Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

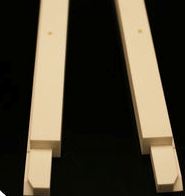

Overview of Electrical Insulation Machined Alumina Ceramic bar Strip

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of Electrical Insulation Machined Alumina Ceramic bar Strip

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of Electrical Insulation Machined Alumina Ceramic bar Strip

Right here’s the requirements for our electrical insulation machined alumina ceramic bar strips. These elements provide excellent performance for requiring electric applications. They are precision-machined from high-purity alumina ceramic product. This makes sure consistent high quality and reliable insulation.

The ceramic bars feature high dielectric strength. They effectively block high voltages stopping electrical existing leak. Their volume resistivity continues to be very high also at elevated temperatures. This makes them appropriate for hot atmospheres. Thermal security is an essential benefit. Benches hold up against temperatures approximately 1700 ° C( 3092 ° F)without deteriorating. They stand up to thermal shock from rapid home heating or cooling down cycles well.

Mechanical longevity is strong. Alumina ceramic is extremely tough and wear-resistant. It maintains its form and toughness under lots. The material supplies excellent chemical resistance. It endures assault from numerous acids, antacid, and solvents. This guarantees lengthy service life in extreme problems.

Criterion dimensions are offered. Typical measurements include density from 1mm to 20mm. Widths range from 5mm to 100mm. Sizes can be supplied up to 300mm or even more. Custom-made sizes and shapes are machined to exact drawings. Limited resistances are attainable. Normal machining resistance is ± 0.1 mm or finer on important dimensions. Surface coatings are smooth. This reduces friction and possible contamination.

The primary material make-up is 99% Alumina (Al2O3). This high pureness delivers ideal electrical and thermal buildings. Thickness is usually 3.9 g/cm FOUR. Flexural strength goes beyond 300 MPa. These bars are perfect for high-voltage insulators, feedthroughs, spacers, and bushings. They work well in heating systems, power electronics, sensors, and semiconductor devices.

Applications of Electrical Insulation Machined Alumina Ceramic bar Strip

Machined alumina ceramic bars and strips are crucial in electric applications. They offer exceptional insulation. This material stops electricity circulation really properly. It deals with high voltages safely. Alumina ceramic is incredibly tough. It resists deterioration well. It additionally deals with really heats. This security is important popular settings. Alumina resists chemical attack too. This makes it trustworthy lasting.

These ceramic components are common in high-voltage equipment. They act as solid, non-conductive assistances. They hold power lines and busbars securely. They stop harmful electric shorts. Alumina spacers isolate vital parts. They preserve safe voids between online components. This is important in switchgear and transformers.

Semiconductor manufacturing uses these bars extensively. They hold silicon wafers throughout handling. The high warm resistance is key here. Alumina remains secure in heating systems and plasma chambers. It does not pollute the delicate processes. Its purity is a significant benefit.

Welding devices relies on alumina insulation. These bars isolate welding ideas and nozzles. They withstand intense warm from the arc. They prevent current from going where it should not. This ensures regular welding efficiency. It protects the equipment structure.

Alumina strips are used in sensor housings. They secure delicate electronic devices from harsh problems. The electric insulation is best for this. Sensing units function properly without disturbance. The product guards them from heat and chemicals also.

Research laboratory devices benefits substantially. Alumina bars supply stable, inert systems. They support burner or examination examples. They don’t react with chemicals. They preserve honesty under thermal cycling. This dependability is necessary for precise results.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Electrical Insulation Machined Alumina Ceramic bar Strip

Here are 5 common questions about Electrical Insulation Machined Alumina Ceramic bars and strips:

What exactly are these alumina ceramic parts?

These are solid pieces made from aluminum oxide ceramic. Factories precisely shape them using machining tools. This process creates bars, strips, or custom forms. The material itself is very hard. It resists wear extremely well.

Why use alumina ceramic for electrical insulation?

Alumina ceramic does not conduct electricity. It acts as a powerful barrier against electrical current. This prevents shorts and sparks. It handles high voltages safely. Other materials might fail under similar stress.

How much heat can these parts handle?

They handle very high temperatures. Continuous use above 1000°C (1800°F) is typical. Sudden temperature changes usually don’t crack them. This makes them good for hot environments like furnaces or power systems.

Can you machine these parts to exact sizes?

Yes. That’s a key advantage. Suppliers machine the fired ceramic blocks precisely. This achieves tight tolerances and smooth surfaces. Complex shapes and holes are possible. You get parts ready to fit directly into your equipment.

How do they compare to plastic or other insulators?

Alumina ceramic is much stronger mechanically. It lasts longer under physical stress. It handles far higher temperatures. It resists chemical corrosion better than most plastics. It offers superior electrical insulation at extreme conditions. Plastic costs less but fails sooner in tough applications.

REQUEST A QUOTE

RELATED PRODUCTS

High Temperature Resistance Machined Custom 99 96 95 Alumina Zirconia Precision Industry Ceramic Rod Roller Bar

Custom Size High Quality Wear And Corrosion Resistant Alumina Ceramic Rod Needle bar

Polish Round End Alumina Zirconia Steatite Ceramic Rod Bars Made in China

High Polished Isostatic Pressured Yttria ZrO2 Ceramic Bar Zirconia Ceramic Rod

Hot 6061 6063 6082 7075 7A09 2024 2017 3003 T5 T6 T651 Alloy Aluminium Rod Custom Size Aluminum Flat Bar