Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

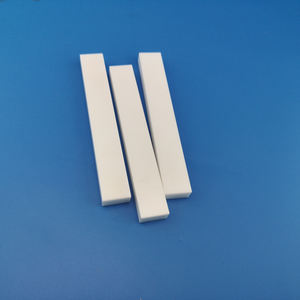

Overview of Customized Zirconia Ceramic Strip Bar for Industrial Ceramic Applications with Services of Cutting Bending & Welding

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of Customized Zirconia Ceramic Strip Bar for Industrial Ceramic Applications with Services of Cutting Bending & Welding

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of Customized Zirconia Ceramic Strip Bar for Industrial Ceramic Applications with Services of Cutting Bending & Welding

Personalized Zirconia Ceramic Strip Night clubs fix challenging problems popular markets. We make these bars exactly just how you need them. Zirconia ceramic is exceptionally difficult. It resists wear incredibly well. This material pokes fun at high temperatures. It won’t split under unexpected heat adjustments. Chemicals hardly touch it. These buildings are crucial for harsh atmospheres.

You tell us the size. We provide accurate dimensions. Length, width, density– we struck your targets. Limited tolerances are conventional. We recognize precise fits issue in equipment. Consistency is ensured set after set. You obtain trustworthy components every time.

Our solution exceeds just supplying the ceramic strip. We manage the shaping also. Required pieces cut to particular lengths? We do that accurately. Need complex bends or contours? Our techniques create the ceramic without breaking it. Need components signed up with? We provide specialized welding for zirconia. This saves you time and inconvenience. You obtain parts all set for installment.

These custom-made zirconia strips are made use of extensively. They are ideal for heating system cellular linings and kiln furniture. They excel as wear plates in heavy equipment. They secure surfaces in chemical processing equipment. They are important in aerospace parts. They function well in clinical gadget production. They are type in semiconductor production tools. They provide long life where steels fail.

We concentrate on your specific difficulty. Tell us your application demands. We provide the ideal zirconia remedy. Our cutting, bending, and welding services deliver ended up parts. Get the efficiency of advanced ceramics formed for your work.

Applications of Customized Zirconia Ceramic Strip Bar for Industrial Ceramic Applications with Services of Cutting Bending & Welding

Custom-made zirconia ceramic strip bars solve tough issues in numerous sectors. These ceramic parts are extremely strong. They stand up to put on incredibly well. They manage really heats without damage. Zirconia stays stable in harsh chemicals as well. This makes them ideal for requiring places.

Manufacturing facilities utilize these strip bars in several means. They line high-wear areas inside machines. This safeguards metal parts from abrasion damage. Heater home builders use them as heat shields. Electronics makers require them as exact protecting bases. Chemical plants rely on their resistance to corrosion. The material functions where steels fail.

Getting the exact form matters. Off-the-shelf components hardly ever fit completely. That’s why custom-made sizes are essential. Specify the length you need. Offer the required size. Tell us the essential density. We make it precisely for your machine or procedure.

We likewise offer crucial shaping solutions. Need the strip bar cut to a complex summary? Our accurate cutting takes care of that. Require a particular bend or contour? Our specialized bending techniques form the ceramic accurately. Occasionally assembly requires welding. We offer professional ceramic welding to join pieces firmly. This saves you time and inconvenience.

These services mean you obtain a ready-to-install part. You avoid dangerous in-house ceramic job. The outcome is an ideal suitable for your application. This brings about longer devices life. It minimizes expensive downtime for repair services. It improves overall process dependability.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Customized Zirconia Ceramic Strip Bar for Industrial Ceramic Applications with Services of Cutting Bending & Welding

Customized Zirconia Ceramic Strip Bar: 5 Key Questions Answered

What sizes can you make these zirconia strip bars?

We make zirconia strip bars in many sizes. Tell us what you need. We cut the material to your exact length. We also cut it to your exact width. We cut it to your exact thickness. We focus on your specific industrial application.

Why pick zirconia ceramic for strip bars?

Zirconia is very strong. It resists wear extremely well. It handles high temperatures easily. It stays cool longer than other ceramics. It won’t crack easily under stress. These features make it perfect for tough industrial jobs.

Can you machine the strips for me?

Yes, we offer full machining services. We precisely cut the strips to your drawings. We expertly bend zirconia into complex shapes when needed. We also weld zirconia parts together securely. We handle the fabrication so you get ready-to-use components.

How smooth is the zirconia surface?

We achieve a very smooth finish. This smoothness reduces friction. Reduced friction means less wear on moving parts. Less wear means longer component life. This is critical for applications like precision guides or seals.

How tough are these zirconia strips?

Zirconia strip bars are incredibly tough. They resist breaking far better than many other ceramics. This toughness comes from the material’s special structure. It handles impacts and heavy loads reliably. You get long-lasting performance in demanding environments.

REQUEST A QUOTE

RELATED PRODUCTS

Industrial heating alumina ceramic rods/Al2O3 bar

End Cut High Wear Resistance High Polished 99% Alumina Bar

Isostatic Pressing 95 Alumina Ceramic Round bar Ceramic Rod Heating element Knife Grinder

DC12V RGB LED Strip Light 5050 RGB Tube Light LED PCBA Design RGB LED Light Bar

Advanced Low Density High Dielectric Strength Macor Machinable Glass Ceramic Bar