Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

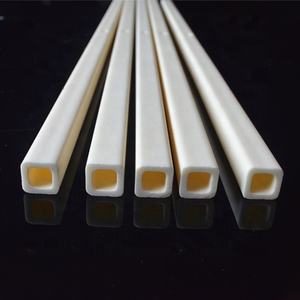

Overview of High Quality Premium Alumina Ceramic Parts Industrial Wear-Resistant Custom Accessories-Alumina Rod Cutting Welding

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of High Quality Premium Alumina Ceramic Parts Industrial Wear-Resistant Custom Accessories-Alumina Rod Cutting Welding

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of High Quality Premium Alumina Ceramic Parts Industrial Wear-Resistant Custom Accessories-Alumina Rod Cutting Welding

These alumina ceramic parts deliver major efficiency. They’re built difficult for commercial misuse. Solidity is a major stamina. Alumina ceramic beats most steels easily. This hardness implies outstanding wear resistance. Components last a lot longer in abrasive problems. You conserve cash on substitutes.

Heat resistance is an additional large plus. These parts handle extreme temperature levels. They won’t warp or compromise under high heat. This is essential for welding and cutting jobs. Dependability issues in warm environments.

Electric insulation is key. Alumina ceramic doesn’t perform electricity. It keeps employees secure around online circuits. This residential or commercial property is important for many electrical applications. You avoid unsafe shorts.

Chemical stability goes over. Alumina ceramic stands up to most acids and antacids. It doesn’t wear away like steel. Parts stay strong in severe chemical settings. No corrosion. Ever before.

We provide personalized shapes. Required specific rods, tubes, or complex parts? We can machine them precisely. Tell us your precise demands. We make it happen.

These components are best for requiring uses. Assume cutting devices, welding components, put on plates, shielding parts. They take care of friction, heat, stimulates, and chemicals. Performance remains constant.

Material high quality is non-negotiable. We make use of high-purity alumina powder. Sintering is thoroughly regulated. This makes sure thickness and toughness. You obtain parts you can rely on.

Surface finish alternatives are readily available. We can offer smooth finishes or details textures. The coating depends upon your application requires. Simply ask.

Dimensional precision is important. Our machining meets tight tolerances. Components fit flawlessly into your assemblies. You avoid installation migraines.

Applications of High Quality Premium Alumina Ceramic Parts Industrial Wear-Resistant Custom Accessories-Alumina Rod Cutting Welding

Premium quality costs alumina ceramic parts resolve hard industrial issues. They withstand put on extremely well. These porcelains take care of severe warmth without damages. They stay solid in very warm settings. Alumina is electrically insulating also. This makes it safe for electrical applications. Manufacturers form alumina specifically for requiring jobs. Parts like poles, tubes, and plates prevail. Customization is key. Manufacturing facilities make components to exact shapes and sizes needed.

Alumina ceramic rods are important devices. They excel in reducing and welding processes. Their firmness avoids quick wear. This gives a lot longer life span than metal choices. Continuous rubbing doesn’t weaken them promptly. They keep exact measurements over time. This makes certain constant high quality in production.

Welding uses alumina rods thoroughly. They work as long lasting get in touch with ideas. Place welding electrodes profit greatly. Alumina endures intense heat at the weld factor. It withstands staying with molten steel. This keeps the welding process smooth and dependable. Robot welding arms count on these challenging ceramic parts. Downtime for part substitute goes down considerably.

Trimming procedures require trustworthy overviews and sustains. Alumina poles supply excellent wear surface areas. Cord guides keep reducing paths exact. Abrasive slurry moves with alumina tubes without eroding them. Fixtures and jigs made from alumina remain dimensionally stable. They withstand consistent contact with hard products. This lowers maintenance frequency and expense.

The material provides chemical inertness. Rough chemicals will not rust it. Alumina won’t infect delicate procedures. It works well in aggressive industrial settings. Factories value its consistent efficiency. Custom-made creates fit specific machine needs flawlessly. Engineers choose alumina for reliability and long life in difficult places.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Quality Premium Alumina Ceramic Parts Industrial Wear-Resistant Custom Accessories-Alumina Rod Cutting Welding

Here are 5 FAQs about High Quality Premium Alumina Ceramic Parts Industrial Wear-Resistant Custom Accessories-Alumina Rod Cutting Welding:

What makes alumina ceramic rods good for cutting and welding? Alumina ceramic is extremely hard. It resists wear exceptionally well. This toughness is vital in harsh industrial settings. The material handles high temperatures easily. This prevents warping or damage during intense cutting or welding work.

Can I get custom sizes or shapes for my specific job? Yes. We specialize in custom fabrication. Tell us your exact requirements. We produce rods cut precisely to your dimensions. We can also create unique shapes needed for specialized tools or fixtures. Our focus is solving your specific wear problems.

How long do these alumina rods last compared to metal? They last much longer. Alumina ceramic is far harder than most metals. It resists abrasion significantly better. This means less frequent replacements. You save money over time. Downtime for part changes is reduced.

Is alumina ceramic fragile? Will it break easily? It is brittle. Handle it with care during installation. Avoid sharp impacts. Once properly mounted, it performs reliably. Its extreme hardness protects it from gradual wear. Proper handling prevents breakage issues.

What industries commonly use these alumina ceramic rods? Many industries rely on them. Metal fabrication shops use them for welding fixtures. Mining equipment needs wear protection. Chemical processing plants use them for corrosion resistance. Any application needing long-lasting, heat-resistant, wear-proof parts benefits.

REQUEST A QUOTE

RELATED PRODUCTS

Magnesium Alloy bar AZ31B AZ91D AZ80 ZK60A WE43 Mg Rod/bar Magnesium Round bar

Factory Direct Aluminum Round Bar Rod | High Strength Lightweight Industrial Grade | Anodized Surface | Custom Cut To Size

White YSZ ZrO2 Zirconia Ceramic Rod Shaft Bar

Hot Extruded Round Billet Aluminum Bar 60mm 6061 T6 Aluminium Rod

Aluminum Bar Aircraft Grade Aluminum Rod s