Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

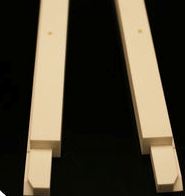

Overview of High Fine Quality AIN Ceramics Aluminium Nitride Ceramic Tube / Rod / Bar

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of High Fine Quality AIN Ceramics Aluminium Nitride Ceramic Tube / Rod / Bar

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of High Fine Quality AIN Ceramics Aluminium Nitride Ceramic Tube / Rod / Bar

Light Weight Aluminum Nitride (AIN) ceramic tubes, poles, and bars are top-notch components. They are developed for demanding commercial and electronic tasks. These porcelains manage severe warmth effectively. They can operate continually in temperatures getting to 1800 ° C. This makes them perfect for high-heat heaters and semiconductor tools.

Warmth moves via AIN porcelains incredibly quickly. Their thermal conductivity is about 170-180 W/mK. This is better than alumina. It allows heat spread swiftly and uniformly. This stops locations that damage equipment. It likewise cools electronic parts efficiently. They are exceptional electrical insulators also. They block high voltages securely. This is vital in power electronics and circuits.

These AIN components resist chemical assault highly. They won’t wear away conveniently from acids or bases. This suits them for rough chemical settings. They are also really tough and tight. They keep their shape under stress and high temperatures. This dimensional security is essential for precision components. Their surface area stays smooth and thick. This protects against leaks and contamination.

You discover these tubes, rods, and bars in lots of important areas. They are inside semiconductor processing machines. They operate in high-power LED systems. They serve in laser devices and high-frequency tools. They are utilized in vacuum chambers and thermal management systems. Their mix of warm handling, electric stopping, and stamina is hard to match.

Applications of High Fine Quality AIN Ceramics Aluminium Nitride Ceramic Tube / Rod / Bar

Light weight aluminum nitride ceramic tubes, poles, and bars offer extraordinary performance. This product deals with extreme heat very well. It moves heat away rapidly, better than lots of other ceramics. It also obstructs power totally. This mix is rare. It makes AIN parts vital for requiring technological jobs.

Electronic devices manufacturers rely upon these components. They require effective warm removal. AIN heat sinks draw heat from powerful computer chips. This stops getting too hot. The material also develops solid bases for electronic circuits. These substratums handle intense warmth during manufacturing. They keep circuits secure and secure. Semiconductor equipment makes use of AIN tubes and rods inside. These parts face warm, reactive gases. AIN stands up to deterioration and thermal shock. This makes certain lengthy equipment life and reliable processing.

The lighting market makes use of AIN as well. High-power LED lights generate considerable warmth. AIN places and housings draw this warm away effectively. This safeguards the delicate LED components. It extends the light’s life-span. It additionally maintains the light result strong and constant. Laser systems additionally profit. AIN components help cool vital laser parts. They take care of the intense heat generated throughout procedure. This prevents damage and keeps laser precision.

Industrial setups require durable sensing units. AIN rods and tubes offer well below. They safeguard temperature level sensing units in rough settings. Assume liquified metal handling or chemical processing. The product withstands high temperatures and chemical strike. It keeps the sensors functioning precisely. Aerospace and protection applications make use of AIN. Its electrical insulation is important. It isolates high-voltage components accurately. Its thermal management secures delicate electronic devices in limited spaces.

These AIN shapes are essential. They address difficult heat and electrical issues. Industries choose them for integrity under stress and anxiety. Their special traits allow sophisticated technology.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Fine Quality AIN Ceramics Aluminium Nitride Ceramic Tube / Rod / Bar

High Performance Aluminium Nitride Ceramics: Tubes, Rods, Bars – Key Questions

What makes Aluminium Nitride (AlN) ceramics special?

AlN ceramics offer exceptional thermal conductivity. They move heat far better than many other ceramics like alumina. This is crucial for keeping high-power electronics cool. Good electrical insulation is another key benefit. These properties make AlN ideal for demanding electronics and semiconductor tools.

How well does AlN conduct heat?

AlN conducts heat extremely well. Its thermal conductivity is much higher than alumina. Think 150-180 W/mK for high-purity AlN. This number beats many metals. It efficiently pulls heat away from sensitive components. Preventing overheating is vital for reliability.

Is AlN electrically insulating?

Yes, AlN is an excellent electrical insulator. Its electrical resistivity is very high. This property prevents dangerous current leaks. It ensures safe operation in electrical applications. You get electrical isolation plus superior heat dissipation.

What temperatures can AlN handle?

AlN withstands very high temperatures. It stays stable in air up to about 1300°C. In inert atmospheres, it handles temperatures over 1800°C. This thermal stability suits furnace parts, semiconductor processing, and high-heat environments. It won’t degrade easily under thermal stress.

Can AlN tubes, rods, and bars be machined?

Machining AlN is possible but challenging. The material is very hard. Precision machining requires diamond tools and expertise. We supply components in precise shapes like tubes, rods, and bars. Custom sizes and finishes are available. This minimizes the need for difficult post-processing.

How resistant is AlN to chemicals?

AlN offers good chemical resistance. It resists attack from most acids and alkalis. Molten metals generally don’t affect it. This stability makes it reliable in corrosive environments. It performs well in aggressive chemical processing or metal handling applications.

REQUEST A QUOTE

RELATED PRODUCTS

2024 Rod / Extruded Aluminum Alloy Bars

6061 7075 Aluminum Flat Bar Square Bar Zero Cut Profile-National Standard Extruded Aluminum Profile Bending Welding Processing

High Quality Aluminum 2A11 2024 3003 5052 5083 6061 6063 7075 T6 Aluminium Bar Alloy Aluminio Rod Round Bar in Stock

Aluminum Bar Aluminum Square Bar 1060 5052 5053 6061 Aluminum Round Bar

Customizable White 95 Alumina Ceramic Bar Shaft Wear Resistant Industrial Al2O3 Porcelain Knife Sharpening Rod