Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

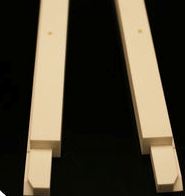

Overview of Easy Machinable Macor Ceramic bar Mica Glass Disc Wafer for Machining Sheet

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of Easy Machinable Macor Ceramic bar Mica Glass Disc Wafer for Machining Sheet

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of Easy Machinable Macor Ceramic bar Mica Glass Disc Wafer for Machining Sheet

Macor ceramic is special. You can machine it like metal. It does not require firing after machining. This material is strong. It takes care of heat quite possibly. Macor remains secure under abrupt temperature level adjustments. It stops power efficiently. It is non-porous. This ceramic withstands chemical attack. It functions accurately in hard settings.

We supply Macor in bar kind for machining. These bars allow you develop intricate forms quickly. Usage conventional metalworking tools. No special devices is needed. Achieve limited tolerances and fine details. This is best for prototypes and custom-made parts. Bars come in typical diameters. Sizes are generally 12 to 24 inches. Customized dimensions are possible.

Mica glass ceramic discs and wafer sheets are likewise readily available. These are pre-formed level pieces. They are excellent electrical insulators. They provide superb thermal insulation as well. Discs and wafers withstand high voltages. They do continually at extreme temperature levels. They are dimensionally stable. These components are ready for prompt usage.

The discs match applications needing electric separation. Utilize them in high-power electronics and sensing units. They separate warmth successfully. Wafers are thin, level sheets. They are suitable for substratums and spacers. Their smooth surface is excellent for specific settings up. You can reduce these wafers easily if needed. They preserve integrity under tension. Supply numerous densities and diameters.

Applications of Easy Machinable Macor Ceramic bar Mica Glass Disc Wafer for Machining Sheet

Machinable Macor ceramic bars and mica glass discs offer distinct remedies for tough jobs. Macor machines like metal. People make use of basic metalworking tools on it. This saves money and time. Facility forms are very easy to make. This is difficult with regular ceramics. Macor takes care of high warm well. It remains strong up to 1000 ° C. It insulates electrical power perfectly. It won’t shed or melt. It resists most chemicals also. These high qualities make Macor bars ideal for several uses. People make precision electric insulators from them. They develop custom components for lab devices. Semiconductor processing devices require Macor components. Aerospace systems make use of Macor for heat-resistant parts. Optical installs and fixtures typically use machined Macor.

Mica glass discs are slim sheets of machinable product. They are very flat and smooth. They resist high temperatures. They are excellent electric insulators. Individuals reduced these discs conveniently right into specific shapes and sizes. They pierce openings in them specifically. This makes them perfect for certain applications. People use them as view glasses in hot heaters. They work as windows in high-temperature tools. Electronic devices use them as shielding substratums. Accuracy tools need them as spacers or shims. They give electric isolation between parts. Individuals depend on their security under heat and anxiety. Both Macor bars and mica discs fix issues various other materials can not. They enable custom-made, high-performance components for demanding atmospheres. Industries like aerospace, electronics, and research utilize them daily.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Easy Machinable Macor Ceramic bar Mica Glass Disc Wafer for Machining Sheet

What is Macor?

Macor is a special ceramic. It’s made from mica glass. This makes it unique. You can machine it like metal. It’s very strong. It handles high temperatures well. It’s also an excellent electrical insulator. People use it where regular ceramics are too hard to shape.

Can you really machine Macor easily?

Yes, you can machine Macor easily. Use standard metalworking tools. Carbide tools work best. Diamond tools work too. Drilling, turning, milling, grinding are all possible. You get good precision. You get fine finishes. This saves time and cost. You avoid expensive ceramic sintering methods.

How hot can Macor get?

Macor handles high heat. It works continuously up to 800°C (1472°F). Short bursts can reach 1000°C (1832°F). Its strength stays good at high temperatures. It doesn’t melt. It doesn’t outgas much. It’s stable. This makes it good for furnaces, aerospace parts, and high-temperature sensors.

Is Macor good for electrical parts?

Macor blocks electricity very well. It’s a top-notch insulator. Its insulation stays strong even at high voltages. It stays good in high heat. It works in a vacuum. It resists arcing. This is why it’s used in electrical feedthroughs, insulators, and semiconductor tools.

Where is Macor used?

Macor goes into many demanding jobs. It’s common in aerospace for sensors and insulators. Semiconductor tools use it for wafer chucks and parts. Research labs use it in vacuum systems. It’s good for laser components. Medical devices use it. Industrial equipment uses it for high-heat electrical insulation. Its machinability lets designers make complex shapes.

REQUEST A QUOTE

RELATED PRODUCTS

Aircraft Grade Duralumin 2024 Aluminium Round Bars Customized 2024 Aluminum Rod

Quality Aluminium Spacer bar for Aluminum Frame Window

Custom Color Barbell Bar Competition Weightlifting Barbells Ceramic Coated Straight Powerlifting Barbell

High Precision Zirconia Ceramic Bar Rod for Industry

Customized Zirconia Ceramic Strip Bar for Industrial Ceramic Applications with Services of Cutting Bending & Welding