Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

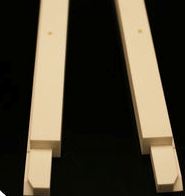

Overview of High Purity Aluminum Oxide Alumina Ceramic Square Block/Rod/Bar/Tube High Thermal Conductivity Industrial Ceramic Parts

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of High Purity Aluminum Oxide Alumina Ceramic Square Block/Rod/Bar/Tube High Thermal Conductivity Industrial Ceramic Parts

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of High Purity Aluminum Oxide Alumina Ceramic Square Block/Rod/Bar/Tube High Thermal Conductivity Industrial Ceramic Parts

High purity light weight aluminum oxide ceramic parts provide phenomenal efficiency. This material is over 99% pure alumina. That pureness makes certain top-tier residential properties. These parts handle extreme warmth very well. They stand up to temperature levels much beyond a lot of metals. Thermal shock resistance is another strength. They will not crack easily when temperatures alter quick. You get high thermal conductivity also. Warm steps successfully via blocks, poles, bars, and tubes. This makes them outstanding for taking care of heat.

Electric insulation is superb. These ceramics block electrical power totally. They are perfect for electrical applications needing seclusion. Mechanical toughness is impressive. Alumina components stand up to wear and abrasion roughly. They remain hard and challenging under pressure. Chemical resistance is superior. Acids, alkalis, and solvents don’t harm them. This guarantees long life in harsh setups.

Surface surface options exist. Components can be really smooth or left somewhat rougher. Precision machining is possible. You obtain precise measurements and limited tolerances. Lots of forms are offered. Square blocks, solid rods, rectangular bars, and hollow tubes prevail. Personalized forms are feasible too. These ceramics serve lots of requiring industries. Electronic devices use them for substrates and insulators. Semiconductor devices rely upon their purity and warmth handling. Laser systems need their thermal stability. Heater parts take advantage of their heat resistance. Industrial machinery utilizes them for wear components. Medical tools value their biocompatibility and stamina.

Applications of High Purity Aluminum Oxide Alumina Ceramic Square Block/Rod/Bar/Tube High Thermal Conductivity Industrial Ceramic Parts

High pureness light weight aluminum oxide ceramic components offer major advantages in tough jobs. These blocks, poles, bars, and tubes take care of extreme heat very well. They move warm away promptly. This is essential where things get intensely warm.

Semiconductor manufacturing uses these ceramics greatly. They hold silicon wafers during high-temperature procedures. The ceramic does not pollute the wafers. And also, it endures the warmth without damaging down. Furnace linings and supports made from alumina ceramic last much longer. They stand up to thermal shock much better than metal alternatives.

Laser systems require dependable components. Alumina ceramic laser tubes and placing blocks take care of intense warmth from the laser beam of light. This keeps the laser stable and exact. The material does not soak up the laser power either. Measurement equipment counts on stability. High purity alumina poles and bars provide this. They increase extremely little with temperature changes. This makes accurate measurements feasible.

Industrial wear is a constant issue. Alumina ceramic blocks and tubes fight wear effectively. They line chutes, guides, and bearings. Rough products cause less damage. The surface area remains smooth longer. Electrical insulation is one more vital advantage. Alumina ceramic components shield also at high voltages and temperatures. They separate elements in power electronics safely. Their strength includes mechanical support also.

Chemical resistance is very important. Acids and bases do not conveniently attack high purity alumina. This makes it appropriate for harsh chemical atmospheres. Pump seals and reactor parts benefit. The product stays undamaged. Engineers pick these porcelains for their combined residential or commercial properties. High thermal conductivity, strength, insulation, and security resolve hard troubles. They work where other materials fall short.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Purity Aluminum Oxide Alumina Ceramic Square Block/Rod/Bar/Tube High Thermal Conductivity Industrial Ceramic Parts

High purity alumina ceramic is a material. It is mostly aluminum oxide. The purity level is over 99%. It is very hard. It resists wear and corrosion. It is an electrical insulator. These traits suit tough industrial jobs.

What are the key properties? These ceramic parts are extremely hard. They are strong. They handle high temperatures well. They have high thermal conductivity. Heat moves through them fast. They resist chemicals. Acids and alkalis do not harm them. They insulate electrically. These features matter for industry.

Where are they used? They are in electronics. They act as substrates and insulators. Semiconductor plants use them for wafer handling. Furnace parts need them. They manage heat. Mechanical seals and bearings use them. Medical devices use them. Durability and purity are critical here.

Why is high thermal conductivity good? It pulls heat away. This stops overheating. Electronics stay cooler. High-temperature processes transfer heat quicker. This boosts efficiency. It lowers thermal stress. Parts last longer.

What shapes and sizes exist? We offer square blocks, rods, bars, and tubes. Sizes can be custom. Standard sizes are ready. Dimensions match the job. We make parts to exact specs.

REQUEST A QUOTE

RELATED PRODUCTS

Hot 99% 95% Alumina Ceramic Rod High Hardness Insulation bar / Rod

Factory s Customized 1050 1100 3003 5083 6061 6063 7075 Aluminum Alloy Bar Rod

Custom Wear Resistant Alumina Oxide Al2o3 Ceramic Rod Wear Resistant Aluminum Oxide Insulation bar

Hot New 7*16 Georgian bar with Plastic Accessory for Connect with Aluminum Spacer bar

High Temperature Resistance Machined Custom 99 96 95 Alumina Zirconia Precision Industry Ceramic Rod Roller Bar