Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

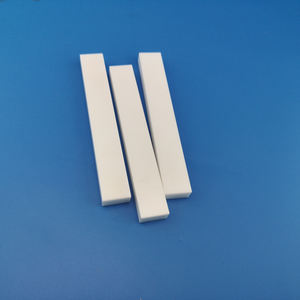

Overview of Industry Customized Advanced Technical White 96% Alumina Ceramic Parts bar

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of Industry Customized Advanced Technical White 96% Alumina Ceramic Parts bar

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of Industry Customized Advanced Technical White 96% Alumina Ceramic Parts bar

Here are the specifications for our Industry Customized Advanced Technical White 96% Alumina Ceramic Parts bar. This material offers exceptional performance for demanding applications. Alumina content is high, at 96%. This purity ensures excellent properties. The ceramic is very hard. It resists wear extremely well. Parts last longer under abrasive conditions. This saves money on replacements. The material handles high temperatures easily. It performs reliably up to 1700°C. Thermal shock resistance is good. Sudden temperature changes cause less cracking. Electrical insulation properties are superior. This is vital for electronic uses. Chemical inertness is another key benefit. The ceramic withstands most acids and alkalis. Corrosion is rarely a problem.

We customize these parts precisely for your needs. Tell us your exact dimensions. We machine the ceramic to tight tolerances. Complex shapes are possible. Surface finishes can be adjusted. We offer various polishing levels. We can provide specific roughness values. Mechanical strength is high. Alumina ceramic parts handle significant loads. They resist bending and breaking. This is crucial for structural components. The material is very stiff. It shows minimal deflection under force. Weight is low compared to metals. This aids in reducing overall system mass. Installation is often simpler.

Applications span many industries. These parts are ideal for wear components. They work well in pumps, valves, and seals. Semiconductor manufacturing uses them frequently. Furnace linings benefit from the heat resistance. Electrical insulators in high-voltage equipment rely on them. Chemical processing equipment needs their corrosion resistance. Medical devices utilize their biocompatibility. Our advanced technical white alumina ceramic provides a reliable solution. It meets strict industrial requirements.

Applications of Industry Customized Advanced Technical White 96% Alumina Ceramic Parts bar

These alumina ceramic parts are tough. They handle extreme conditions well. We make them specifically for industrial needs. The 96% alumina content gives excellent performance. These parts resist wear very effectively. They withstand high temperatures easily. Chemical corrosion doesn’t damage them. Electrical insulation is another key feature. Their smooth surface reduces friction. This material stays dimensionally stable under stress. It doesn’t warp or shrink much.

Many industries rely on these custom ceramic parts. Mining equipment uses them for wear plates and liners. They protect machinery from abrasive materials. Pump seals and valves made from alumina last much longer. The material handles corrosive fluids reliably. Electronics manufacturing needs precise insulators. Alumina parts provide stable electrical isolation. Semiconductor processing uses them for critical components. They endure high heat and aggressive chemicals. Medical devices use alumina for its biocompatibility. Surgical tools and implants benefit from its strength and smoothness.

Metal forming and welding fixtures need durability. Alumina parts withstand constant heat and pressure. They maintain precise shapes over time. Textile guides made from alumina reduce fiber wear. This improves production quality significantly. Furnace components face extreme temperatures daily. Alumina parts handle this easily. They don’t degrade like other materials. Laser systems use alumina for precise positioning components. The material reflects light well and stays cool. Food processing equipment values alumina’s inertness. It doesn’t contaminate products and cleans easily. Custom shapes are possible for specific machinery needs. We machine these parts to exact customer drawings. This solves unique engineering problems effectively.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Industry Customized Advanced Technical White 96% Alumina Ceramic Parts bar

What makes this 96% alumina ceramic special?

It’s very hard. It handles extreme heat well. It resists wear and chemicals strongly. These traits make it perfect for tough industrial jobs. It lasts longer than many other materials.

Can you make custom shapes and sizes?

Yes. We specialize in custom parts. We make complex shapes to your exact drawings. We work from prototypes to big production runs. We meet your specific design needs.

How durable is it really?

It’s extremely durable. It resists scratching and abrasion superbly. It doesn’t wear down easily under heavy friction. It handles sudden temperature changes without cracking. This toughness means less downtime and lower replacement costs.

Where is this ceramic used most?

It’s vital in harsh settings. Common uses include wear parts in mining equipment. It lines pumps handling abrasive slurries. It insulates high-temperature furnaces. It serves as critical components in semiconductor tools. It works in chemical plants resisting corrosion.

How quickly can I get samples or production parts?

We understand time matters. We offer relatively fast lead times for prototypes and production. Tell us your project details. We’ll give you a realistic delivery schedule. We aim to meet your deadlines without compromising quality.

REQUEST A QUOTE

RELATED PRODUCTS

99 99.5 Alsint Alumina Ceramic Grinding Drilling Long Bar Alumina Ceramic Stick

Hot s Stainless Steel Hexagonal Bars Stainless Steel Black bar

Factory Whole 1060 1070 PURE Aluminum Rectangular Flat Bar 10mm 8mm 6mm Aluminum Busbar

Aluminium Bar Alloy Rod Aluminum Round Bar In Stock

Industrial heating alumina ceramic rods/Al2O3 bar