Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

Overview of Factory s Customized 1050 1100 3003 5083 6061 6063 7075 Aluminum Alloy Bar Rod

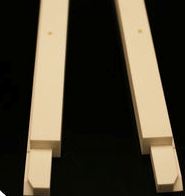

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of Factory s Customized 1050 1100 3003 5083 6061 6063 7075 Aluminum Alloy Bar Rod

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of Factory s Customized 1050 1100 3003 5083 6061 6063 7075 Aluminum Alloy Bar Rod

Our factory makes customized aluminum alloy bars and rods. We utilize usual qualities. These include 1050, 1100, 3003, 5083, 6061, 6063, and 7075. Each alloy has various staminas. Each alloy fits specific work. We form them into round bars, square bars, hex bars, and rectangular poles. You pick the shape.

We make bars in several sizes. Diameters begin extremely small. Sizes go up to large sizes. Lengths are additionally versatile. Inform us the specific size or width you need. Tell us the specific size you require. We reduced them to your specifications.

Surface area surface issues. We offer various choices. Mill coating is conventional. It comes straight from production. We additionally give polished finishes. These look really smooth. Anodized finishes add shade. Plated coatings safeguard against corrosion. We can apply other coatings also. Ask us about your surface needs.

Accuracy is essential. We manage the measurements tightly. Our tolerances satisfy industry requirements. We likewise satisfy tighter resistances if required. Inform us your resistance demands. We will certainly meet them.

These bars are utilized in lots of ways. 1050 and 1100 are very practical. They are good for general shaping. 3003 deals with corrosion well. It is frequently utilized in chemical settings. 5083 is solid in salt water. It is perfect for aquatic jobs. 6061 and 6063 are very typical. They stabilize toughness and workability. They are made use of in buildings and frameworks. 7075 is the toughest. It is utilized in aerospace. It is used where high anxiety happens.

We supply these customized bars for many fields. Manufacturing facilities utilize them. Construction jobs utilize them. Individuals making machines use them. Transport companies use them. DIY projects use them. We make exactly what your task needs.

Applications of Factory s Customized 1050 1100 3003 5083 6061 6063 7075 Aluminum Alloy Bar Rod

Manufacturing facility personalized light weight aluminum alloy bars can be found in prominent qualities like 1050, 1100, 3003, 5083, 6061, 6063, and 7075. These bars are solid metal poles formed for particular tasks. Various alloys have various toughness. Recognizing these strengths assists select the right bar.

1050 and 1100 light weight aluminum are really pure. They are soft and bend conveniently. They resist rust well. These bars are utilized for easy components requiring shaping, like reflectors or chemical tanks. They are additionally usual in food processing tools.

3003 aluminum is more powerful than 1100. It handles developing well. It also resists deterioration. This makes it helpful for containers, closets, and parts revealed to weather. It’s a useful option for several basic usages.

5083 light weight aluminum is renowned for marine usage. It fights deep sea rust remarkably well. It’s also strong, particularly when welded. Shipbuilders utilize it for hulls and decks. It’s additionally made use of in pressure vessels and transport components needing durability.

6061 and 6063 are the most common general-purpose alloys. 6061 is solid and equipments conveniently. It’s used for heavy-duty components like vehicle structures, equipment parts, and structural pieces. 6063 is somewhat weak however forms perfectly. It’s the top selection for architectural trim, home window structures, and furniture since it looks great after completing.

7075 aluminum is the toughest alternative right here. It matches some steels in toughness. It’s made use of where high stress and anxiety occurs, like aircraft installations, high-performance bike components, and requiring mechanical components. It does not resist deterioration along with others, so it often needs protective coatings.

Factories reduced, machine, and end up these bars to exact customer sizes. They provide the raw material needed for countless tasks. The ideal alloy bar conserves money and time. It makes certain the last part performs appropriately.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Factory s Customized 1050 1100 3003 5083 6061 6063 7075 Aluminum Alloy Bar Rod

Factory’s Customized Aluminum Alloy Bar Rod FAQs

1. Which aluminum alloy is right for my project?

We offer several alloys. Each has different strengths. 1050 and 1100 are very pure. They are good for forming or electrical uses. 3003 handles corrosion well. It’s stronger than 1100. 5083 is excellent for marine settings. It resists salt water. 6061 and 6063 are versatile. They are strong and weld well. People use them for structures and frames. 7075 is the strongest. It is used in aerospace. It’s harder to machine. Tell us your needs. We help pick the best alloy.

2. What custom sizes and shapes can you make?

We make round bars, square bars, and hex bars. We make many sizes. Diameters range from small to large. We cut lengths to your exact requirement. Tolerance is tight. Surface finish options exist. You can get mill finish or polished. Tell us your drawing. We make the bar fit.

3. How do you ensure quality?

Quality matters. We source good raw materials. Our production uses modern machines. We check the alloy composition. We test mechanical properties like strength. We inspect dimensions carefully. We look at the surface. We provide test reports. You know the bar meets standards.

4. What is the typical lead time?

Lead time depends. Stock items ship faster. Custom sizes take more time. Alloy choice affects time. Order size matters too. Small orders might be quicker. Large orders need more production days. We give a clear estimate after you order. We keep you updated.

5. Is there a minimum order quantity (MOQ)?

Yes, we have MOQs. The MOQ depends on the alloy. It depends on the size. It depends on the shape. Standard sizes often have lower MOQs. Very custom sizes might need more. Contact us with your specs. We tell you the MOQ fast. We try to be flexible.

REQUEST A QUOTE

RELATED PRODUCTS

Factory Whole 1060 1070 PURE Aluminum Rectangular Flat Bar 10mm 8mm 6mm Aluminum Busbar

High Wear-resisting Solid Rod Flat Alumina Ceramic bar for High Voltage Resistor

High Purity 99% Polishing Alumina Ceramic Round bar Alumina Ceramic Shaft Al2o3 Rod

Custom Al2o3 Alumina Zro2 Zirconia Ceramic Rod Bar for High Hardness Wear Resistant

Custom Diameter 1050 1100 Aluminum Alloy Round Rods Bars for Industry and Construction