Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

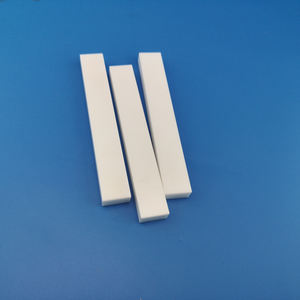

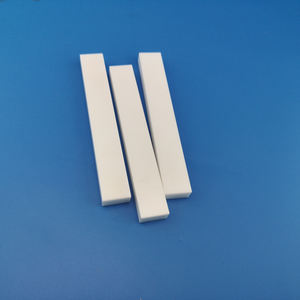

Overview of Diamond Polishing 99% AL2O3 Bar Alumina Ceramic Rod

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of Diamond Polishing 99% AL2O3 Bar Alumina Ceramic Rod

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of Diamond Polishing 99% AL2O3 Bar Alumina Ceramic Rod

This alumina ceramic pole contains 99% light weight aluminum oxide (AL2O3). It is developed especially for demanding diamond polishing tasks. The material is unbelievably tough. This firmness guarantees efficient product elimination during polishing. It also stands up to wear remarkably well. The pole preserves its form and surface stability over long periods. This toughness translates straight right into price financial savings. You replace devices much less commonly.

The rod manages sudden temperature modifications effectively. Thermal shock resistance is a key feature. Sprucing up creates substantial warmth. This pole will not fracture or deteriorate under that heat stress and anxiety. It carries out accurately in high-heat settings. Stability is essential for regular gloss high quality.

Its surface coating is remarkably smooth. This smoothness stops scratching fragile diamond surface areas. It supplies the necessary great abrasion required for a perfect polish. Accuracy is non-negotiable in diamond job. This rod supplies that precision constantly.

Criterion diameters vary from 3mm to 20mm. Lengths are typically 100mm to 500mm. Customized dimensions are often readily available. You can find the right size for your certain brightening machine and ruby kind. The rod is chemically inert. It does not react with usual sprucing up substances or coolants. This ensures the polishing procedure remains pure and uncontaminated. Chemical stability secures both the diamond and the device. The rod is easy to deal with and install into brightening tools. Its strength supplies excellent control throughout operation. Regular stress application is straightforward. Operators attain consistent outcomes effectively. The alumina ceramic product supplies excellent electrical insulation residential properties. This is very important near brightening equipment. It adds a safety layer.

Applications of Diamond Polishing 99% AL2O3 Bar Alumina Ceramic Rod

This alumina ceramic pole contains 99% aluminum oxide. That’s AL2O3. It is very tough. It is also really dense. This product withstands wear incredibly well. It takes care of heat well. It stays strong also at heats. These attributes make it ideal for diamond tool production.

Diamond devices need strong assistance. The ruby grit is extremely hard. The base product have to be equally challenging. This pole provides that solid base. It holds the rubies securely during cutting and grinding. This protects against the rubies from removing. It makes the tool last much longer.

Manufacturers utilize this pole commonly. It forms ruby grinding wheels. It develops diamond polishing pads. It constructs diamond cutting sectors. It creates ruby clothing devices. These tools reduced concrete, rock, glass, and ceramics. They grind tough metals. They polish surface areas to a fine coating.

The pole’s hardness matches the diamond grit. This implies even put on. The tool stays sharp longer. Its warm resistance is essential. Sprucing up creates high heat. This pole won’t warp or crack under that warmth. Its stability makes sure constant efficiency. Devices function reliably in time.

Its wear resistance is superior to steel. It lasts much longer. This reduces downtime. It reduces replacement expenses. Manufacturing performance boosts. The smooth surface finish of the rod is necessary. It allows precise positioning of diamond fragments. This develops an even, reliable reducing surface area. The pole is chemically steady. It won’t respond with coolants or various other products made use of in polishing. This avoids contamination. Device efficiency stays high.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Diamond Polishing 99% AL2O3 Bar Alumina Ceramic Rod

What is the Diamond Polishing 99% AL2O3 Bar Alumina Ceramic Rod used for? This rod polishes diamond tools and surfaces. It makes diamonds smooth and shiny. Jewelers and industrial workers rely on it for finishing tasks. What makes this ceramic rod better than other tools? It contains 99% alumina. This makes it very hard and durable. It doesn’t wear down quickly. Other tools break faster or lose effectiveness. This rod stays reliable longer. How do I use the ceramic rod for polishing? Hold the rod firmly. Rub it against the diamond surface with steady pressure. Move it back and forth evenly. Keep polishing until the diamond looks smooth. It’s simple and doesn’t need special skills. How long does the ceramic rod last? It lasts a long time. The high alumina material resists wear. You can polish many diamonds with one rod. It stays effective even with heavy use. This saves money over time. Can this ceramic rod be used on all types of diamonds? Yes, it works on most diamonds. Natural diamonds and lab-made diamonds both polish well. Be careful with very soft diamonds though. Test a small hidden spot first. This avoids damage to valuable stones.

REQUEST A QUOTE

RELATED PRODUCTS

Cheaper Low Black and White and Customized Aluminium Spacer Bar for Insulating Glass

Corrosion Resistant Aluminum Nitride Ceramic Rod Special Ceramic Thread Rod and Bar made of Durable Materials

Ceramic Equipment Intelligent Electric Kiln Brick Kiln Domestic School Ceramic bar in High Temperature Ceramic Firing

High Purity White Ceramic Alumina Rod/Tube/Bar Wear Resistant Custom Industrial Ceramic Parts

Wear Resistance Zirconia Ceramic Stick Zro2 Ceramic Bar Zirconia Ceramic Rod