing low rubbing. It assists in applications including gliding or turning get in touch with.

These poles withstand really heats. They perform accurately under intense warm. They are outstanding electrical insulators. They do not carry out electrical power. They resist strike from numerous solid chemicals. Acids and antacid cause them little injury. They are additionally biocompatible. This makes them ideal for certain medical uses.

These properties make our alumina ceramic poles suitable for demanding industrial jobs. They function well in pump seals and shutoff components. They are best for precision shafts and bearing sleeves. Utilize them in wear overviews and linings. They operate in high-temperature sensor real estates. They serve in chemical processing equipment. They are found in semiconductor handling tools. They operate in textile equipment parts. They are crucial for any type of place requiring hard, wear-proof, smooth elements.

We focus on quality and conference your exact specifications. Our poles give a reputable, long-lasting option. They manage challenging atmospheres properly.

Applications of Customized Industrial High Polish Wear Resisting 99 Al2o3 Alumina Ceramic Rod bar

These custom high-polish wear-resistant alumina ceramic rods solve hard commercial challenges. Their severe solidity and smooth surface area coating make them excellent for requiring applications. Aluminum oxide (Al2O3) uses superior resistance to abrasion and corrosion. This indicates components last much longer than steel choices. Lowered downtime conserves considerable cash.

In semiconductor production, these sleek rods are necessary. They guide wafers exactly without contamination. Their level of smoothness stops bit generation. Their chemical resistance manages rough cleaning processes. This dependability is essential for cleanroom environments.

Fabric machinery relies on them for smooth string and yarn motion. The polished surface area minimizes friction. This protects against fiber damage and breakage. It guarantees regular, top notch material production. Operators see less interruptions.

Printing and packaging tools advantages significantly. These rods guide products accurately. Their wear resistance preserves precision in time. Print quality keeps constant. Manufacturing speeds remain high. Maintenance needs drop greatly.

Food processing uses them for hygienic reasons. The non-porous refined surface resists germs accumulation. It stands up to regular cleansing with strong chemicals. These rods fulfill rigorous health requirements. They ensure product safety and security.

Automation systems make use of these rods as strong overviews and supports. Their dimensional stability is excellent. They give trusted direct movement. Devices runs smoothly for longer periods. They are a cost-effective solution.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Customized Industrial High Polish Wear Resisting 99 Al2o3 Alumina Ceramic Rod bar

Here are 5 common questions about our Customized Industrial High Polish Wear Resisting 99 Al2O3 Alumina Ceramic Rods:

What makes alumina ceramic rods special? Alumina ceramic rods are super hard. They resist scratches very well. They handle high heat too. This makes them tough for demanding jobs. Metals often wear out faster. Alumina lasts longer.

How much heat can these rods take? These rods work fine up to 1600°C. They don’t melt or weaken easily. This is important for hot environments. They keep their shape under heat stress. This beats many metals.

Can you make custom sizes? Yes. We make rods exactly how you need them. Tell us the diameter. Tell us the length. We cut it precisely. This ensures a perfect fit for your machine or tool. Standard sizes are available too.

What does “High Polish” mean? High polish means a super smooth surface. We grind the rod finely. This reduces friction a lot. Less friction means less wear. It also stops things from sticking. You can choose different polish levels. Mirror finish is the smoothest.

Are they really wear-proof? Nothing lasts forever. But alumina ceramic rods resist wear extremely well. They are much harder than steel. Abrasive materials don’t damage them easily. They handle constant rubbing and scraping. This leads to less downtime. You save money on replacements.

REQUEST A QUOTE

RELATED PRODUCTS

1050 6061 Aluminum Hexagonal bar / 7075 Aluminum Hexagonal Rod

99% Al2o3 Alumina Ceramic Rod Bar Surface Polished Insulation Stick Used in Textile Industry

Aviation Duralumin Alloy Rod 7075 T6511 Aluminum Round Bar

Factory s Customized 1050 Aluminum Alloy Bar Rod

96% Al2O3 Ceramic Round Bar and Alumina Shaft